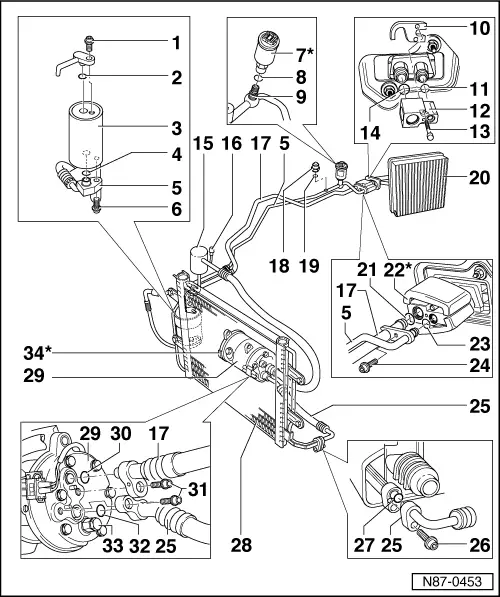

Golf Mk4

| Repairing refrigerant circuit components |

Note

Note| t | The refrigerant must be extracted beforehand, e.g. with air conditioning service station -VAS 6007A-. |

| t | The previously used service stations can still be used ⇒ Volkswagen Workshop Equipment catalogue. |

| t | Safety measures when working on an evacuated refrigerant circuit → Chapter. |

| t | Only the components marked with an “*” can be replaced without opening and evacuating. |

| t | All of the refrigerant circuit's components that have been opened must be sealed with suitable plugs to prevent the ingress of moisture. |

| t | The colour coding of O-rings for R134a refrigerant circuits has been discontinued. Coloured and black O-rings are used. |

| t | Moisten threaded connections of refrigerant circuit with polyethylene glycol (PEG) VW part number 294440 before installation. |

| t | Under certain conditions, it is no longer necessary to renew the receiver each time the refrigerant circuit is opened → Rep. Gr.00Technical information “Air conditioning systems - with refrigerant R134a VW” Renewing parts. |

| 1 - | Bolt |

| q | 15 Nm. |

| 2 - | O-ring |

| q | 10.8 mm; 1.8 mm. |

| 3 - | Receiver with dryer bag |

| q | Functions → Chapter. |

| 4 - | O-ring |

| q | 10.8 mm; 1.8 mm. |

| 5 - | Refrigerant line |

| q | From receiver with dryer bag to expansion valve. |

| 6 - | Bolt |

| q | 15 Nm. |

| 7 - | Air conditioning system pressure switch -F129-* or high pressure sender -G65-* |

| Removing and installing: |

| q | Torque setting 8 Nm |

| q | Renew O-ring (note part number). |

| q | Air conditioning system pressure switch -F129- and high pressure sender -G65- can be removed without having to evacuate refrigerant from refrigerant circuit. |

| q | The high pressure sensor -G65- cannot be checked via the Climatronic self-diagnosis, but only via the engine control unit. |

| q | Checking: vehicle diagnosis, testing and information system -VAS 5051B- in guided fault finding. |

| q | The high pressure sensor -G65- supplies information to radiator fan control unit -J293- and engine control unit. |

| q | Check air conditioning system pressure switch -F129- → Chapter. |

| q | Check high pressure sender -G65- → Chapter. |

| Function: |

| q | Switches radiator fan -V7- to next higher speed when pressure increases in refrigerant circuit. |

| q | Switches off the air conditioner when the pressure is high (for example, insufficient engine cooling). |

| q | Switches off the air conditioner when the pressure is too low (for example, loss of refrigerant). |

| 8 - | O-ring |

| q | 10.8 mm; 1.8 mm. |

| 9 - | Schrader valve |

| 10 - | Threaded plate |

| 11 - | O-ring |

| q | 10.8 mm; 1.8 mm. |

| 12 - | Expansion valve |

| q | In engine compartment on right. |

| q | Aperture must be sealed against splashed water. |

| q | Removing → Chapter. |

| Function |

| t | The expansion valve atomises incoming refrigerant and regulates the flow so that, depending on the heat transport, the vapour does not become a gas until it reaches the outlet of the evaporator. |

| t | The expansion valves for R134a refrigerant circuits are marked with a green sticker. |

| 13 - | Bolts |

| q | 8 Nm. |

| 14 - | O-ring |

| q | 14 mm; 1.8 mm. |

| 15 - | Damper |

| q | In refrigerant hose from expansion valve to air conditioner compressor. |

| q | For vehicles with the engine code BDE near the expansion valve. |

| 16 - | Extraction and charging valve |

| q | Low pressure side. |

| q | Releasing refrigerant into the environment is a punishable offence. |

| q | Removing and installing → Chapter. |

| q | Capacities → Chapter. |

| 17 - | Refrigerant hose |

| q | From expansion valve to air conditioner compressor. |

| q | With damper. |

| 18 - | Extraction and charging valve |

| q | High pressure side. |

| q | Releasing refrigerant into the environment is a punishable offence. |

| q | Removing and installing → Chapter. |

| q | Capacities → Chapter. |

| 19 - | O-ring |

| q | 10.8 mm; 1.8 mm. |

| 20 - | Evaporator |

| q | In passenger compartment. |

| q | Removal → Chapter, Dismantling and assembling evaporator housing. |

| 21 - | O-ring |

| q | 16.7 mm; 1.8 mm. |

| 22 - | Heat insulation* |

| 23 - | O-ring |

| q | 7.6 mm; 1.8 mm. |

| 24 - | Bolt |

| q | 8 Nm. |

| 25 - | Refrigerant hose |

| q | From air conditioner compressor to condenser. |

| 26 - | Bolt |

| q | 15 Nm. |

| 27 - | O-ring |

| q | 10.8 mm; 1.8 mm. |

| 28 - | Condenser |

| q | Removing → Chapter. |

| 29 - | Air conditioner compressor |

| q | With air conditioning system magnetic coupling -N25-. |

| q | Repairing air conditioning system magnetic coupling -N25- → Chapter. |

| q | An air conditioner compressor with no air conditioning system magnetic coupling -N25- is installed in vehicles with engine code BAD. Notes → Chapter. |

| 30 - | O-ring |

| q | 14.3 mm; 2.4 mm. |

| 31 - | Bolts |

| q | 20 Nm. |

| 32 - | O-ring |

| q | 10.8 mm; 1.8 mm. |

| 33 - | High-pressure safety valve |

| q | Checking → Chapter. |

| 34 - | Air conditioning system magnetic coupling -N25- |

| Manufacturer Sanden: |

| q | Repairing air conditioning system magnetic coupling -N25- → Chapter. |

| Manufacturer Zexel: |

| q | Repairing air conditioning system magnetic coupling -N25- → Chapter. |