Golf Mk4

|

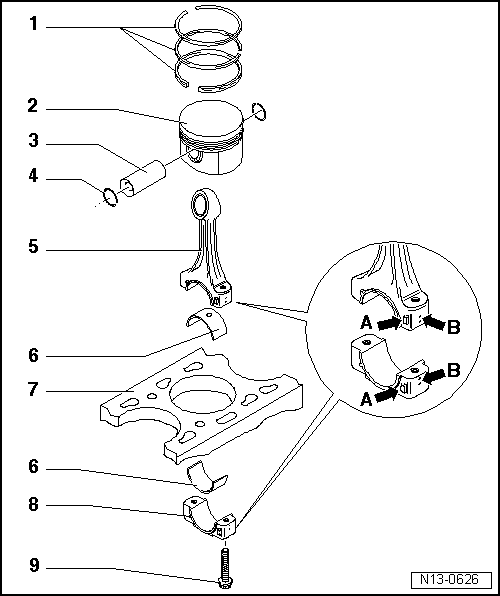

Dismantling and assembling piston and conrod

Dismantling and assembling piston and conrod

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

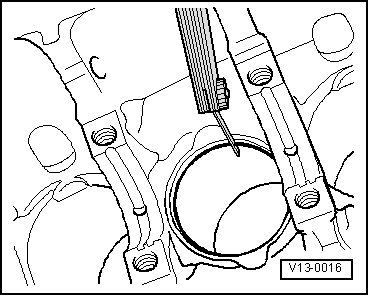

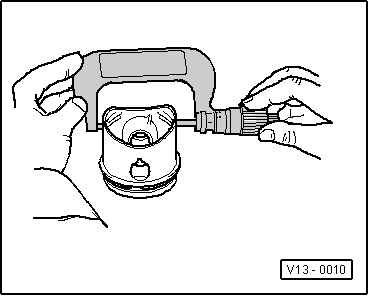

→ Fig. 2 Checking ring to groove clearance Special tools, testers, measuring instruments and auxiliary items required

Test sequence Clean groove before checking.

| |||||||||||||||||

|

|

|

→ Fig. 3 Checking piston Special tools, testers, measuring instruments and auxiliary items required

Test sequence Measure pistons approx. 10 mm from the lower edge of skirt, 90 ° offset to the axis of the piston pin. Deviation from nominal dimension |

|

|

|

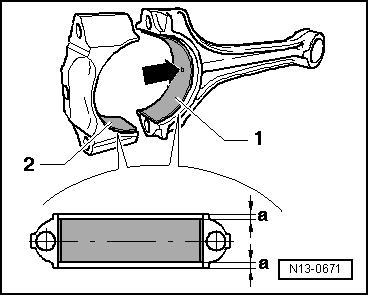

→ Fig. 4 Installation position of bearing shells Bearing shell-1- with oil channel-arrow- for conrod. Bearing shell-2- without oil channel conrod bearing cap.

The dimension -a- must be the same on both the left and the right side. |

|

|

|

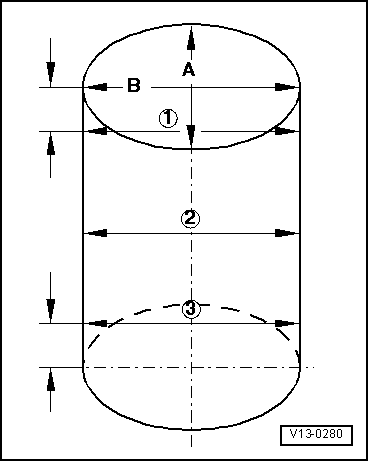

→ Fig. 5 Checking cylinder bores Special tools, testers, measuring instruments and auxiliary items required

Note: Measuring the cylinder bores must not be done when the cylinder block is mounted on a repair stand with adapter bracket VW 540, as incorrect measurements would then be possible. |