Golf Mk4

|

|

|

|

|

|

|

|

|

|

|

|

|

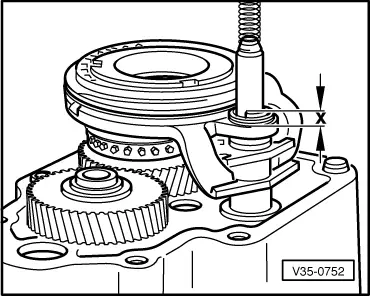

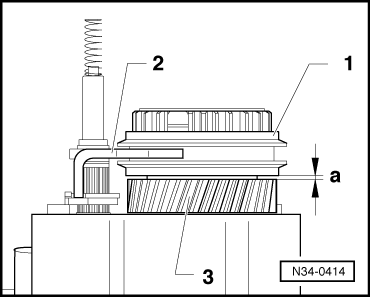

| Thickness (mm) | Identification |

| 2.5 | Brown |

| 2.6 | Black |

| 2.7 | Polished |

| 2.8 | Copper |

| 2.9 | Brass |

| 3.0 | Blue |

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|