Golf Mk4

| Adjusting differential |

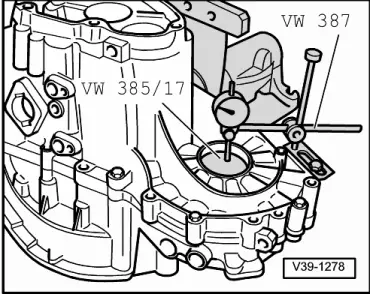

| Special tools and workshop equipment required |

| t | End dimension plate -VW 385/17- |

| t | Universal dial gauge bracket -VW 387- |

| t | Thrust piece -VW 473- |

| t | Thrust plate -30 - 205- |

| t | Torque wrench -V.A.G 1331- |

| t | Dial gauge |

Note

Note

|

Note

Note

|

|

| Measured value | 0.70 mm |

| + Preload (constant) | 0.40 mm |

| Thickness of shim = | 1.10 mm |

|

| Thickness (mm) | Part number |

| 0,65 0,70 0,75 | 02A 409 210 02A 409 210 A 02A 409 210 B |

| 0,80 0,85 0,90 | 02A 409 210 C 02A 409 210 D 02A 409 210 E |

| 0,95 1,00 1,05 | 02A 409 210 F 02A 409 210 G 02A 409 210 H |

| 1,10 1,15 1,20 | 02A 409 210 J 02A 409 210 K 02A 409 210 L |

| 1,25 | 02A 409 210 M |

|