| –

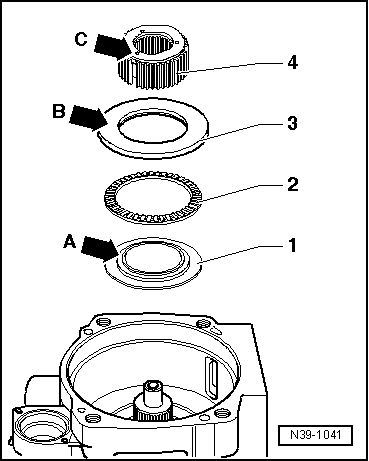

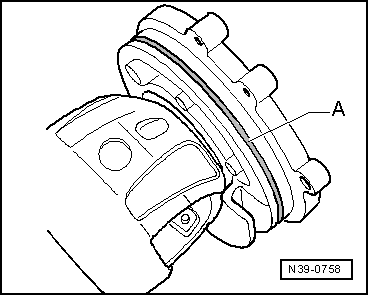

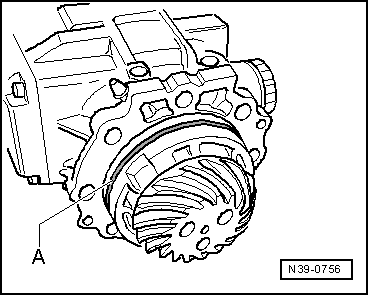

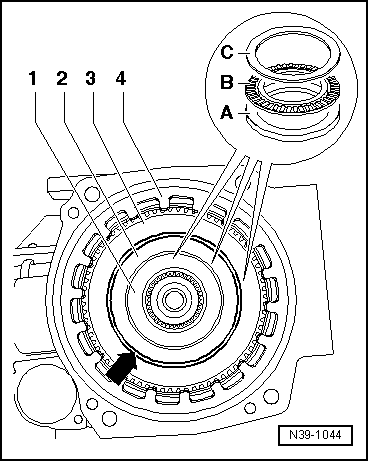

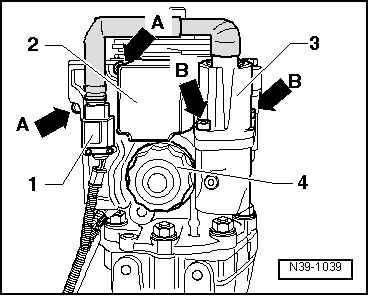

| Lay thicker thrust washer -A- on wheel rollers and rollers in plate housing. |

| –

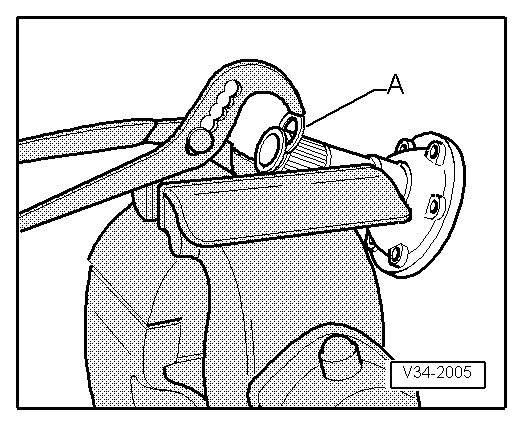

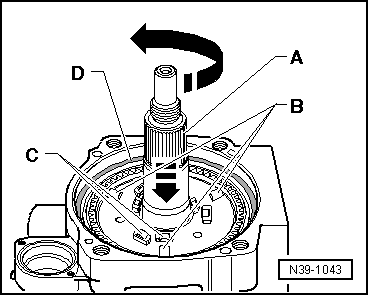

| On top of that, lay needle thrust bearing -B- and thin thrust washer -C- for needle thrust bearing. |

Note | t

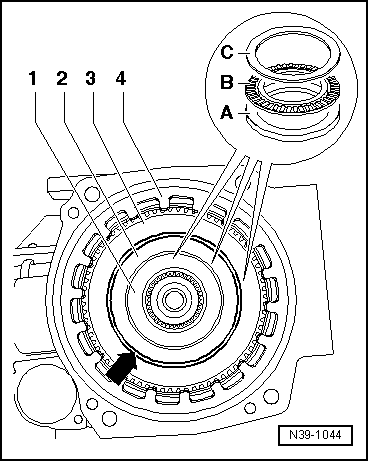

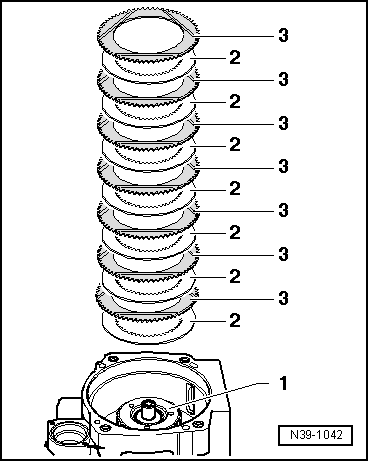

| The individual needle thrust bearing packets 1 through 3 are allocated to the diameters of the pistons in Haldex coupling cover. |

| t

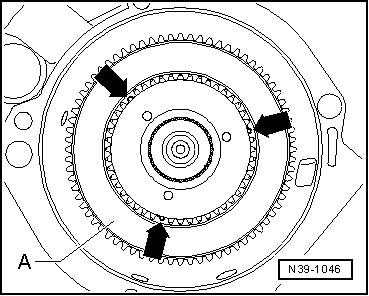

| Ensure that gap -arrow- between needle thrust bearing packets 2 and 3 is of uniform size all around the circumference. |

| –

| Insert dished spring -4- with greater diameter (concave side) facing ring ( → Anchor, fig. N39-1043). |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note