Function

The DDE 2.1 allows precise regulation of the injection

amount and injection timing in all operating conditions. This keeps fuel

consumption and exhaust emissions to a minimum.

The components of the DDE 2.1 can be divided into

three groups:

- Control unit

- Sensors

- Actuators

The control unit (55 - pin) processes the input signals

with microprocessors and uses fixed programmed data to calculate the required

output variables.

If the DDE 2.1 should malfunction, replacement

values are available, e. g. for malfunctions of the coolant temperature sensor,

charge air temperature sensor, charge pressure sensor or the start of injection

sensor.

Limited operation is maintained,

This also applies to malfunctions in the pedal position

sensor, injection adjustment solenoid valve, cranskhaft pulse pick - up,

control unit or faulty start of injection regulation.

If sensors or actuators should malfunction, which could

result in damage to the engine or to uncontrolled operation, the injection

system is switched off and thus the engine stopped.

As soon as the system functions correctly again, the

replacement values and / or emergency program are suspended.

- Start of injection regulation:

The start of injection is regulated by the injection adjuster

in the injection pump. A pulsed solenoid valve modulates the inner pump

pressure on one side of the injection adjuster, leading to the setting of a

defined start of injection. When not powered, the solenoid valve is closed,

which leads to early start of injection. The actual start of injection value is

reported to the DDE 2.1 control unit by the start of injection sensor

- Injection quantity regulation:

Injection quantity regulation is made possible by the

quantity actuator in the injection pump.

An electromagnetic rotary actuator is actuated, which moves

an eccentrically arranged ball pin. The rotary motion is converted into a

linear movement which acts on the control valve, varying the effective stroke

of the pump piston (injection quantity).

The position of the control valve is reported to the control

unit by the actuator sensor. If necessary, it can be adapted until the voltage

quantity nominal value is attained.

When not powered, the actuator is reset to zero output.

The start quantity regulation controls the injection amount

required for starting and for engine speed increase, depending on the engine

temperature, time and engine speed.

The amount of fuel injected in operation depends on the

position of the pedal position sensor and the engine condition

|

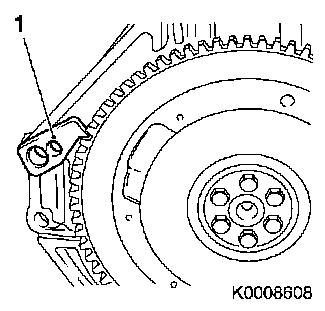

1 Control valve position sensor (potentiometer)

2 Rotary magnet

3 Eccentric pin

4 Screen

|

|

The electric quantity actuator of the

DDE 2.1 injection pump replaces the previously used mechanical speed

regulator. The motion of the rotary magnets is converted into a linear motion

of the control valve by an eccentric.

For this, the quantity actuator is supplied with an actuator

current with variable pulse with from the control unit.

- Engine speed regulation:

After starting (pedal position sensor in idle position), the

idle speed regulation goes into operation

when a certain engine speed limit is exceeded. This is

calculated by the control unit depending on the coolant temperature and thus is

kept to a constant value. The idle speed can be regulated using TECH 1.

The engine maximum speed limitation is performed by the

control unit by reducing the injection quantity.

- Idle stabilizer:

Engine speed stabilization at idle speed is performed by the

idle stabilizer. lt counteracts the rotary irregularities of individual

cylinders caused by deviations in fuel injection quantities. This problem is

remedied by regulated injection quantity correction.

- Judder dampening:

When the accelerator pedal position is changed spontaneously

or there is a sudden change in the road resistance, vibrations arise which, in

conjunction with the regulation frequency of the injection hydraulics, can lead

to juddering.

The engine speed signals send information from segmental

evaluation of the rotational angle at input speed, which is used in the

quantity actuator to counteract rotational irregularities. Judder dampening is

only active during operation; the speed signal must be present.

- Smoke limitation:

At high ambient air temperatures or at low atmospheric

density, the full load amount is reduced to limit smoke emissions.

- Overheating protection:

If the permitted coolant temperature is exceeded when

travelling at high speeds or in mountainous regions, the full load quantity is

reduced (engine protection).

- Exhaust gas recirculation (EGR system):

The return of a proportion of the exhaust gas in the partial

load range lowers the combustion temperature, which reduces the formation of

nitrogen oxides.

There is a more detailed description in section 12;

"Fuel System - Exhaust System".

- Quantity reduction for automatic transmissions:

When downshifting, the quantity is reduced to avoid jerking.

- Cruise control (option):

The desired driving conditions - accelerate, decelerate,

resume speed - can be set or called up via the controls (control lever).

These functions are enabled at speeds above

> 30 km / h (18.5 mph).

- Self - diagnosis:

The task of the self - diagnosis is to recognize faults

to the DDE 2.1, to access replacement values and emergency programs and

subsequently store the fault, and to allow readout via TECH 1.

In addition, trouble - shooting can be facilitated by

calling up current inputs and outputs from the DDE 2.1 control unit.

The DDE 2,1 is checked with TECH 1 in

conjunction with the "Checking Procedures".