Golf Mk4

| Repairing clutch housing, through gearbox date 18 05 3 |

| Special tools and workshop equipment required |

| t | Press tool -VW 407- |

| t | Sleeve -30 - 21- |

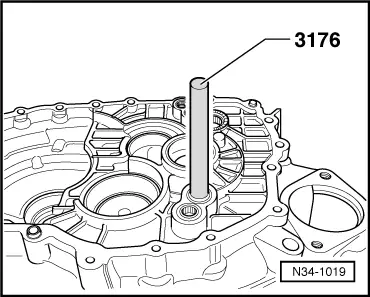

| t | Centring mandrel -3176- |

| t | Thrust piece -T40008- |

| t | Internal puller -1 - Kukko 21/2- |

| t | Internal puller -1 - Kukko 21/4- |

| t | Counter support -4 - Kukko 22/1- |

| t | Counter support -4 - Kukko 22/2- |

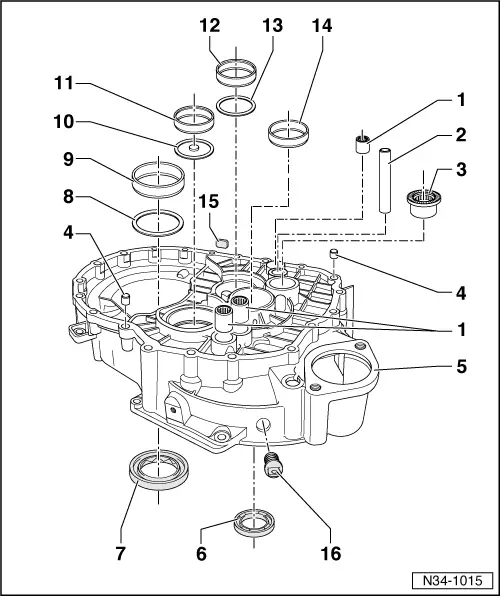

| 1 - | Bearing bush |

| q | For selector rods |

| q | Renew each time after removing |

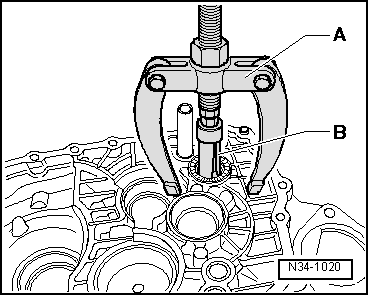

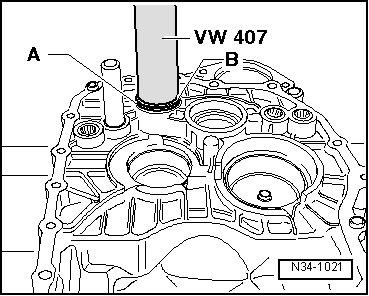

| q | Pulling out → Fig. |

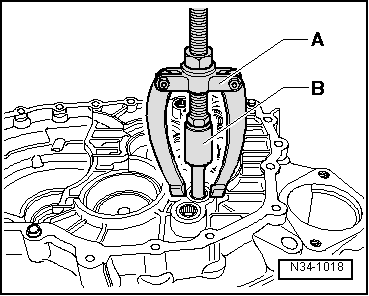

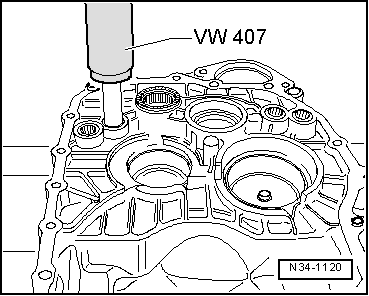

| q | Driving in → Fig. |

| 2 - | Reverse gear selector fork axle |

| q | Axle cannot be removed with workshop tools |

| q | If a new clutch housing is used, a new axle must be pressed in → Fig. |

| 3 - | Needle bearing |

| q | Renew each time after removing |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| 4 - | Dowel sleeve |

| q | Qty. 2 |

| 5 - | Clutch housing |

| q | From gearbox date 06 04 0, with additional hole and recess for locking plate to secure tapered roller bearing outer race for input shaft → Item |

| q | When renewing, ⇒ adjustment overview → Chapter |

| 6 - | Input shaft seal |

| When gearbox is dismantled, oil seal can be removed with sleeve -30-21-. |

| q | Renewing → Item |

| 7 - | Seal |

| q | Renewing → Chapter |

| 8 - | Washer |

| q | For differential |

| q | Always 0.65 mm thick |

| q | Installation position: If there is a shoulder on inner circumference, it must face seal → Item |

| 9 - | Tapered roller bearing outer race |

| q | For differential |

| q | Removing and installing → Chapter |

| q | If renewed, adjust differential → Chapter |

| 10 - | Oil deflector ring |

| q | Installation position: shoulder on hole faces output shaft |

| 11 - | Tapered roller bearing outer race |

| q | For output shaft for 1st through 4th gears |

| q | Removing and installing → Chapter |

| q | If renewed, adjust output shaft for 1st through 4th gears → Chapter |

| 12 - | Tapered roller bearing outer race |

| q | For output shaft for 5th, 6th and reverse gears |

| q | Removing and installing → Chapter |

| q | If renewed, adjust output shaft for 5th, 6th and reverse gears → Chapter |

| 13 - | Washer |

| q | For output shaft |

| q | Always 0.65 mm thick |

| 14 - | Tapered roller bearing outer race |

| q | For input shaft |

| q | Removing and installing → Chapter |

| q | If renewed: adjust input shaft → Chapter |

| q | From gearbox date 06 04 0 secured with locking plate and bolt. |

| q | Bolt, 12 Nm |

| q | Always renew |

| 15 - | Magnet |

| q | Held in place by housing joint surface |

| 16 - | Cap |

| q | Not fitted in all clutch housings |

|

|

|

|

|

|

|

|

Note

Note