Golf Mk4

|

Removing and installing cylinder head

Removing, installing and tensioning toothed belts

|

|

|

|

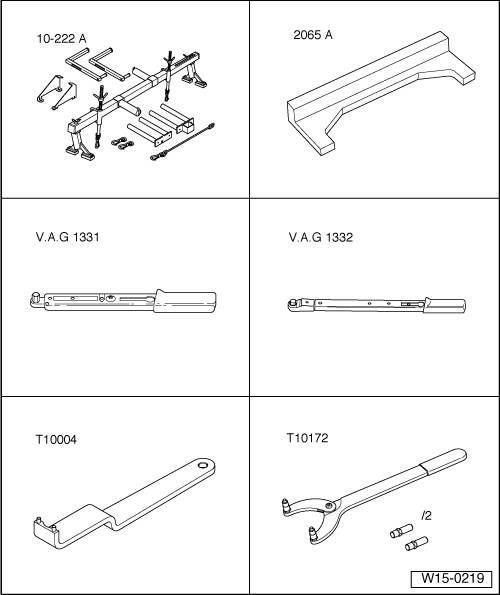

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

Notes: If you only have to take the toothed belt off the camshaft sprocket, e.g. when removing the camshaft or the cylinder head, the following must be considered:

|

|

|

|

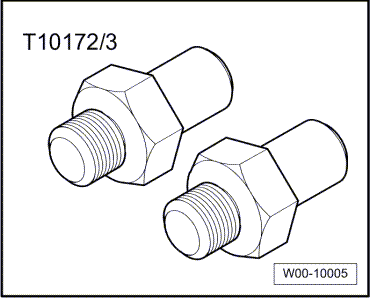

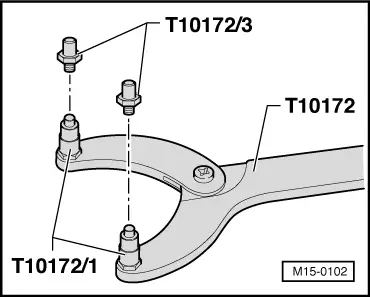

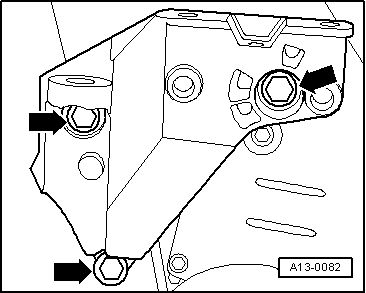

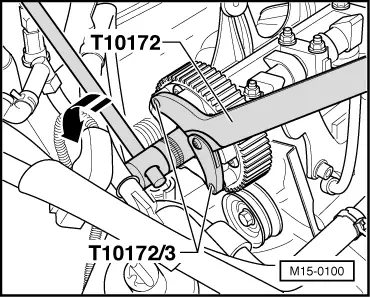

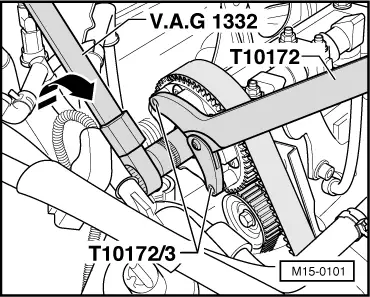

Retrofit counter-bracket T10172

Removing

|

|

|

|

|

|

Notes:

|

|

|

|

|

|

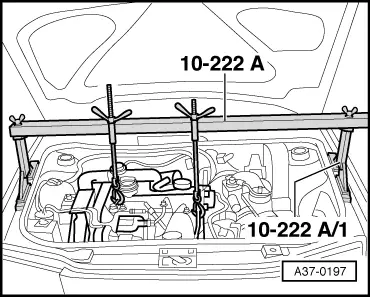

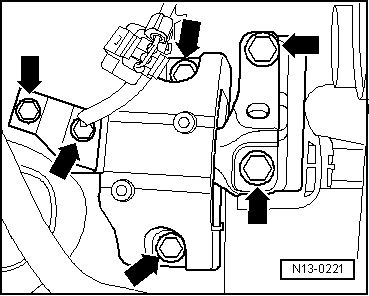

Note: When loosening the front engine mounting bolt the engine must be raised slightly with the support device.

|

|

|

|

|

|

Notes:

|

|

|

|

|

|

Note: |

|

|

|

If the crankshaft is positioned after TDC No. 1 cylinder turn the crankshaft again a bit against the engine direction of rotation and set to TDC No. 1 cylinder.

|

|

|

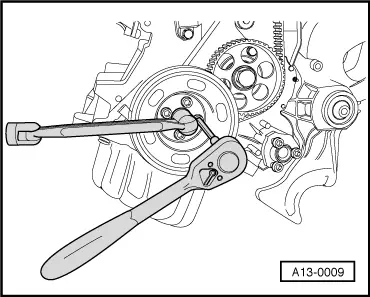

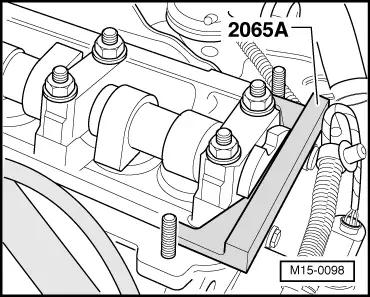

Note: If the crankshaft has been turned to far, turn the crankshaft 1/4 turn back and set the camshaft to TDC No. 1 cylinder again (insert the adjustment bar 2065 A into the camshaft). |

|

|

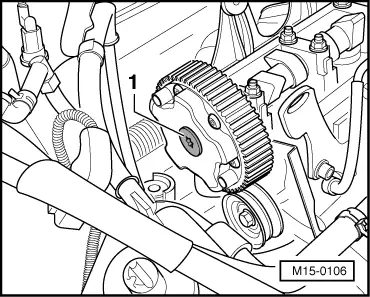

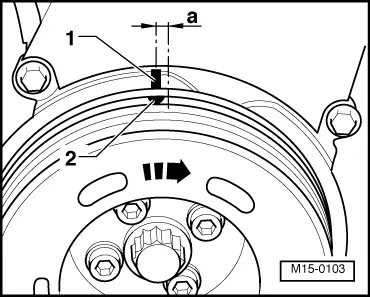

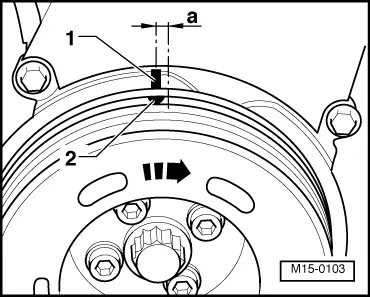

The notch -2- on the vibration damper/belt pulley must be positioned -a- max. 5 mm after the TDC marking -1- on the toothed belt guard lower part. If the crankshaft is not in this area:

|

|

|

|

If the crankshaft is in this area:

Continuation, install toothed belt complete |

|

|

Notes:

Tightening torques for assembly mounting .

|