Golf Mk4

|

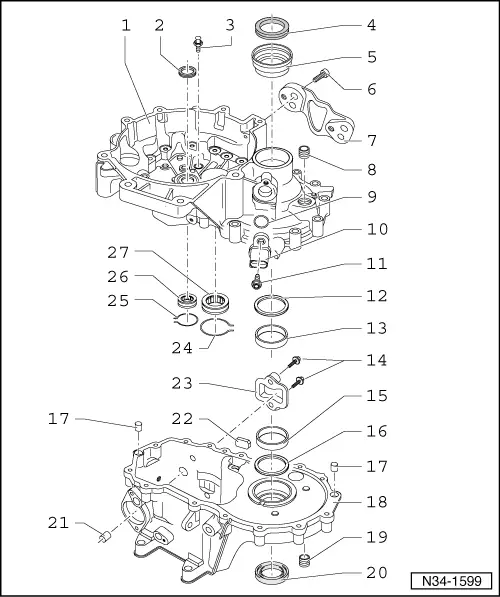

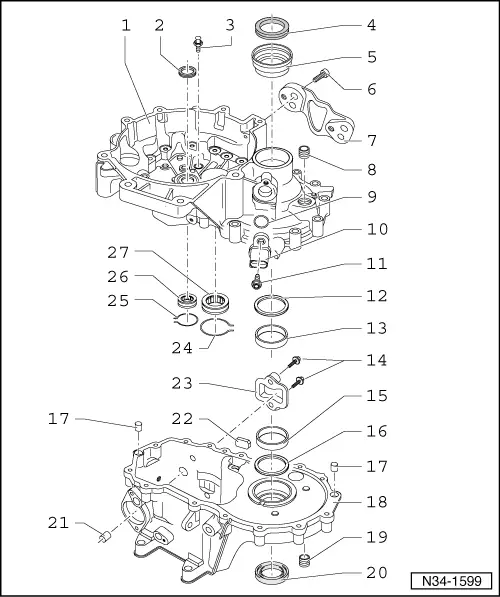

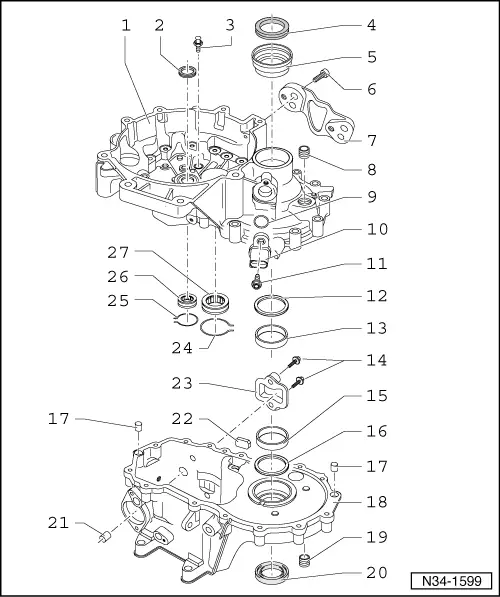

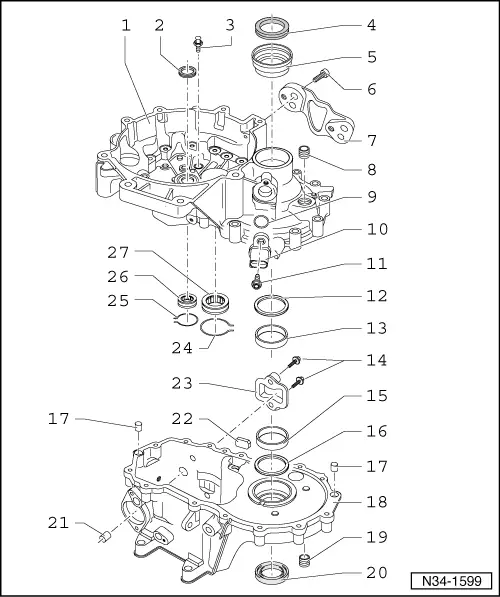

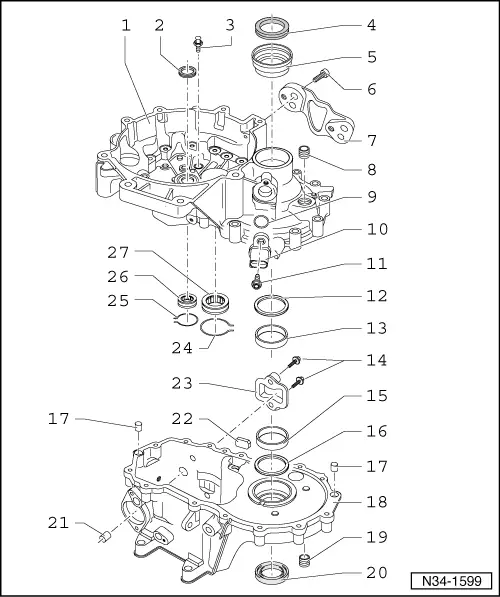

Servicing gearbox housing and clutch housing

Servicing gearbox housing and clutch housing

|

|

|

|

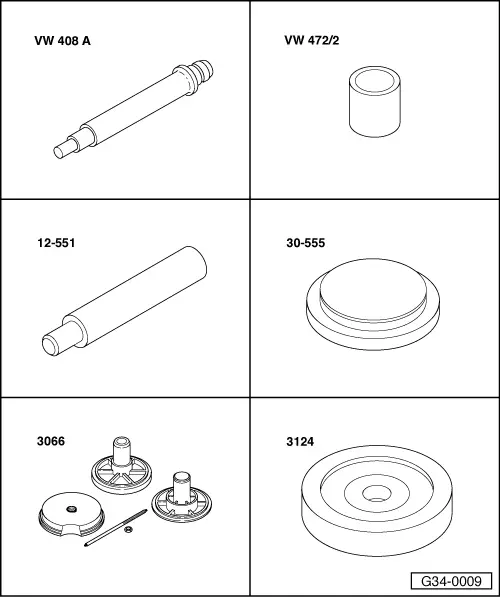

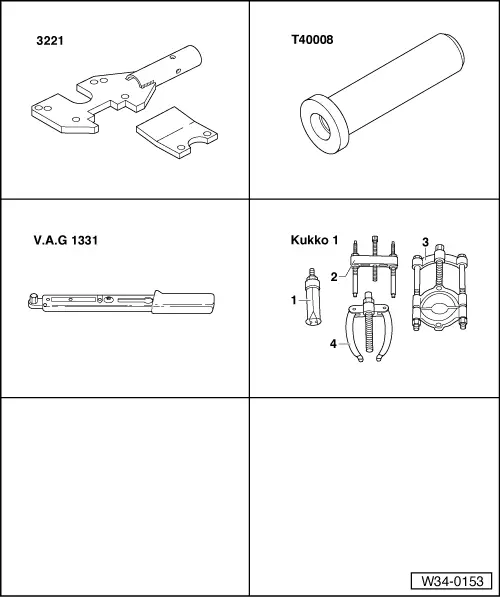

Special tools, workshop equipment, test and measuring appliances and auxiliary items required

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

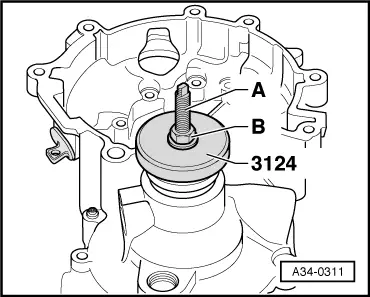

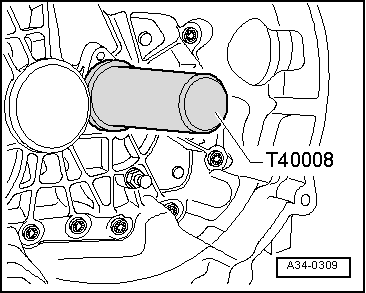

→ Fig.1 Driving in input shaft oil seal flush |

|

|

|

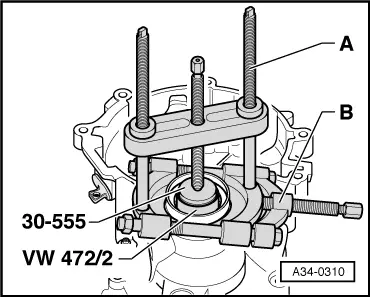

→ Fig.2 Pulling out oil seal sleeve

A - Puller, e.g. Kukko 18/1 B - Separating device 12...75 mm, e.g. Kukko 17/1 |

|

|

|

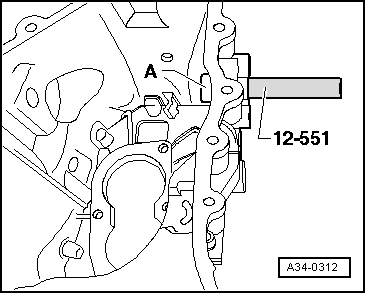

→ Fig.4 Driving out selector shaft sleeve -A- |

|

|

|

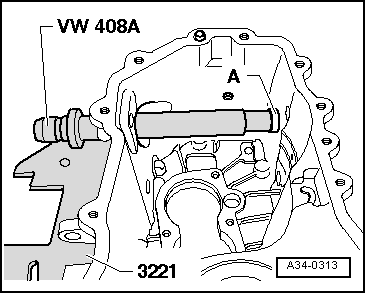

→ Fig.5 Driving in selector shaft sleeve -A- |