|

General repair instructions

General repair instructions

The maximum possible care and cleanliness and proper tools are essential to ensure satisfactory and successful gearbox repairs. The usual basic safety precautions also, naturally apply when carrying out vehicle repairs.

A number of generally valid instructions applicable for the various repair procedures - which were previously repeated a number of times at numerous places in the Workshop Manual - are summarised here. They apply to this Workshop Manual.

Gearbox

-

◆ When installing ensure that the dowel sleeves between the engine and gearbox are correctly located.

-

◆ When assembling mounting brackets as well as other waxed components the contacts surfaces must be cleaned. Contact surfaces must be free of grease and wax.

-

◆ When changing a gearbox fill with gear oil to the lower edge of the filler hole.

-

◆ Capacities and specifications

.

Gaskets, sealing rings

-

◆ Thoroughly clean joint surfaces and apply sealant AMV 188 200 03.

-

◆ Apply sealant uniformly but not too thick.

-

◆ Renew "O-rings".

-

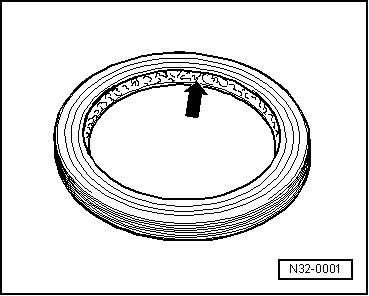

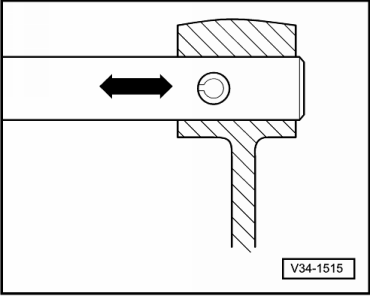

◆ Radial shaft oil seals.

Before installing:

|