Golf Mk1

|

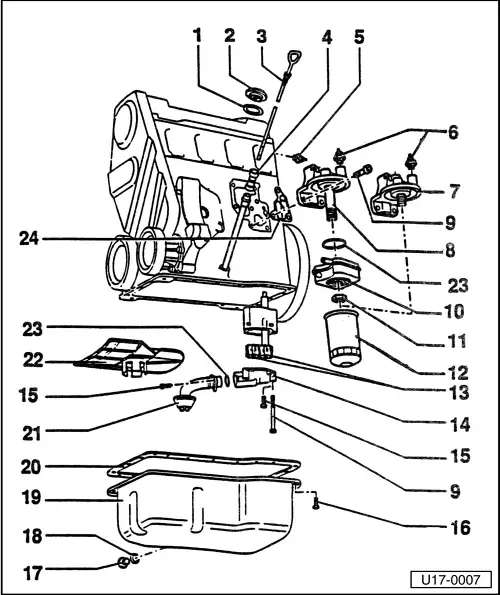

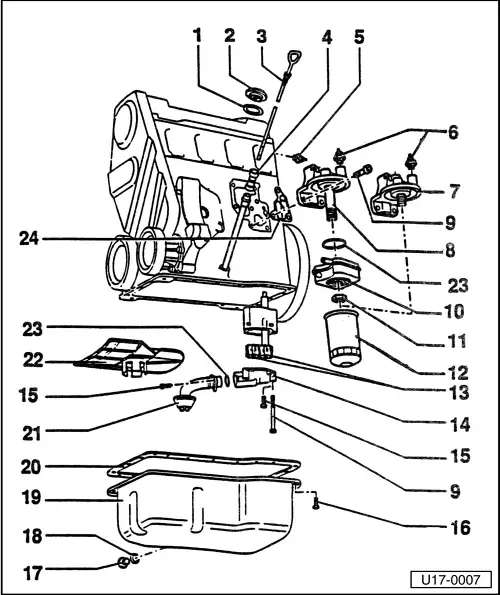

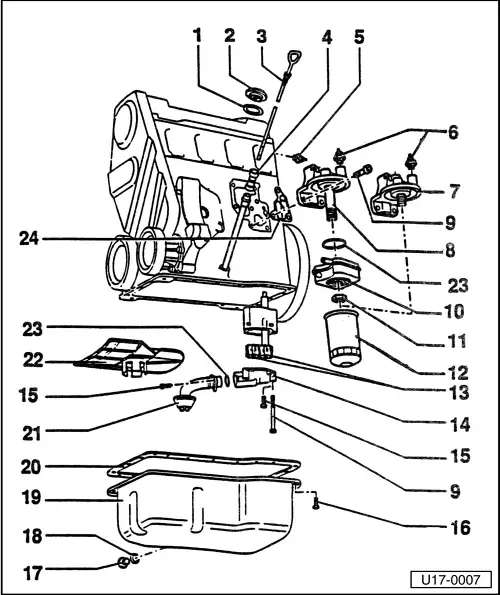

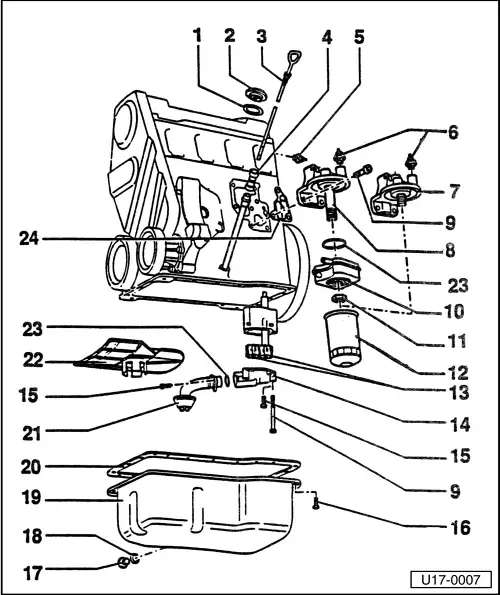

Removing and installing parts of lubrication system

Removing and installing parts of lubrication system

Notes:

Oil system capacity: without oil filter 3,5 ltr. with oil filter 4.0 ltr. Engine oil specifications: Use engine oil to VW standard 501 00 or 502 00. The 502 00 is a higher performance oil with better lubricity at high temperatures. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

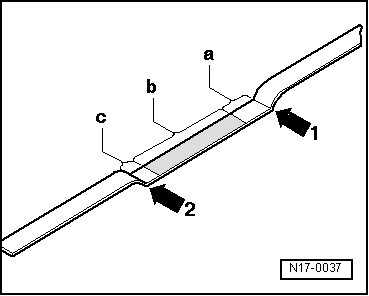

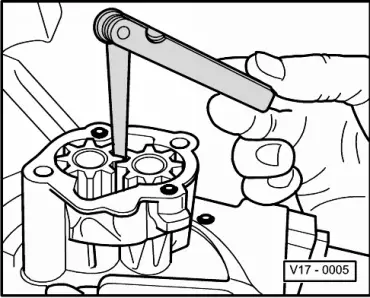

→ Fig.1 Checking oil pump backlash

|

|

|

|

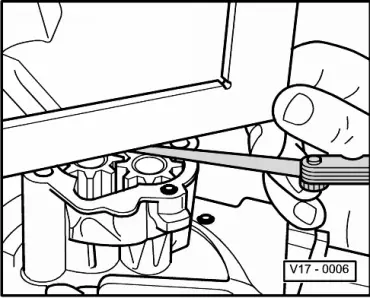

→ Fig.2 Checking oil pump axial clearance

|