|

Differential, Overhaul

|

Disassemble

Disassemble

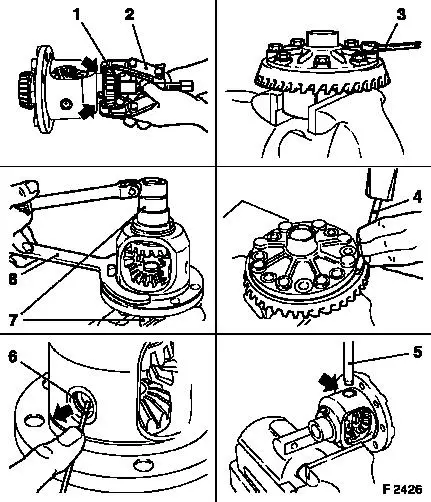

Remove differential – see operation "Rear Differential,

Disassemble". Clamp differential in vice. Remove tapered roller

bearing using KM-161-B (2) in conjunction with KM-621-18 (1). Apply

remover hook of KM-161-B (2) in recesses (arrows). Unscrew

fastening bolts (3) of ring gear. Remove ring gear from

differential with soft metal drift (4). Drive out differential

shaft from plane side (arrow) with suitable remover (5). Lever

retaining ring (6) from differential shaft. Clamp KM-621-25 (7) and

place ring gear side of differential on special service tool.

Insert counterpart of KM-621-25 (7) in differential from above.

Counterhold differential with KM-160 (8) and unscrew differential

pinion gears by turning KM-621-25 (7).

|

|

|

Clean Clean

Clean all components that are going to be reused.

Inspect

Inspect

Visually inspect all components for wear and damage.

Assemble

Assemble

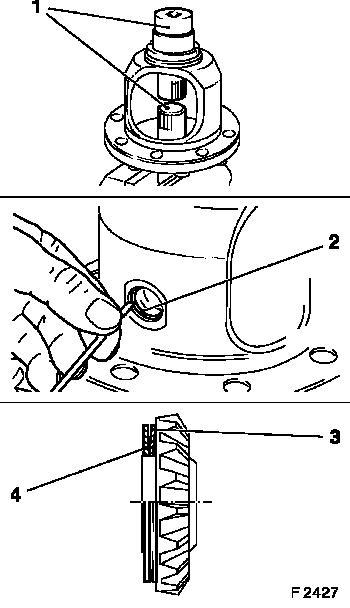

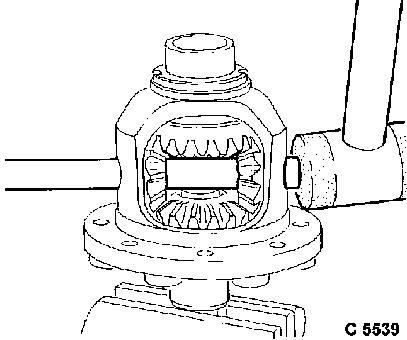

Place housing of differential on Tool KM-621-25 (1) clamped in

vice with ring gear side downwards.

Install new retaining ring (2) in differential housing.

Place one belleville spring (3) and one shim (4) on each drive

shaft ring gear. The difference in thickness between the two shims

must not exceed 0.1 mm.

|

|

|

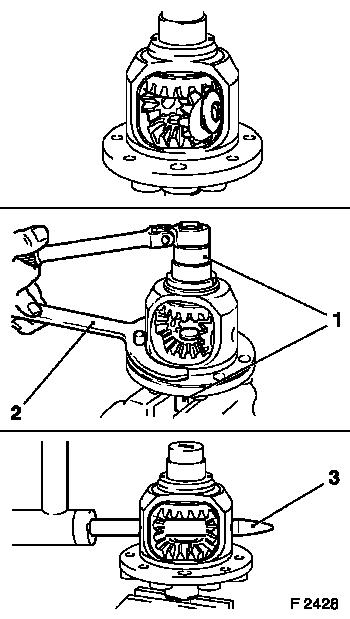

Place drive shaft pinion gears with shims and belleville springs

in differential housing on KM-621-25. Engage differential pinion

gears in splines of drive shaft pinion gears and align so that they

are exactly opposite each other. Before screwing in differential

pinion gears, move ball washers forwards in screw-in direction and

guide into their seats, so that they do not get tilted on the

differential housing.

Counterhold differential with KM-160 (2) and screw in

differential pinion gears by turning KM-621-25 (1).

|

|

|

After screwing in differential pinion gears, drive KM-621-26

into the differential housing with the point towards the retaining

ring side of the differential housing using a plastic hammer,

aligning hole patterns of the washer and differential pinion gears

to the housing if necessary.

Caution

Drive in KM-621-26 (3) with a plastic hammer only to avoid

formation of burrs.

|

|

|

Measure

Measure

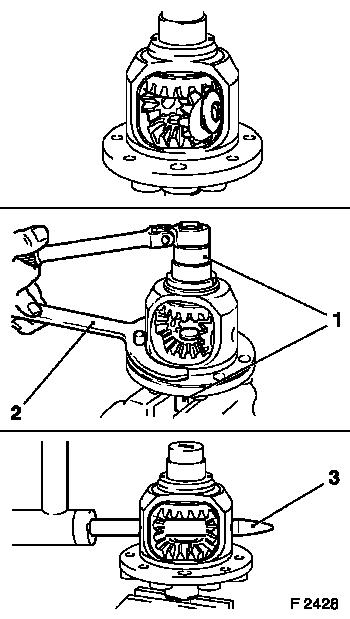

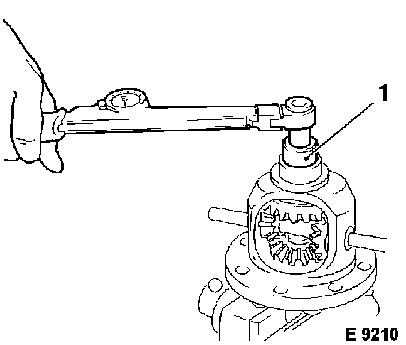

Using torque wrench and KM-621-25 (1), measure slip torque of

differential. If the measured torque is too low or high, install a

thicker or thinner shim under the axle shaft pinion gear. To do

this, disassemble the differential again and reassemble as

described above with the new shims. Ensure that the difference in

thickness between the shims under the axle shaft pinion gears does

not exceed 0.1 mm.

Torque

Permissible torque: 15 to 30 Nm / 11 to 22 lbf. ft.

|

|

|

Assemble

Assemble

Push KM-621-26 through differential housing with differential

shaft, ensuring correct positioning of the shaft – groove to

retaining ring. When the differential shaft projects no more than

approx. 1 cm from differential housing, hold KM-621-26 by hand and

drive differential shaft rapidly over retaining ring, so that it

engages in the groove of the differential shaft.

|

|

|

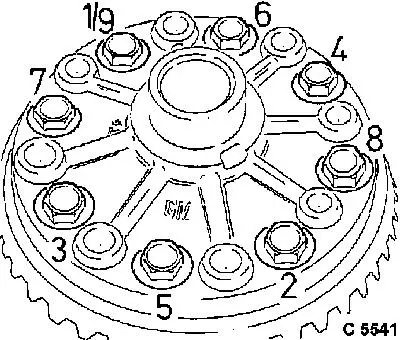

Place ring gear on a heating plate and heat to approx. 100

°C. To determine temperature, use thermochrome pencils or

suitable temperature gauge. After attaining temperature, place ring

gear on differential housing, install fastening bolts and tighten

in order shown.

Torque

Ring gear to differential – 115 Nm / 85 lbf. ft.

|

|

|

Assemble

Assemble

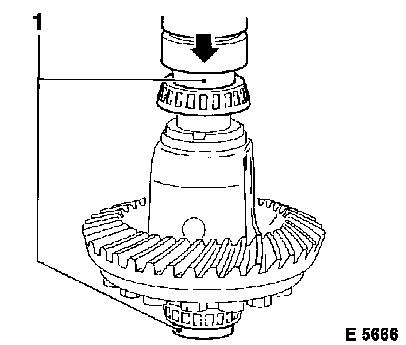

Press tapered roller bearing onto differential housing with

KM-273 (1).

Install differential – see operation "Rear Differential,

Assemble".

|

|

|