| –

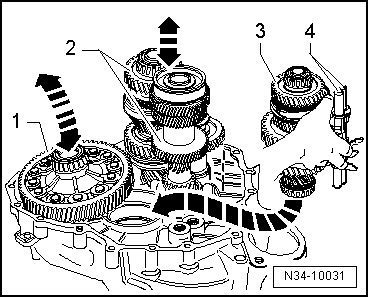

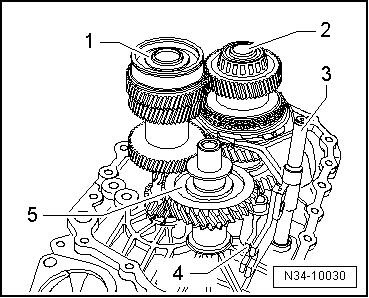

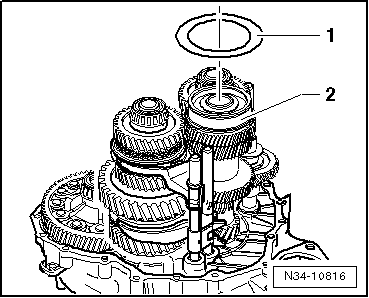

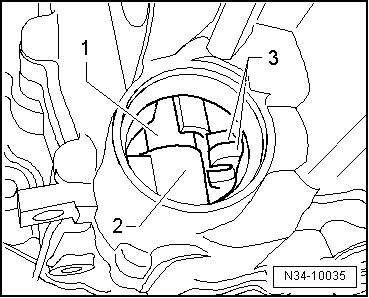

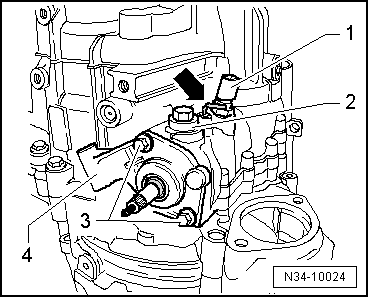

| Then insert differential -1-. |

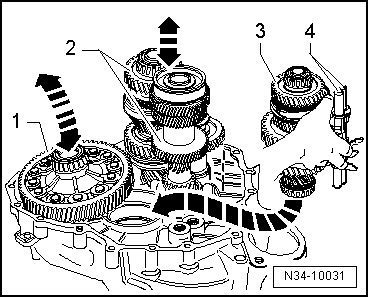

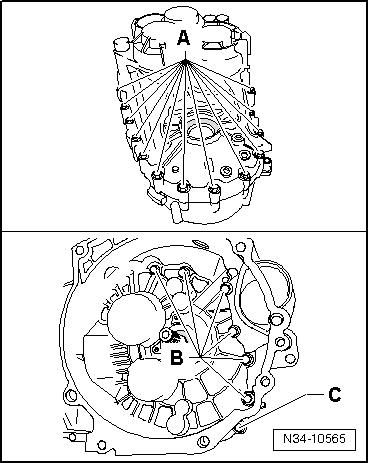

Note | A second mechanic will be required for further installation of shafts in clutch housing. |

| –

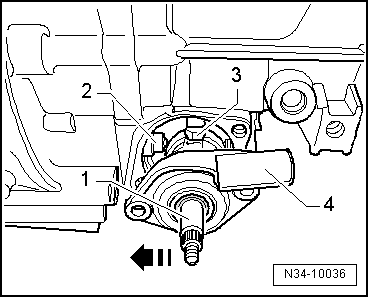

| Take output shaft for 1st through 4th gears -3- with selector rods -4- in the right hand as shown in figure. |

| –

| With the left hand, lift differential slightly. |

| –

| At the same time, a 2nd mechanic must slightly lift input shaft and output shaft for 5th and 6th gears and reverse gear -2- together with reverse gear shaft. |

| –

| Now insert output shaft for 1st through 4th gears in -direction of arrow-. |

| l

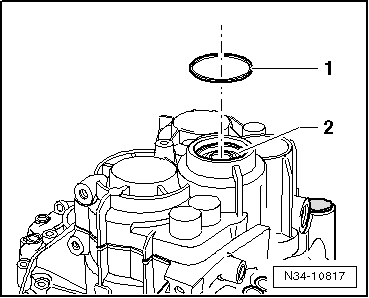

| The teeth of the input shaft, the output shafts and the final drive input gear of differential must mesh. |

| –

| Now, together with a second mechanic, place shafts and differential in their bearing seats. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note