Golf Mk4

| Removing |

|

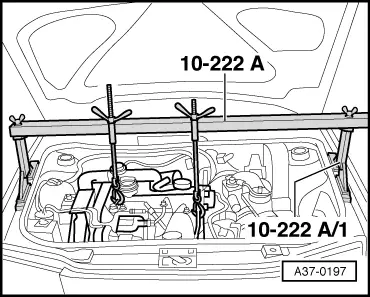

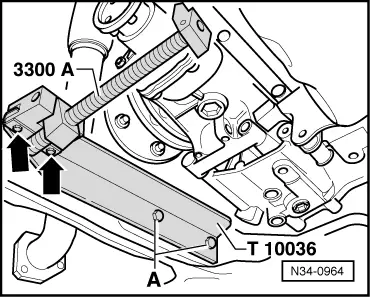

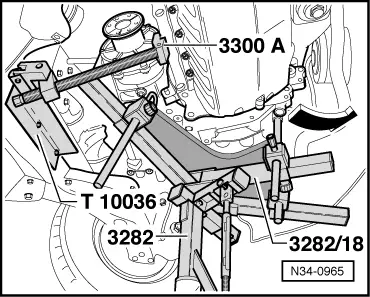

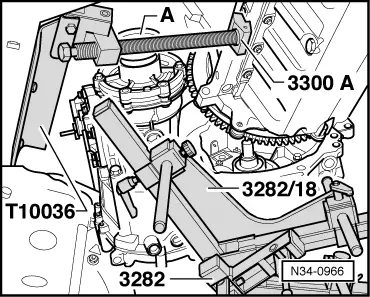

| t | Engine support -3300 A- |

| t | Support rail -T10036- |

| t | Gearbox mounting support -3336- |

| t | Torque wrench -V.A.G 1332- |

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|