Golf Mk4

| Dismantling and assembling selector forks |

| Special tools and workshop equipment required |

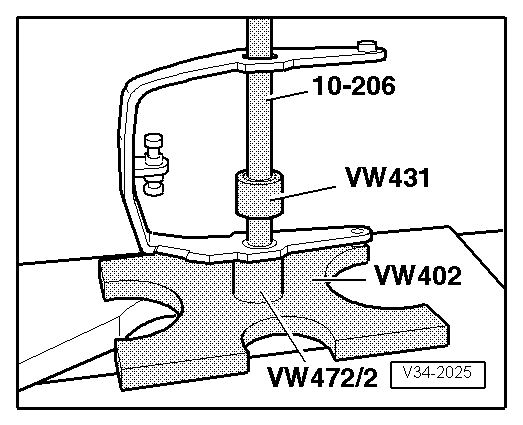

| t | Pressure plate -VW 402- |

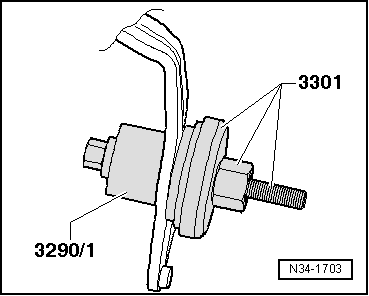

| t | Thrust piece -3290/1- from assembly tool -3290- |

| t | Assembly tool -3301- |

| t | Thrust piece -VW 431- |

| t | Spacer sleeve -VW 472/2- |

| t | Drift -10 - 206- |

|

|

|

|

|

|

Note

Note

|

|

| 1 - | 5th gear selector segment |

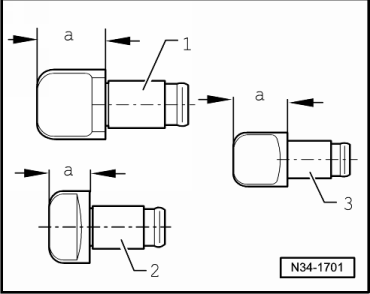

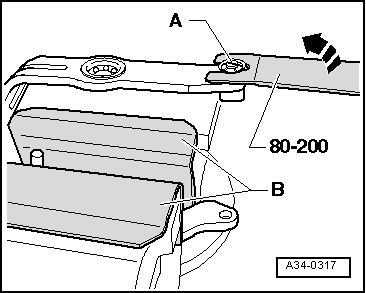

| q | Identification → Fig. |

| q | After lock washer is installed, selector segment must still rotate freely. |

| 2 - | Lock washer |

| q | Always renew |

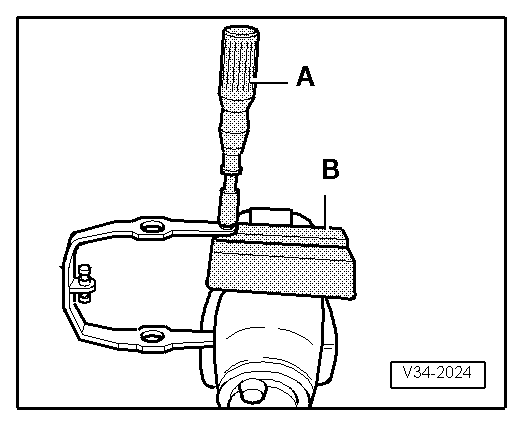

| q | Removing → Fig. |

| q | Installing → Fig. |

| 3 - | 5th gear selector fork |

| q | Adjusting → Anchor |

| 4 - | Bolt, 25 Nm |

| 5 - | 5th gear selector jaw |

| 6 - | Angular contact ball bearing |

| q | Qty. 4 |

| q | Removing → Fig. |

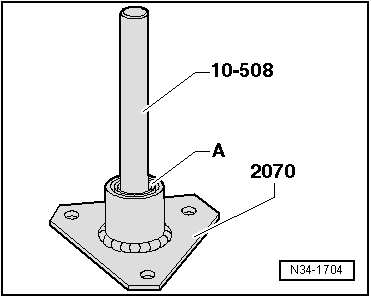

| q | Press inner race into outer race → Fig. |

| q | Installing → Fig. |

| 7 - | Selector fork group with selector plate |

| 8 - | 1st/2nd gear selector segment |

| q | Identification → Fig. |

| q | After lock washer is installed, segment must still rotate freely |

| 9 - | Selector segment for 3rd and 4th gear |

| q | Identification → Fig. |

| q | After lock washer is installed, segment must still rotate freely |

| 10 - | Sliding piece |

| 11 - | Spring |

| 12 - | Selector fork for reverse gear |

| 13 - | Support for reverse gear selector fork |

| 14 - | Retaining ring |

| 15 - |

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

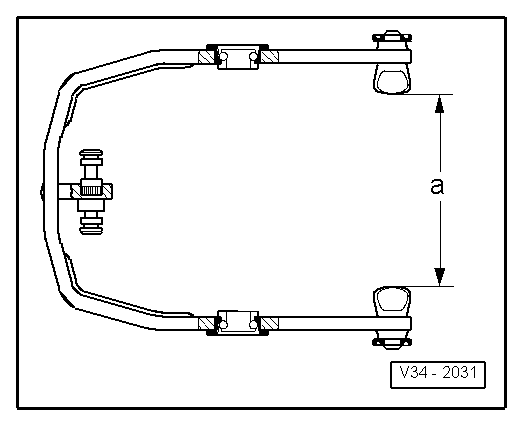

| Dim. -a- (mm) | |

| 1st/2nd gear selector fork | 87,2 ... 87,9 |

| 1st/2nd gear selector forks in conjunction with modified synchronisation | 88,4 ... 89,1 |

| 3rd/4th gear selector fork | 96,0 ... 96,7 |

|