Golf Mk4

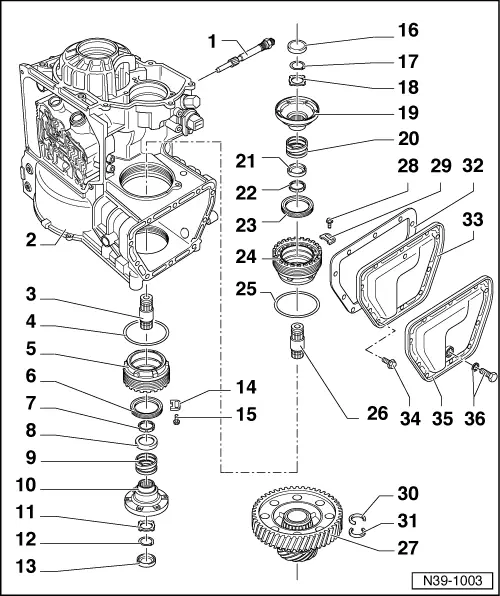

| Removing and installing differential |

| Special tools and workshop equipment required |

| t | Drive shaft fitting appliance -VW 391- |

| t | Oil seal extractor lever -VW 681- |

| t | Puller -3109- |

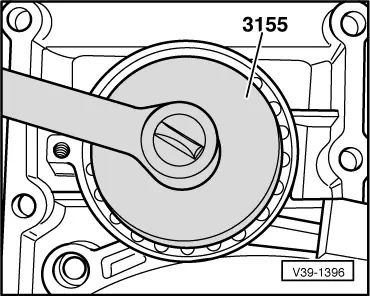

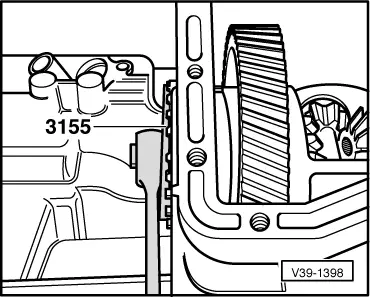

| t | Slotted nut wrench -3155- |

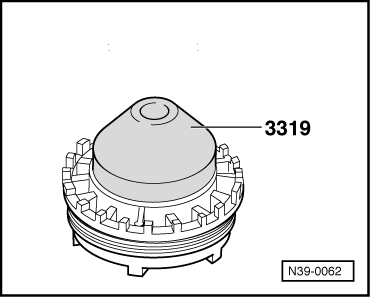

| t | Thrust piece -3319- |

|

| t | The pinion shaft does not need to be removed in order to remove and install the differential. |

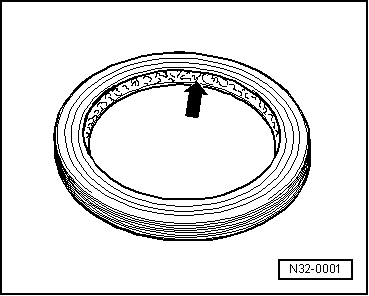

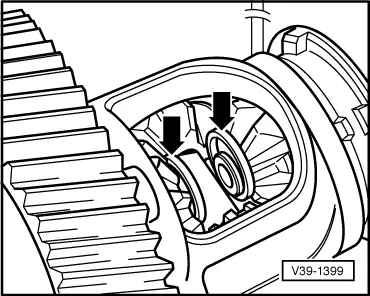

| t | If tapered roller bearings are to be reused, mark the adjusting ring → Fig.. |

| 1 - | Speedometer drive |

| q | Oil level must be measured here if the gearbox cover does not have a plug → Chapter. |

| 2 - | Gearbox housing |

| 3 - | Output shaft |

| q | Inner thread faces flange during installation → Item |

| q | Shaft must be removed before differential can be removed |

| q | Install only after adjusting differential |

| 4 - | O-ring |

| q | Always renew |

| 5 - | Adjusting ring |

| If tapered roller bearings are to be reused, mark the adjusting ring → Fig.. When reinstalled, it must be set to this position again. |

| q | Removing and installing → Fig. |

| q | If new tapered roller bearings are used, the differential must be adjusted again → Chapter |

| 6 - | Drive flange oil seal |

| q | Can be renewed with gearbox installed → Chapter. |

| q | Remove with oil seal extractor lever -VW 681- |

| q | Before installing, half-fill space between sealing lips with sealing grease -G 052 128 A1-. |

| q | Driving in → Fig. |

| 7 - | Tapered ring |

| q | Shoulder faces thrust washer |

| 8 - | Thrust washer |

| q | Place over compression spring |

| 9 - | Compression spring |

| 10 - | Drive flange |

| q | Always remove flange before removing inner retaining ring from differential bevel gear. This will prevent the force of the compression spring from hindering the removal of the inner securing ring. |

| q | Insert with tapered ring, thrust washer and compression spring |

| q | Removing and installing with gearbox installed in order to renew oil seal → Chapter |

| 11 - | Dished spring |

| 12 - | Retaining ring |

| 13 - | Sealing cover |

| 14 - | Locking element |

| 15 - | Bolt, 12 Nm |

| 16 - | Sealing cover |

| 17 - | Retaining ring |

| 18 - | Dished spring |

| 19 - | Drive flange |

| q | Always remove flange before removing inner retaining ring from differential bevel gear. This will prevent the force of the compression spring from hindering the removal of the inner securing ring. |

| q | Insert with tapered ring, thrust washer and compression spring |

| q | Removing and installing with gearbox installed in order to renew oil seal → Chapter |

| 20 - | Compression spring |

| 21 - | Thrust washer |

| q | Place over compression spring. |

| 22 - | Tapered ring |

| q | Shoulder faces thrust washer |

| 23 - | Drive flange oil seal |

| q | Can be renewed with gearbox installed → Chapter. |

| q | Remove with oil seal extractor lever -VW 681- |

| q | Before installing, half-fill space between sealing lips with sealing grease -G 052 128 A1-. |

| q | Driving in → Fig. |

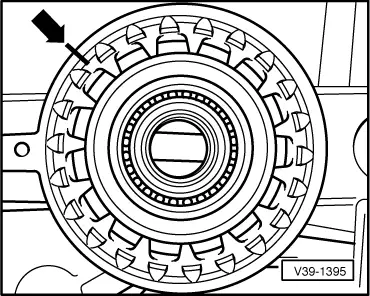

| 24 - | Bearing body, 150 Nm |

| q | Remove using slotted nut wrench -3155- |

| q | Installing → Fig. |

| 25 - | O-ring |

| q | Always renew |

| 26 - | Output shaft |

| q | Inner thread faces drive flange during installation → Item |

| q | Shaft must be removed before differential can be removed |

| q | Install only after adjusting differential |

| 27 - | Differential |

| q | Dismantling and assembling → Chapter |

| q | After adjusting differential, always secure bearing body → Item and adjusting ring → Item |

| 28 - | Bolt, 12 Nm |

| 29 - | Locking element |

| 30 - | Inner retaining ring |

| q | Keep in mind that during installation and removal, the compression spring should not be applying force. |

| q | Removing and installing → Fig. |

| 31 - | Inner retaining ring |

| q | Keep in mind that during installation and removal, the compression spring should not be applying force. |

| q | Removing and installing → Fig. |

| 32 - | Seal |

| q | Always renew |

| 33 - | Cover for final drive |

| q | “Older” version without inspection plug |

| q | As replacement part, only with inspection plug → Item |

| 34 - | Bolt, 28 Nm |

| q | Insert with locking fluid -AMV 185 101- |

| 35 - | Cover for final drive |

| q | “New” version with inspection plug |

| 36 - | Inspection plug |

| q | Checking gear oil with gearbox installed → Chapter. |

|

|

|

|

|

|

|

|

|

|

|

|