Golf Mk4

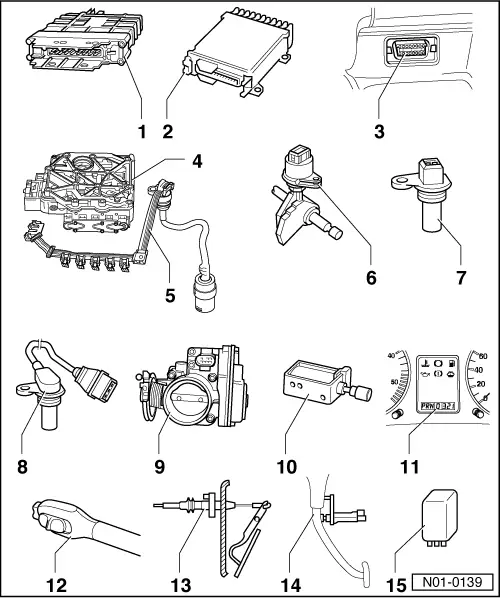

| Electrical and electronic components and their locations |

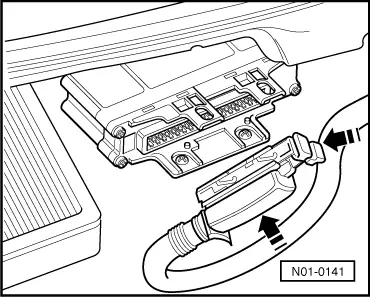

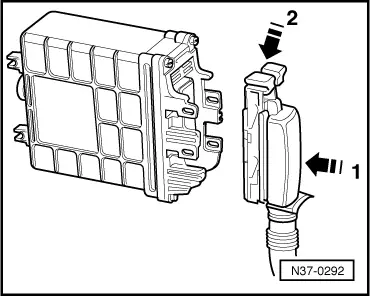

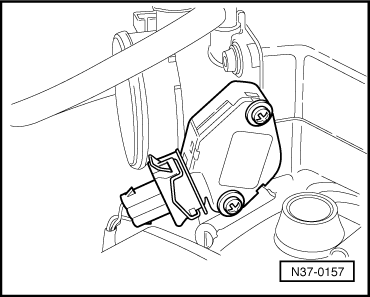

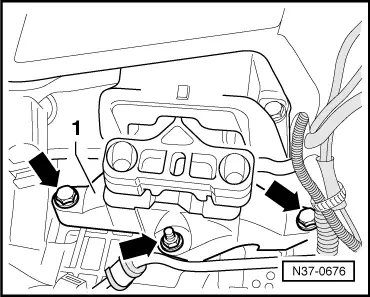

| 1 - | Control unit for automatic gearbox -J217- |

| Do not remove until electric and hydraulic faults have been eliminated as sources. |

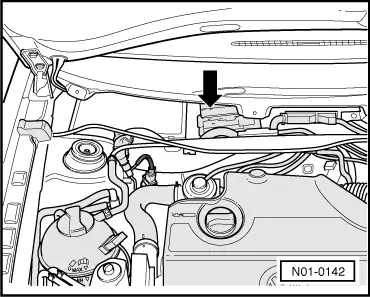

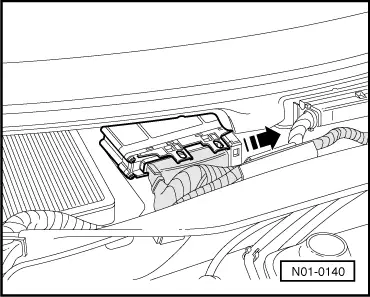

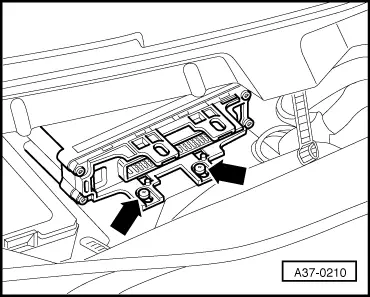

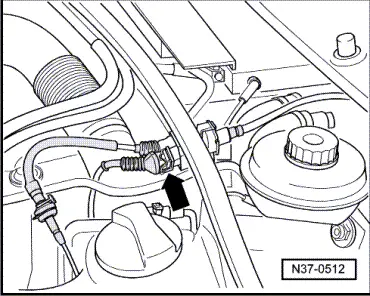

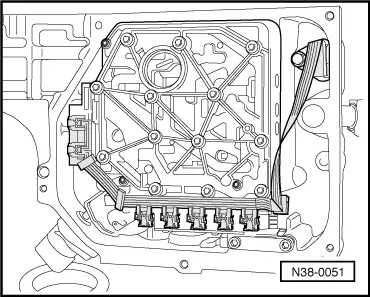

| q | Location → Fig. |

| q | Removing → Fig.. |

| q | Installing → Fig. |

| q | Can be checked in “guided fault finding”. |

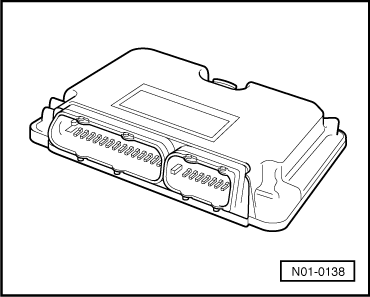

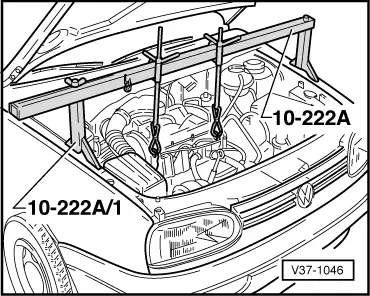

| 2 - | Engine control unit |

| q | Location and removing and installing → Fig.. |

| 3 - | Diagnostic connection |

| q | Location → Fig. |

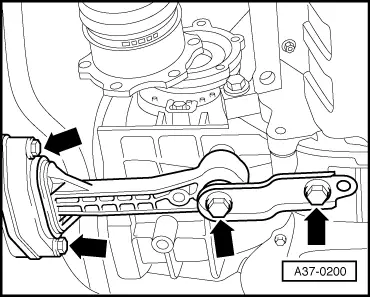

| 4 - | → Valve body |

| q | Location → Fig. |

| q | Removing and installing → Chapter |

| q | The → solenoid valves-N88-, -N89-, -N90-, -N91-, -N92-, -N93- and -N94- are attached to the → valve body. |

| q | Components can be checked in “guided fault finding”. |

| 5 - | Conductor strip with integrated gearbox oil temperature sender -G93- |

| q | Location → Fig. |

| q | Removing and installing → Chapter |

| q | -G93- can be checked in “guided fault finding” |

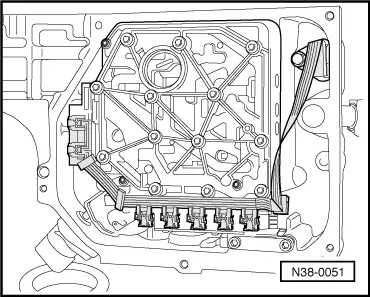

| 6 - | Multifunction switch -F125- |

| q | Location and removing and installing → Fig.. |

| q | Can be checked in “guided fault finding”. |

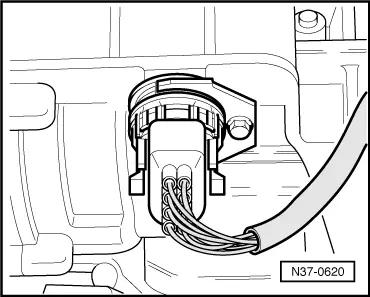

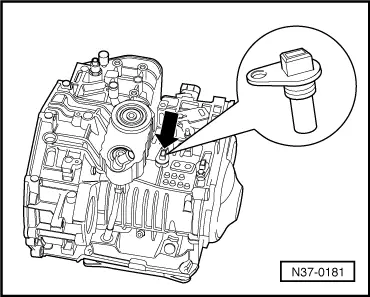

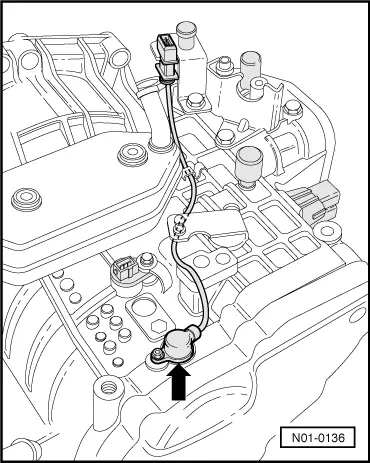

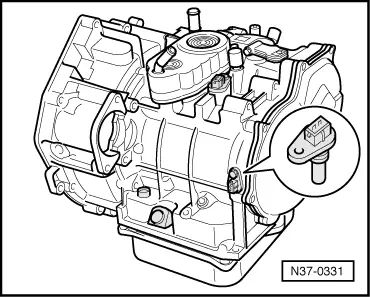

| 7 - | Gearbox speed sender -G38- |

| q | Location and removing and installing → Fig.. |

| q | 2-pin connector -T2- to wiring harness is white. |

| q | Can be checked in “guided fault finding”. |

| Do not interchange 2-pin connector -T2-, gearbox speed sender -G38- and driving speed sender -G68-! |

| 8 - | Vehicle speed sender -G68- |

| q | Location and removing and installing → Fig.. |

| q | 2-pin connector -T2- to wiring harness is black. |

| q | Can be checked in “guided fault finding”. |

| Do not interchange 2-pin connector -T2-, gearbox speed sender -G38- and driving speed sender -G68-! |

| 9 - | Throttle valve potentiometer -G69- or accelerator pedal position sender -G79- |

| q | More information → Anchor. |

| q | Can be checked in “guided fault finding”. |

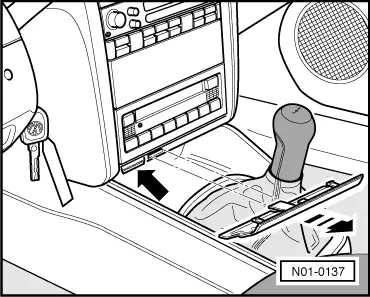

| 10 - | Selector lever lock solenoid -N110- |

| q | Location: the selector lever lock solenoid is located on the selector lever |

| q | Removing and installing → Chapter |

| q | Can be checked in “guided fault finding”. |

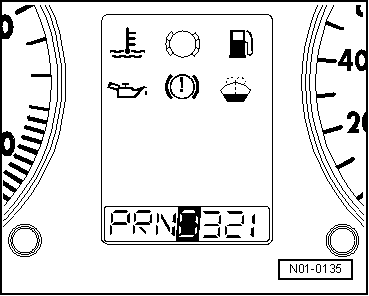

| 11 - | Selector lever position display -Y6- |

| q | Location → Fig. |

| q | Simultaneous illumination of all selector lever position display segments indicates gearbox emergency running mode. |

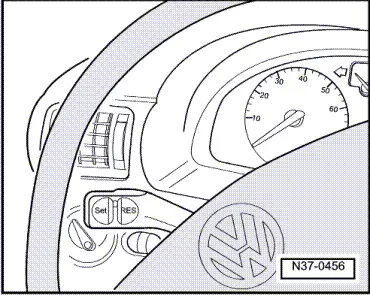

| 12 - | Cruise control system switch -E45- |

| q | Location → Fig. |

| q | Removing and installing → Electrical system; Rep. Gr.94. |

| q | Can be checked in “guided fault finding”. |

| 13 - | Kickdown switch -F8- |

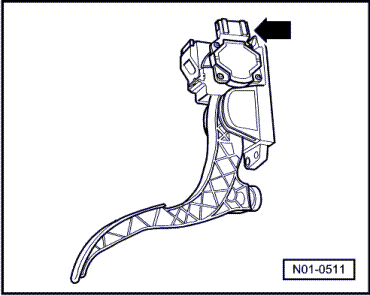

| q | Location in vehicles without EPC → Fig.. |

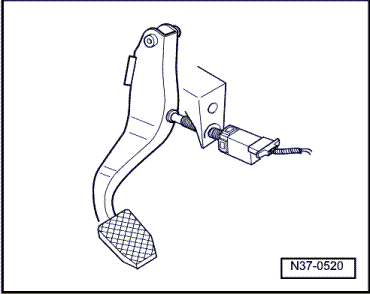

| q | Location in vehicles with EPC → Fig.. |

| q | Can be checked in “guided fault finding”. |

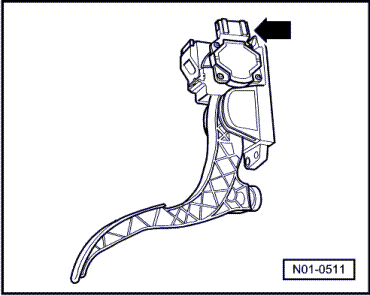

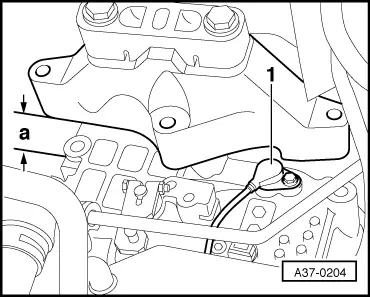

| 14 - | Brake light switch -F- or brake pedal switch -F47- |

| q | Location and removing and installing → Fig.. |

| q | Can be checked in “guided fault finding”. |

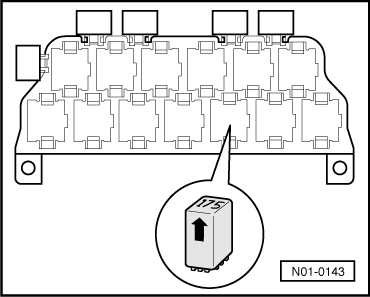

| 15 - | Starter inhibitor and reversing light relay -J226- |

| q | Location → Fig. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|