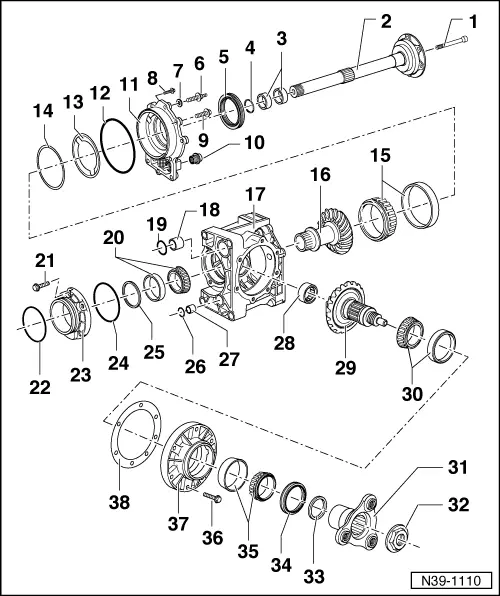

Golf Mk4

|

| 1 - | Countersunk bolt, 25 Nm |

| q | Right flange shaft to threaded piece of differential |

| q | Length of countersunk bolt is matched to bevel box. |

| q | Check part number of bevel box. |

| q | When renewing bevel box, allocate countersunk bolt with → Electronic parts catalogue (ETKA). |

| 2 - | Right flange shaft |

| q | Removing → Anchor |

| q | Pressing in → Fig. |

| q | Removing and installing with gearbox installed → Chapter. |

| 3 - | Needle bearing (polygon bearing) |

| q | Qty. 2 |

| q | Renewing → Chapter |

| 4 - | Retaining ring |

| q | Always renew |

| 5 - | Seal |

| q | Pry out with assembly lever |

| q | Drive in to stop with thrust piece -T10049- → Anchor |

| q | Renewing with gearbox installed → Chapter |

| 6 - | Centre hex stud, 45 Nm |

| q | M10/ M8 |

| 7 - | Washer |

| q | For centre hex stud → Item. |

| 8 - | Bolt, 25 Nm |

| q | M8 |

| 9 - | Bolt, 45 Nm |

| q | M10 |

| 10 - | Oil drain plug, 60 Nm |

| q | With magnet and seal |

| 11 - | Large cover → Remark |

| q | Removing → Anchor |

| q | Do not cant when installing. Tighten securing bolts diagonally and in stages |

| 12 - | O-ring |

| q | Always renew, if part of original equipment |

| 13 - | Oil deflector ring |

| q | Observe installation position → Anchor |

| q | Installed in some gearboxes between shim S1 → Item and large tapered roller bearing for supporting bevel gear with stub shaft → Item. |

| 14 - | Shim S1 |

| q | Note thickness |

| q | Installed in some gearboxes between oil deflector ring → Item and large cover → Item. |

| q | Adjustment overview → Chapter |

| 15 - | Large tapered roller bearing for supporting bevel gear with stub shaft → Remark |

| Inner race: |

| q | Pressing off → Anchor |

| q | Pressing on → Anchor |

| Outer race: |

| q | Pulling out → Anchor |

| q | Pressing in → Anchor |

| 16 - | Bevel gear with stub shaft → Remark |

| q | Paired with shaft bevel gear → Item. |

| q | Cannot be pressed off input shaft. |

| q | Adjusting → Chapter |

| 17 - | Final drive housing → Remark |

| q | Drain oil then and secure bevel box on assembly stand using gearbox support -T10108- → Chapter. |

| 18 - | Sleeve for oil supply |

| q | Pulling out → Anchor |

| q | Pressing in → Fig. |

| 19 - | O-ring |

| q | Always renew |

| 20 - | Small tapered roller bearing for supporting bevel gear with stub shaft → Remark |

| Inner race: |

| q | Sits loosely on input shaft |

| q | Removing → Anchor |

| q | Installing → Anchor |

| Outer race: |

| q | Sits loosely in final drive housing |

| q | Removing → Anchor |

| q | Installing → Anchor |

| 21 - | Bolt, 25 Nm |

| 22 - | O-ring |

| q | Always renew |

| q | Must lie in circumferential groove. |

| 23 - | Small cover → Remark |

| q | Removing → Anchor |

| q | Do not cant when installing. Tighten securing bolts diagonally and in stages |

| 24 - | O-ring |

| q | Always renew |

| 25 - | Shim S2 |

| q | Note thickness |

| q | Adjustment overview → Chapter |

| 26 - | O-ring |

| q | Always renew |

| 27 - | Sleeve for oil supply |

| q | Pulling out → Anchor |

| q | Pressing in → Fig. |

| 28 - | Roller sleeve |

| q | Pulling out → Anchor |

| q | Pressing in → Fig. |

| 29 - | Shaft bevel gear → Remark |

| q | Is paired to bevel gear (with stub shaft) |

| q | Clean thread |

| q | Lubricate splines for output flange with multi-purpose grease. |

| q | Adjusting → Chapter |

| 30 - | Large tapered roller bearing for shaft bevel gear → Remark |

| Inner race: |

| q | Set on shaft bevel gear → Item. |

| Outer race: |

| q | Pressing out → Anchor |

| q | Pressing in → Anchor |

| 31 - | Output flange → Remark |

| q | Pulling out → Anchor |

| q | Pulling in → Fig. |

| q | Lubricate splines with multi-purpose grease. |

| 32 - | Hexagon nut, 475 Nm |

| q | Unscrewing → Anchor |

| q | Fitting → Anchor |

| q | Always renew |

| q | Insert with locking fluid -D 000 600- |

| 33 - | Shim S4 |

| q | Note thickness |

| q | Adjustment overview → Chapter |

| q | Set on shaft bevel gear → Item before inserting small tapered roller bearing inner race → Item. |

| 34 - | Seal |

| q | Replace only with bevel box removed → Chapter |

| 35 - | Small tapered roller bearing for shaft bevel gear → Remark |

| Outer race: |

| q | Pressing out → Anchor |

| q | Pressing in → Anchor |

| Inner race: |

| q | Pull off output flange → Anchor. |

| q | Place in outer race. |

| 36 - | Bolt, 25 Nm |

| q | Insert with sealant -AMV 188 200-. |

| 37 - | Pinion housing → Remark |

| q | Removing → Anchor |

| q | Installing → Anchor |

| q | Do not cant when installing. Tighten securing bolts diagonally and in stages. |

| 38 - | Shim S3 |

| q | Note thickness |

| q | Adjustment overview → Chapter |

| q | Before installing, coat both sides with sealant -AMV 188 200-. |