Golf Mk4

| Dismantling and assembling output shaft |

| Special tools and workshop equipment required |

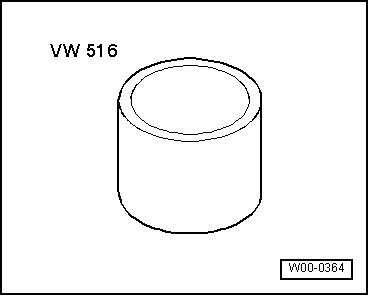

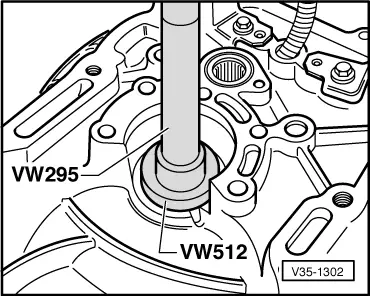

| t | Drift -VW 295- |

| t | Thrust pad -VW 512- |

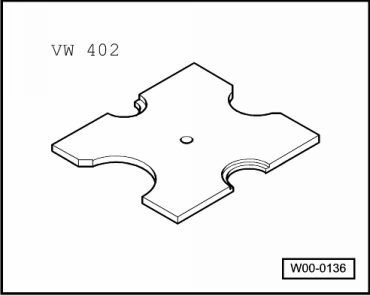

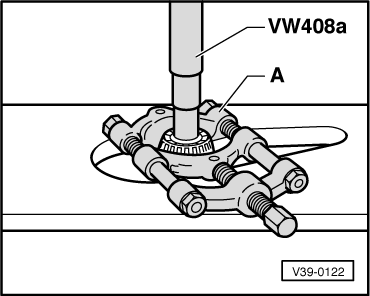

| t | Press tool -VW 408 A- |

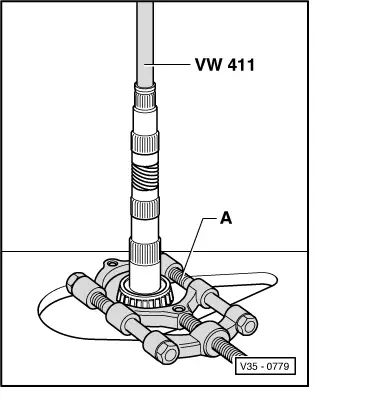

| t | Press tool -VW 411- |

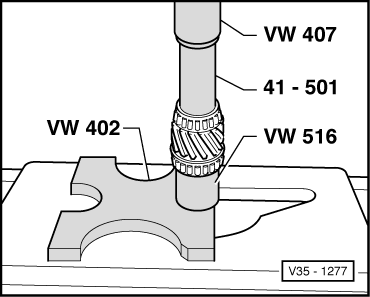

| t | Press tool -VW 407- |

| t | Drift sleeve -41 - 501- |

|

|

|

|

|

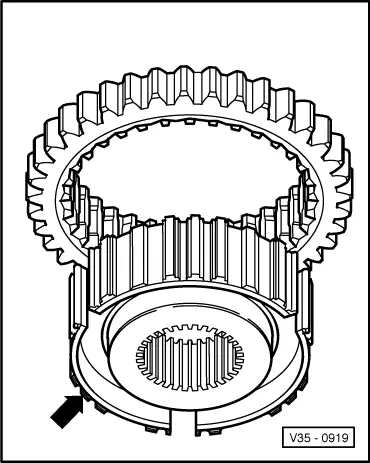

|

Note

Note| t | When installing new gear wheels or a new output shaft, consult technical data → Chapter. |

| t | If output shaft or tapered roller bearings have been renewed, adjust output shaft → Chapter. |

| 1 - | Gearbox housing cover |

| 2 - | Retaining ring for gear wheel for 5th gear |

| q | Renew. |

| 3 - | Thrust washer |

| 4 - | Gear wheel for 5th gear |

| q | Installing → Chapter |

| 5 - | Gearbox housing |

| 6 - | Needle bearing |

| q | Removing and installing → Fig. |

| 7 - | Retaining ring for gear wheel for 4th gear |

| q | Renew. |

| 8 - | Gear wheel for 4th gear |

| 9 - | Retaining ring for gear wheel for 3rd gear |

| q | Renew. |

| q | Redetermining thickness → Chapter |

| 10 - | Gear wheel for 3rd gear |

| q | Installation position → Chapter |

| q | Adjusting axial play → Chapter. |

| 11 - | 2nd gear synchromeshed gear |

| 12 - | Needle bearing for 2nd gear synchromeshed gear |

| q | Pulling off inner race → Chapter. |

| q | Pressing on inner race → Chapter. |

| 13 - | Synchro-ring for 2nd gear |

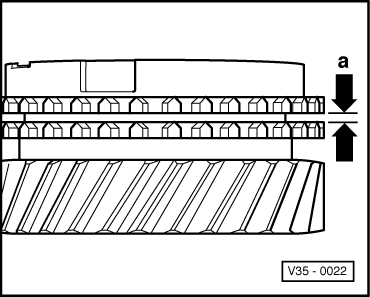

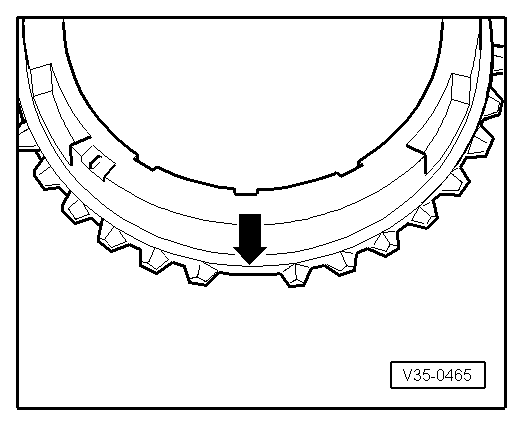

| q | Check for wear → Fig. |

| 14 - | Locking collar with synchro-hub for 1st and 2nd gears |

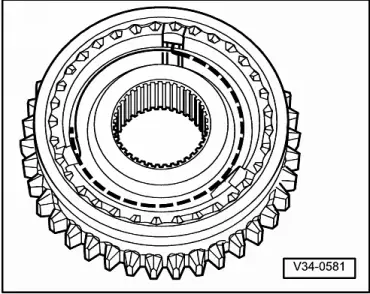

| q | Assembling locking collar and synchro-hub → Fig. and → Fig. |

| q | Removing and installing → Chapter |

| 15 - | Synchro-ring for 1st gear |

| q | Check for wear → Fig. |

| q | Identification → Fig. |

| 16 - | Synchromeshed gear for 1st gear |

| 17 - | Spring |

| 18 - | Locking collar |

| 19 - | Synchro-hub |

| 20 - | Locking pieces (Qty. 3) |

| 21 - | Needle bearing |

| q | For 1st gear |

| 22 - | Thrust washer |

| q | Installation position → Chapter |

| 23 - | Clutch housing |

| 24 - | Shim |

| q | For output shaft |

| q | Adjustment overview → Chapter |

| 25 - | Small tapered roller bearing outer race |

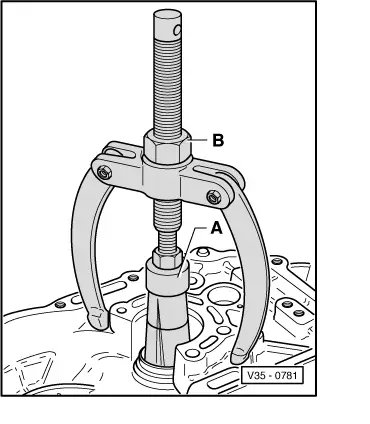

| q | Pulling out → Fig. |

| q | Pressing in → Fig.. |

| 26 - | Small tapered roller bearing inner race |

| q | Pressing off → Fig.. |

| q | Pressing on → Fig. |

| 27 - | Output shaft |

| q | Paired with final drive gear wheel. Always renew as a set. |

| q | Adjusting → Chapter |

| 28 - | Large tapered roller bearing inner race |

| q | Pressing off → Fig.. |

| q | Pressing on → Fig. |

| 29 - | Bearing support |

| q | With large tapered roller bearing outer race and stop for reverse gear wheel. |

| q | Change outer race only together with large tapered roller bearing and bearing support |

| 30 - | Hexagon bolt, 25 Nm and turn 90° further |

|

|

| Gap -a- | Installation (new) dimension | Wear limit |

| 1st and 2nd gears | 1.1…1.7 mm | 0.5 mm |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|