Golf Mk4

|

|

|

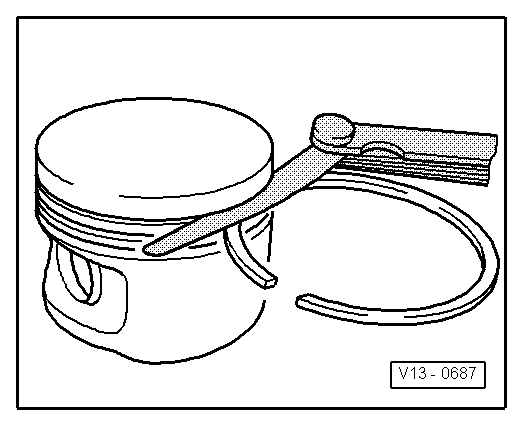

| Piston ring | Gap | ||

| new | Wear limit | ||

| Compression rings | mm | 0.20...0.40 | 0.8 |

| Oil scraper ring | mm | 0.25...0.50 | 0.8 |

|

|

| Piston ring | Ring-to-groove clearance | ||

| new | Wear limit | ||

| Compression rings | mm | 0.06...0.09 | 0.20 |

| Oil scraper ring | mm | 0.03...0.06 | 0.15 |

Note

Note

|

|