Golf Mk4

| Dismantling and assembling differential |

| Special tools and workshop equipment required |

| t | Gearbox support -VW 353- |

| t | Pressure plate -VW 401- |

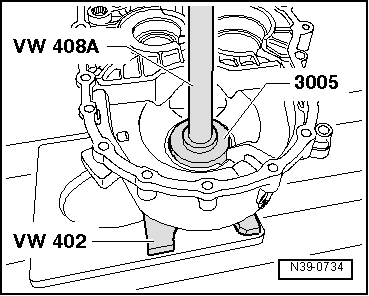

| t | Pressure plate -VW 402- |

| t | Press tool -VW 407- |

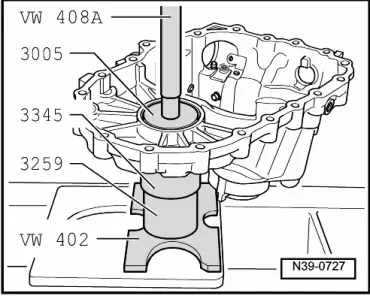

| t | Press tool -VW 408A- |

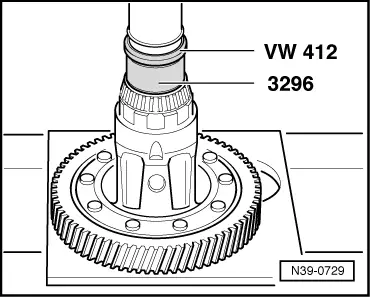

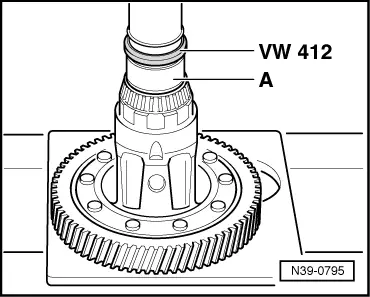

| t | Press tool -VW 412- |

| t | Thrust plate -40-105- |

| t | Thrust plate -3005- |

| t | Tube -3259- |

| t | Tube -3296- |

| t | Wheel bearing tube -3345- |

| t | Torque wrench -V.A.G 1332- |

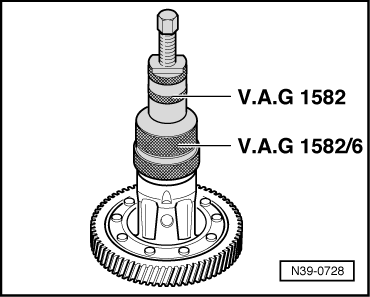

| t | Tapered roller bearing puller -V.A.G 1582- |

| t | Adapter -V.A.G 1582/6- |

| t | Internal puller -1 Kukko 21/7- |

| t | Puller -2 - Kukko 18/1- |

| t | Splitter -3 - Kukko 17/1- |

| t | Counter support -4 - Kukko 22/2 - |

Note

Note

|

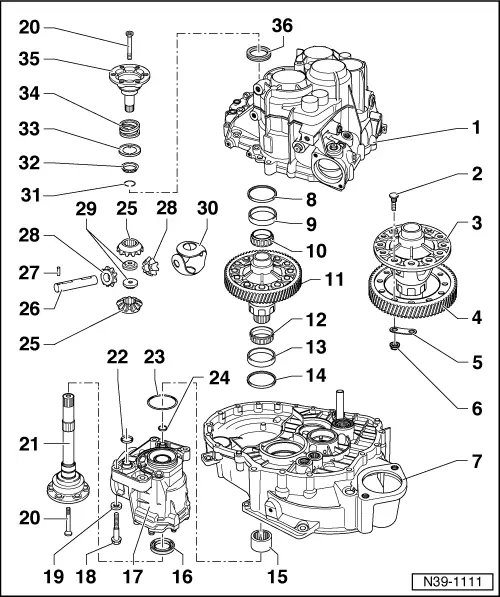

| 1 - | Gearbox housing |

| 2 - | Bolt |

| q | The final drive gear ( → Item) and the differential housing ( → Item) are offered only as an assembly. |

| q | Individual parts → Item, → Item, → Item , → Item and → Item have been discontinued. |

| 3 - | Differential cage |

| q | The final drive gear ( → Item) and the differential housing ( → Item) are offered only as an assembly. |

| q | Individual parts → Item, → Item, → Item , → Item and → Item have been discontinued. |

| 4 - | Final drive gear wheel |

| q | The final drive gear ( → Item) and the differential housing ( → Item) are offered only as an assembly. |

| q | Individual parts → Item, → Item, → Item , → Item and → Item have been discontinued. |

| 5 - | Backing plate |

| q | The final drive gear ( → Item) and the differential housing ( → Item) are offered only as an assembly. |

| q | Individual parts → Item, → Item, → Item , → Item and → Item have been discontinued. |

| 6 - | Nut, 40 Nm and turn 45° further |

| q | Always renew |

| q | The final drive gear ( → Item) and the differential housing ( → Item) are offered only as an assembly. |

| q | Individual parts → Item, → Item, → Item , → Item and → Item have been discontinued. |

| 7 - | Clutch housing |

| 8 - | Shim |

| q | For differential |

| q | Determining thickness → Chapter |

| 9 - | Tapered roller bearing outer race |

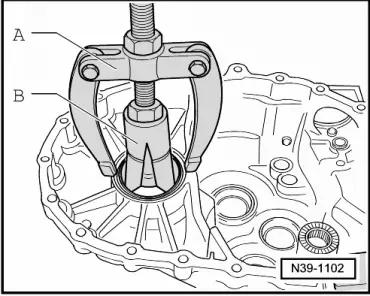

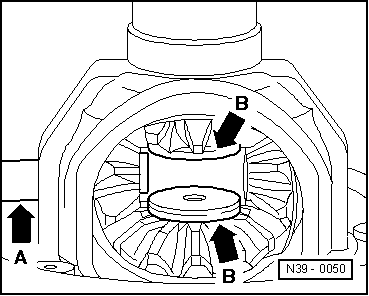

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| 10 - | Tapered roller bearing inner race |

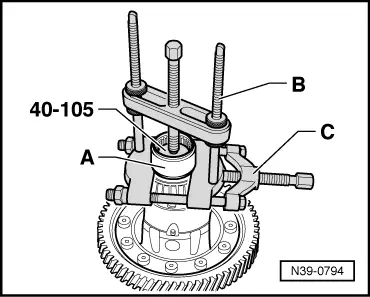

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 11 - | Differential cage |

| 12 - | Tapered roller bearing inner race |

| q | Before removing, pull connecting piece off ( → Item). |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 13 - | Tapered roller bearing outer race |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| 14 - | Washer |

| q | Allocation → Electronic parts catalogue (ETKA) |

| 15 - | Bevel box connecting piece |

| q | Pressed onto differential housing |

| q | Press on and off only with differential housing removed |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 16 - | Seal |

| q | For right flange shaft |

| q | Left and right diameters differ |

| q | Renewing with gearbox installed → Chapter |

| 17 - | Bevel box |

| q | Removing and installing with gearbox installed → Chapter |

| q | Removing and installing with gearbox removed → Anchor |

| 18 - | Hexagon bolt, 40 Nm and turn 45° further |

| q | Always renew |

| 19 - | Washer |

| 20 - | Countersunk bolt, 25 Nm |

| q | Screw into threaded piece ( → Item) |

| 21 - | Right flange shaft |

| 22 - | O-ring |

| q | Always renew |

| 23 - | O-ring |

| q | Always renew |

| 24 - | O-ring |

| q | Always renew |

| 25 - | Sun wheel |

| q | Installing → Fig. |

| q | Allocation → Electronic parts catalogue (ETKA) |

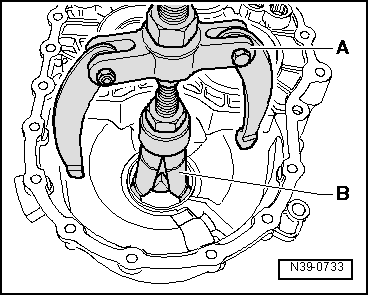

| 26 - | Differential pinion pin |

| q | Drive out using drift |

| q | Installing → Fig. |

| q | Allocation → Electronic parts catalogue (ETKA) |

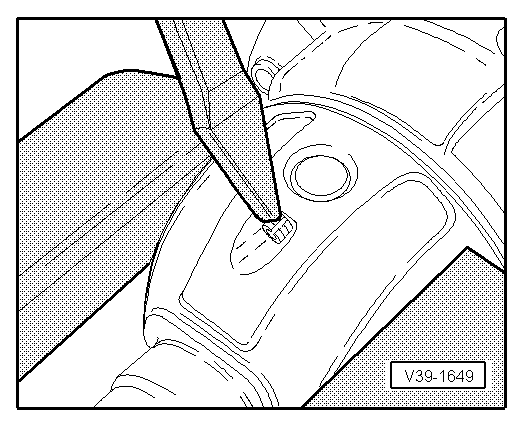

| 27 - | Spring pin |

| q | For securing differential pinion pin |

| q | Allocation → Electronic parts catalogue (ETKA) |

| q | Removing and installing → Fig. |

| 28 - | Planet pinion |

| q | Installing → Fig. |

| q | Allocation → Electronic parts catalogue (ETKA) |

| 29 - | Threaded piece |

| q | Installing → Fig. |

| q | Allocation → Electronic parts catalogue (ETKA) |

| 30 - | One-piece thrust washer |

| q | Coat with gear oil when installing |

| q | Allocation → Electronic parts catalogue (ETKA) |

| 31 - | Retaining ring |

| q | Holds tapered ring, thrust washer and spring in position when flange shaft is removed |

| 32 - | Tapered ring |

| q | With grooves to engage in thrust washer |

| q | Installation position: taper towards differential cage |

| 33 - | Thrust washer |

| q | Installation position: shoulder faces spring, lugs face tapered ring |

| 34 - | Compression spring for flange shaft |

| q | Installed behind flange shafts |

| 35 - | Left flange shaft |

| q | From gearbox date 19 05 3, with protective ring |

| q | Protective ring protects seal from dirt. |

| q | Lever off protective ring using screwdriver on alternate sides. |

| q | Install with indentation facing away from threaded hole in flange shaft |

| q | Push on protective ring to stop by hand |

| q | Protective ring must engage in flange shaft |

| 36 - | Seal |

| q | For left flange shaft |

| q | Left and right diameters differ |

| q | Renewing with gearbox installed → Chapter |

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|