|

Toothed Belt, Remove and Install

|

General Instructions:

Install toothed belt on cold engine

(room temperature) only. Replacement of toothed belt must be

documented on dedicated sticker. The new toothed belt has guide

marks which must be observed on installation.

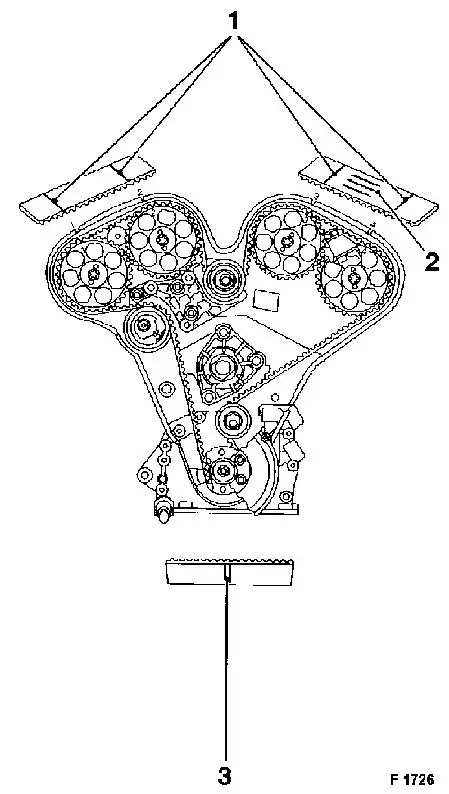

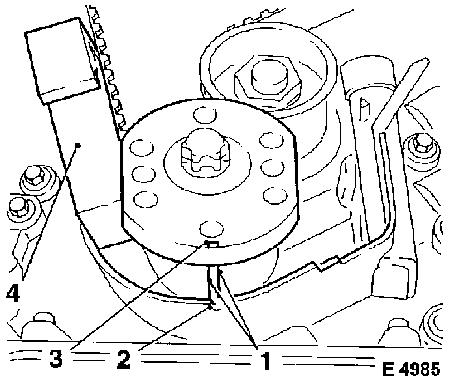

| 1. |

Single dash for camshaft sprockets. |

| 2. |

Arrow marks indicating the running direction. |

| 3. |

Double dash for toothed belt drive gear. |

If these guide marks are no longer visible, the toothed belt

must be replaced.

Caution

Do not remove toothed belt under any circumstances unless

camshaft sprockets and toothed belt drive gear have been adjusted

and locked in "TDC" position using KM-800. Improper assembly of

toothed belt can lead to engine damage. Misalignment of one tooth

on a toothed belt can cause damage to valves and pistons. Always

turn crankshaft uniformly in engine rotational direction.

|

|

|

Required special service tools:

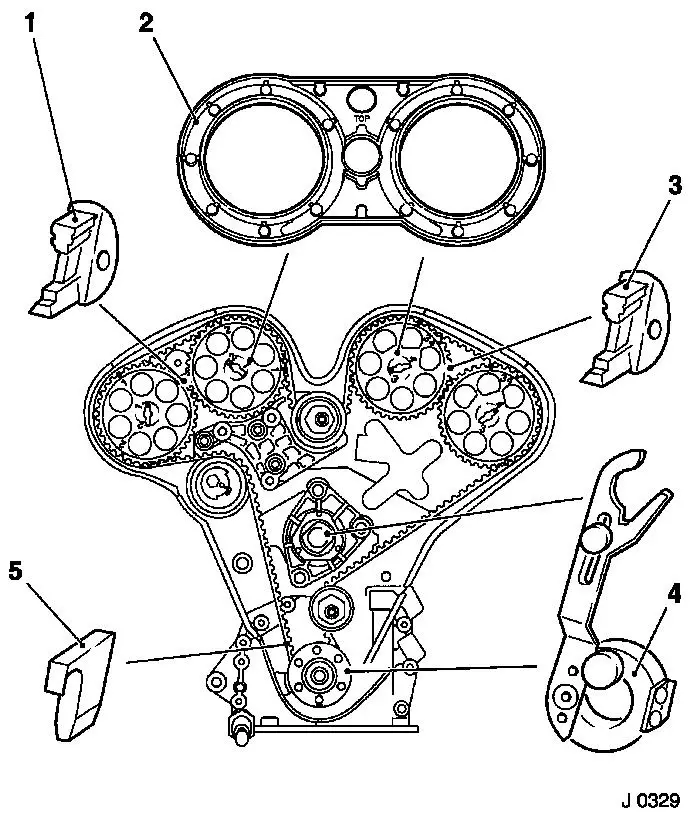

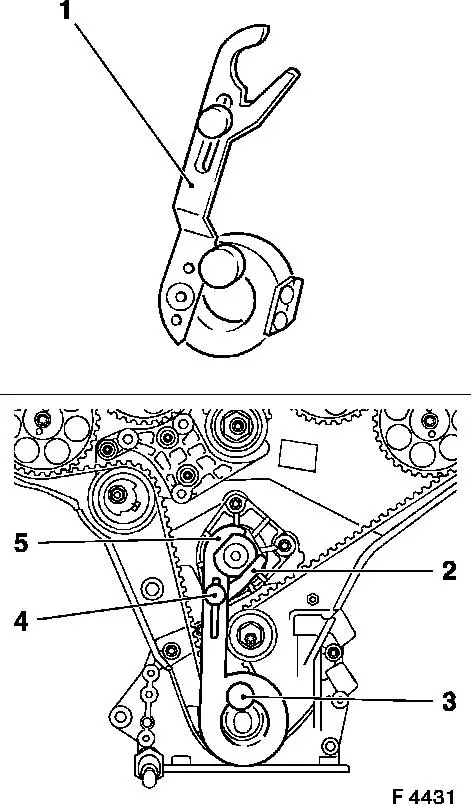

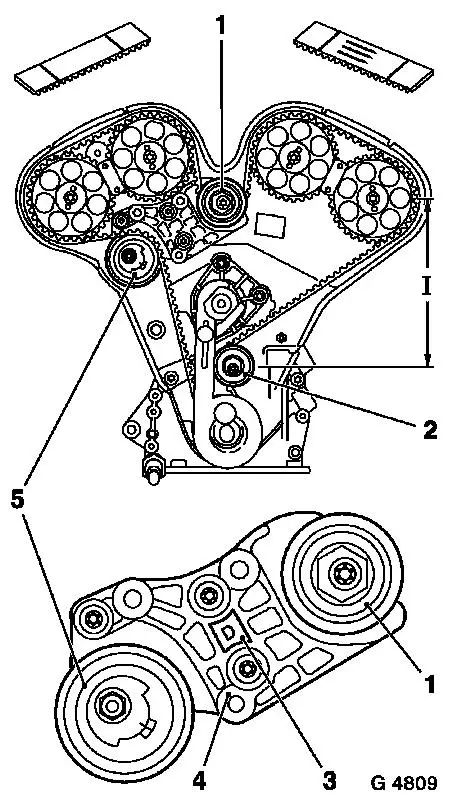

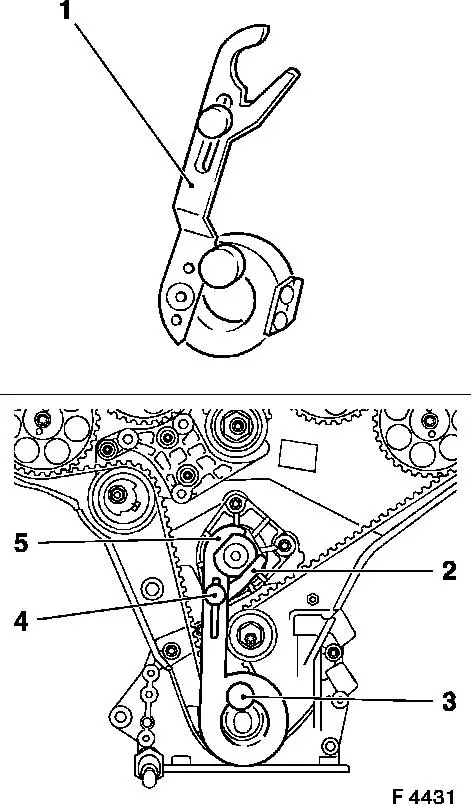

| 1. |

KM-800-1 (red) |

| 2. |

KM-800-20 |

| 3. |

KM-800-2 (green) |

| 4. |

KM-800-10 |

| 5. |

KM-800-30 |

|

|

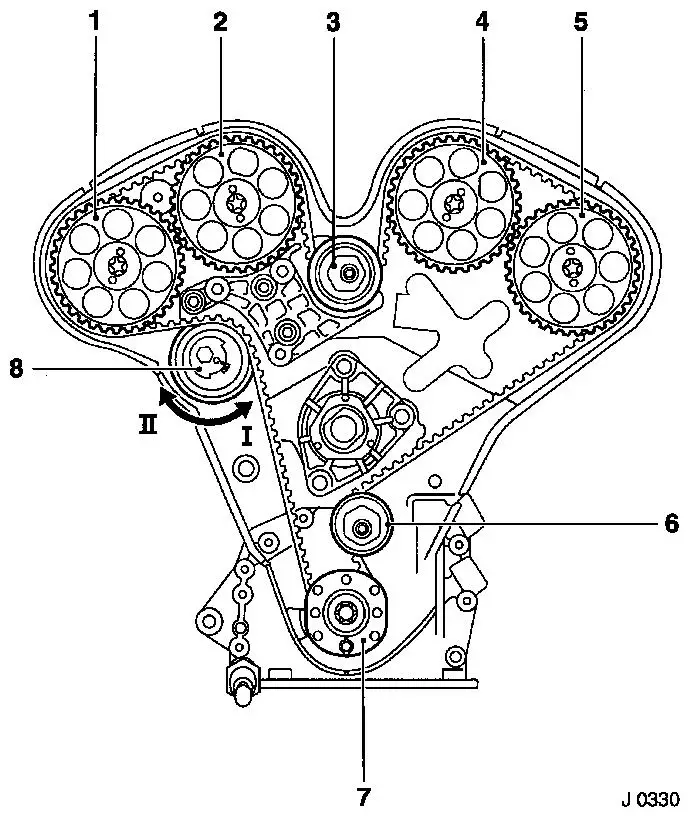

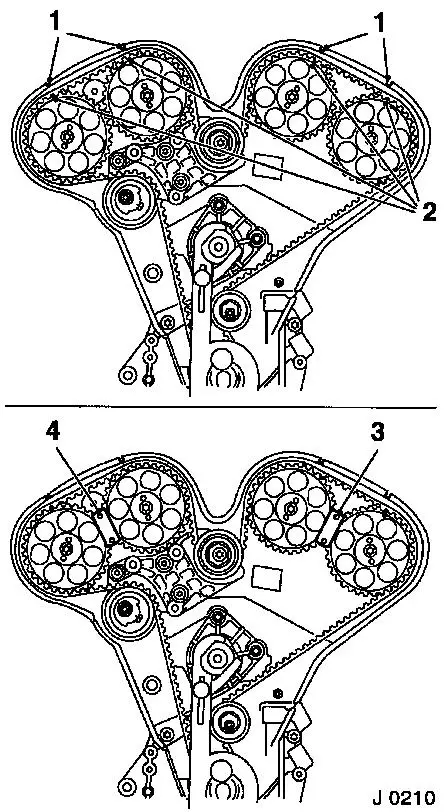

| 1. |

Camshaft sprocket "1" for cylinder 1-3-5

(exhaust) |

| 2. |

Camshaft sprocket "2" for cylinder 1-3-5

(intake) |

| 3. |

Toothed belt guide roller for adjustment of

camshaft sprockets for cylinders 1-3-5 |

| 4. |

Camshaft sprocket "3" for cylinder 2-4-6

(intake) |

| 5. |

Camshaft sprocket "4" for cylinder 2-4-6

(exhaust) |

| 6. |

Toothed belt guide roller for adjustment of

camshaft sprockets for cylinders 2-4-6 |

| 7. |

Toothed belt drive gear |

| 8. |

Toothed belt tension roller |

- Tension toothed belt

- Release toothed belt

|

|

|

Remove Remove

Remove front toothed belt cover – see operation "Front

Toothed Belt Cover, Remove and Install".

Remove torsional vibration damper – counterhold at

fastening bolt of toothed belt drive gear.

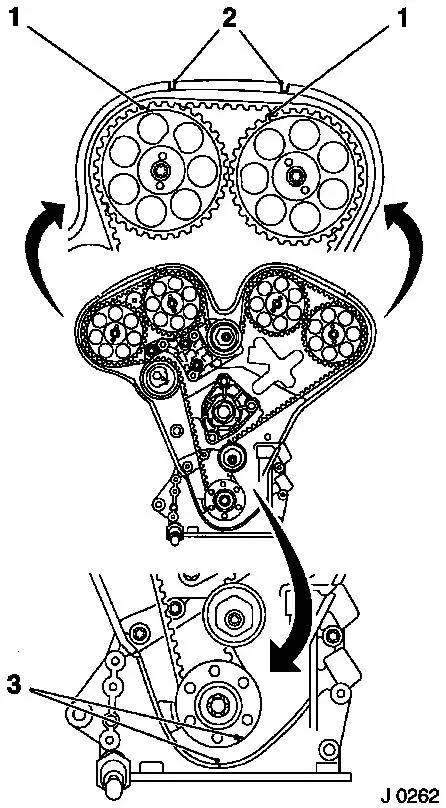

Adjust Adjust

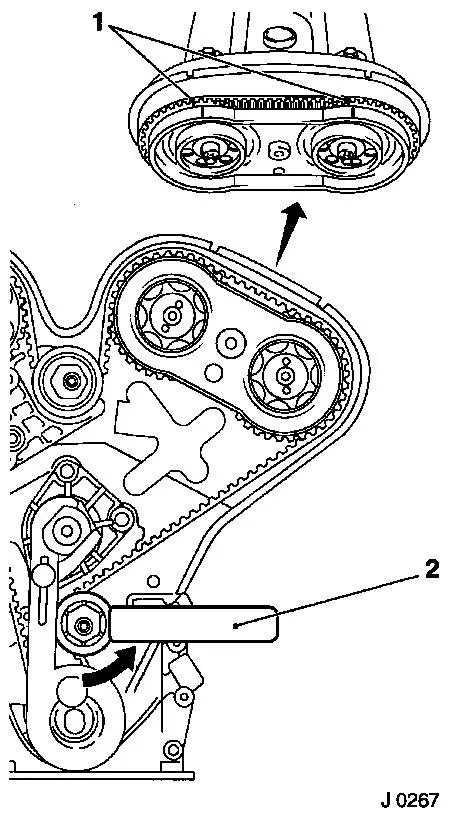

At the fastening bolt of the toothed belt drive gear, turn

crankshaft in engine rotation direction to just before TDC point

mark (3) – turn crankshaft slowly and smoothly.

Notches on camshaft sprockets (1) are just in front of marks (2)

on rear toothed belt cover.

|

|

|

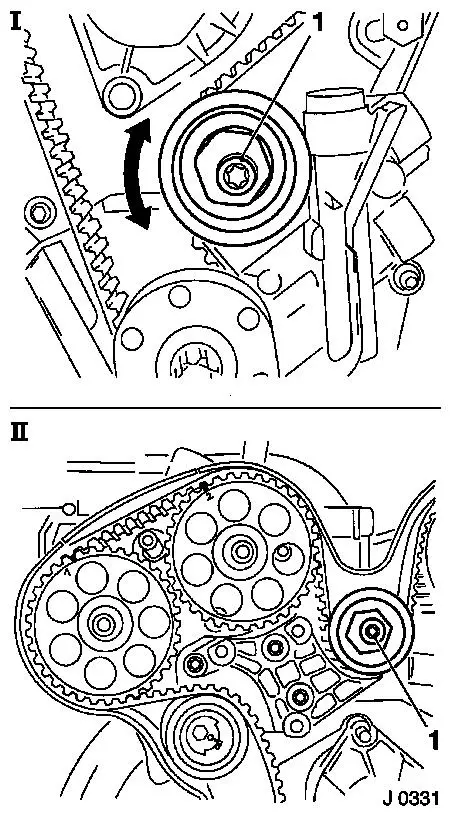

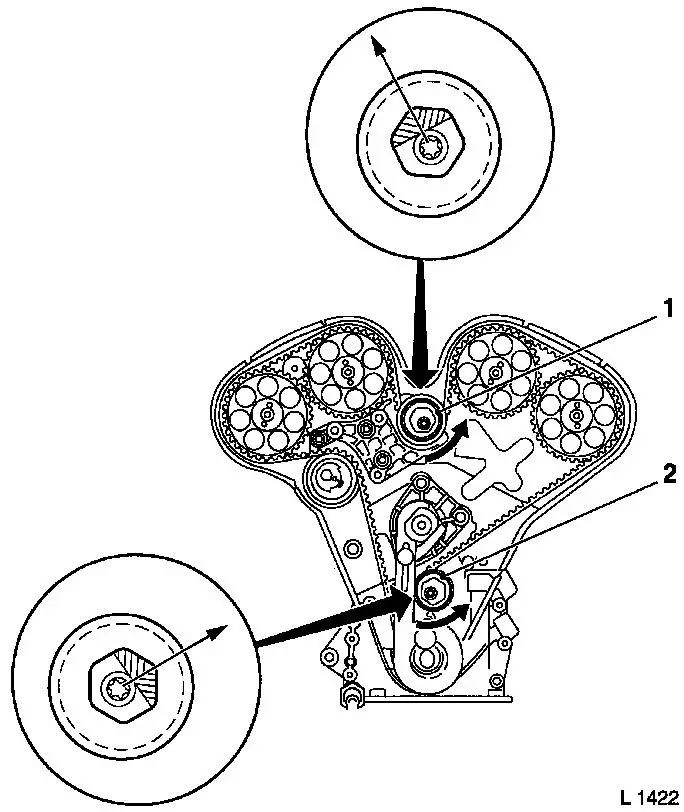

Install

Install

Bolt KM-800-10 (1) to toothed belt drive gear with knurled bolt

(3). Turn crankshaft further in engine rotational direction until

lever (5) contacts coolant pump flange.

Press movable lever (2) of KM-800-10 onto flattening of coolant

pump flange and tighten knurled bolt (4).

Note: The crankshaft

is now locked in the TDC position.

|

|

|

Inspect

Inspect

Marks (2) on camshaft sprockets align with notches (1) on rear

toothed belt cover.

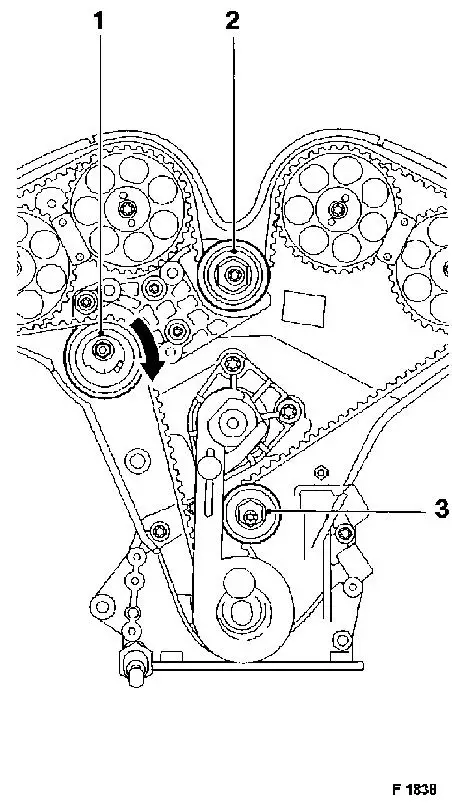

Install

Install

Fix camshaft sprockets in position.

Camshaft sprockets "3" and "4" with KM-800-2 (3) (green handle).

Camshaft sprockets "1" and "2" with KM-800-1 (4) (red handle).

Note: Insert

KM-800-1/-2 into camshaft sprockets with the designation "TOP" on

top.

|

|

|

Inspect

Inspect

I: If KM-800-2 (green handle) does not fit in the splines of the

camshaft sprockets, loosen toothed belt guide roller (1) and turn

the eccentric with MKM-6038 until KM-800-2 can be inserted.

II: If KM-800-1 (red handle) does not fit in the splines of the

camshaft sprockets, loosen toothed belt guide roller (1) and turn

the eccentric with MKM-6038 until KM-800-1 can be inserted.

|

|

|

Remove Remove

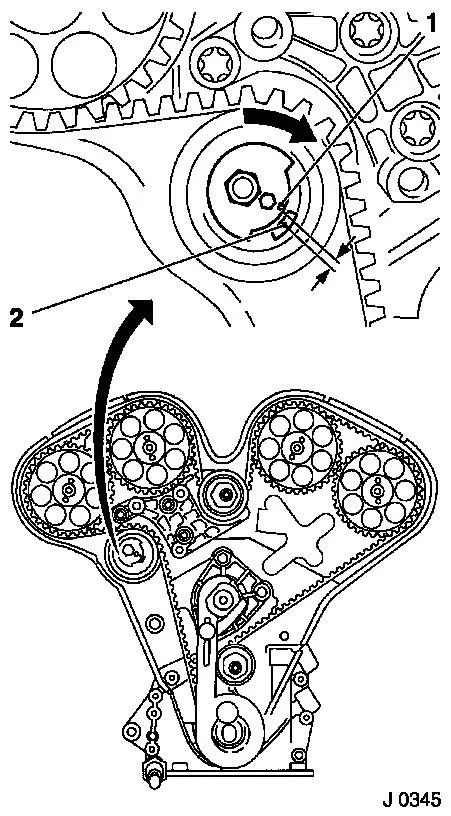

Loosen toothed belt tension roller.

Release toothed belt via toothed belt tension roller (1)

over-tension again at eccentric (inner hex – A/F 5) in

direction of arrow (clockwise) until eccentric reaches right

stop.

Tighten toothed belt tension roller (1).

Loosen toothed belt guide rollers (2) and (3).

Remove toothed belt.

|

|

Caution

Before installation, the toothed belt must be checked for

kinking and fissures and must be replaced if necessary. If any of

the guide marks on the toothed belt are no longer visible, then the

toothed belt must be replaced as well. The same applies to toothed

belts, toothed belt guide rollers and toothed belt tension rollers

which are contaminated with oil. Install the toothed belt on a cold

engine – room temperature.

|

Install

Install

Install new toothed belt.

Note running direction of toothed belt – arrow marks on

toothed belt point in engine rotational direction (clockwise).

Double dash (1) on toothed belt must align with groove (2) on

oil pump and notch (3) on toothed belt drive gear.

To prevent toothed belt jumping during installation, wedge

KM-800-30 (4) between oil pump and toothed belt drive gear.

|

|

Caution

|

There are various sequences for installing the toothed belt due

to the various base plate assemblies (4) (toothed belt tension

roller, toothed belt guide roller and base plate). The toothed belt

tension roller and toothed belt guide roller can only be replaced

as an assembly together with the base plate. It is essential that

the appropriate toothed belt is installed for the base plate

assembly.

Option 1:

Toothed belt tension roller (5) without front flanged wheel and

with code letter "D" (3) on the base plate (4) – 60.000 km /

4 years.

Install

Install

Position toothed belt via toothed belt guide roller (2) and

camshaft sprocket "4" and "3" – make sure that torsion side

(I) is tensioned – the excursion of the tension side of the

toothed belt between the toothed belt guide roller and camshaft

sprocket "4" should not exceed 1 cm.

The positioning marks (one dash each) on the toothed belt must

align with the notches of the camshaft sprockets and rear toothed

belt cover. Install toothed belt above toothed belt tension roller

(1) camshaft sprocket "2" and "1" as well as toothed belt tension

roller (5).

|

|

|

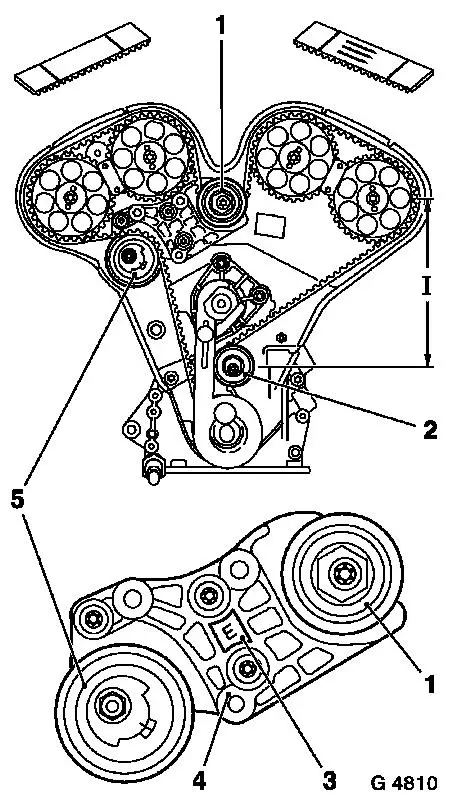

Option 2:

Toothed belt tension roller (5) without front flanged wheel and

with code letter "E" – "EA" (3) etc. or code number "01" on

the base plate (4) – 120.000 km / 8 years.

Install

Install

Position toothed belt on toothed belt tension roller (5) and

camshaft sprocket "1" and "2", toothed belt guide roller (1),

camshaft sprockets "3" and "4" and toothed belt guide roller (2)

– ensure that tension side (I) is taut – the deflection

of the toothed belt tensioned side between the toothed belt guide

roller and camshaft sprocket "4" should not exceed 1 cm.

The positioning marks (one dash each) on the toothed belt must

align with the notches of the camshaft sprockets and rear toothed

belt cover.

|

|

Caution

|

Adjustment of the toothed belt tension always starts at the

toothed belt guide roller (2).

Adjust Adjust

Turn eccentric of toothed belt guide roller (2) with MKM-6038 in

direction of arrow (anti-clockwise) until the pointer of the

eccentric (arrow) is at approx. "2 o'clock". Tighten toothed belt

guide roller (2).

Adjust toothed belt guide roller (1) – turn eccentric of

toothed belt guide roller (1) with MKM-6038 in direction of arrow

(anti-clockwise) until the pointer of the eccentric (arrow) is at

approx. "11 o'clock". Moderately tighten toothed belt guide

roller.

|

|

|

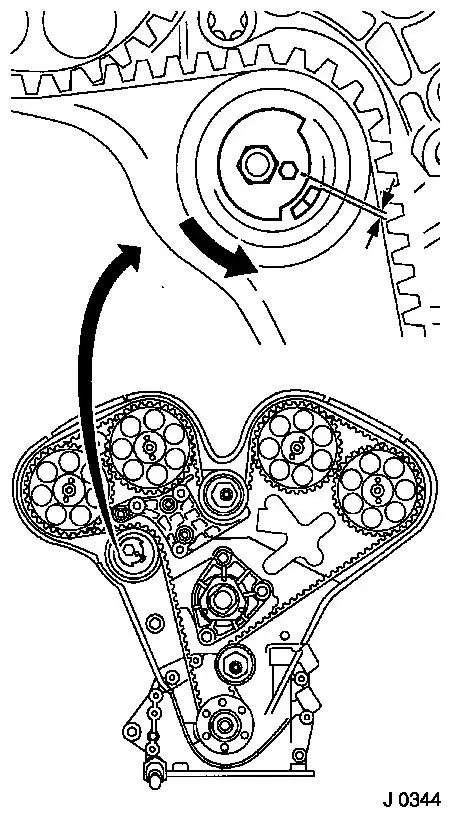

Loosen toothed belt tension roller.

Over-tension toothed belt via toothed belt tension roller

over-tension again at eccentric (inner hex – A/F 5) in

direction of arrow (anti-clockwise) until it just reaches stop and

allow to slide back until a measurement of approx. 1 mm is attained

(see Illustration J 0344).

Tighten toothed belt tension roller.

Remove Remove

Remove all retaining and adjusting tools.

Adjust Adjust

At the fastening bolt of the toothed belt drive gear, turn

crankshaft two turns (720°) in engine rotation direction until

just before TDC point mark – turn crankshaft slowly and

smoothly.

|

|

Install

Install

|

Bolt KM-800-10 (1) to toothed belt drive gear with knurled bolt

(3). Turn crankshaft further in engine rotational direction until

lever (5) contacts coolant pump flange.

Press movable lever (2) of KM-800-10 onto flattening of coolant

pump flange and tighten knurled bolt (4).

|

|

|

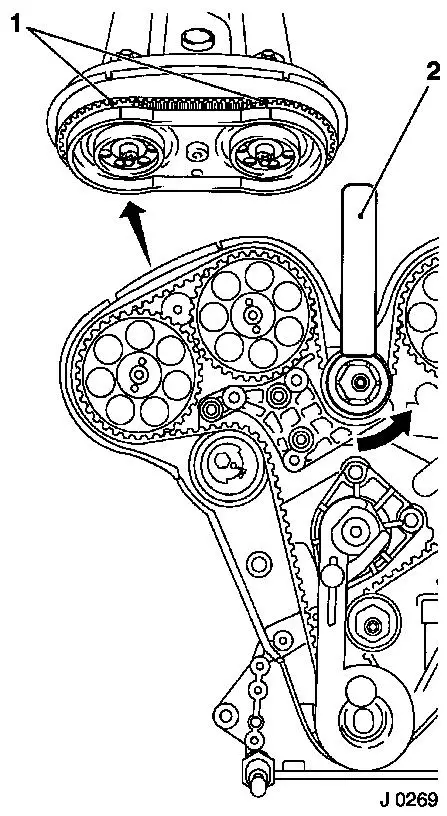

Adjust Adjust

Place Test Gauge KM-800-20 on camshaft sprockets "3" and "4"

(cylinder 2-4-6).

Marks (1) are located in front of the with marks on Test Gauge

KM-800-20 (i.e. in front of TDC mark).

Turn eccentric of toothed belt guide roller with MKM-6038 (2) in

direction of arrow (anti-clockwise) until marks (1) of camshaft

sprockets align with those of Test Gauge KM-800-20 – cone end

of eccentric is now positioned at approx. "12 o'clock".

Tighten toothed belt guide roller and remove Test Gauge

KM-800-20.

|

|

|

Caution

Adjustment of camshaft sprockets 1 and 2 (cylinder 1-3-5) may

only be commenced once camshaft sprockets 3 and 4 (cylinders 2-4-6)

have been exactly adjusted.

Adjust Adjust

Place Test Gauge KM-800-20 on camshaft sprockets "1" and "2"

(cylinder 1-3-5).

Marks (1) are located in front of the with marks on Test Gauge

KM-800-20 (i.e. in front of TDC mark).

Turn eccentric of toothed belt guide roller in direction of

arrow (anti-clockwise) with MKM-6038 (2) until the marks (1) on the

camshaft sprockets align with those on Test Gauge KM-800-20 –

pointer of eccentric is now at approx. "9 o'clock" position.

Tighten toothed belt guide roller and remove Test Gauge

KM-800-20.

|

|

|

Release toothed belt tension roller and over-tension again at

eccentric (inner hex – A/F 5) until it just reaches the stop

(anti-clockwise) and allow to slide back in direction of arrow

(clockwise) until mark (1) is located approx. 3 to 4 mm above mark

(2).

Tighten toothed belt tension roller – tightening torque 20

Nm / 15 lbf. ft.

Tighten toothed belt tension roller – tightening torque 40

Nm / 30 lbf. ft.

Remove Remove

Remove all retaining and adjusting tools.

Adjust Adjust

At the fastening bolt of the toothed belt drive gear, turn

crankshaft two rotations (720°) in engine rotational direction

to TDC mark. Turn crankshaft slowly and smoothly.

Fit KM-800-10 again. Using Test Gauge KM-800-20, check

adjustment of all camshaft sprockets, if necessary repeat adjusting

procedure, starting at camshaft sprockets for cylinders 2-4-6

– see operation "Timing, Adjust".

|

|

Note: The dash marks

on the toothed belt do not align with the camshaft sprocket notch

marks after one or more engine revolutions – they are only

used for installation!

Remove Remove

Remove KM-800-10 and KM-800-20.

Install

Install

Install torsional vibration damper – counterhold on the

fastening bolt for the toothed belt drive gear – tightening

torque 20 Nm / 15 lbf. ft.

Install front toothed belt cover – see operation "Front

Toothed Belt Cover, Remove and Install".

|