Golf Mk4

|

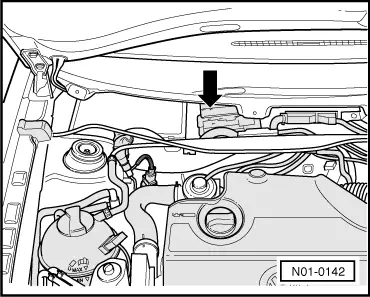

Gearbox: Electrical check

Electrical check

|

|

|

|

|

|

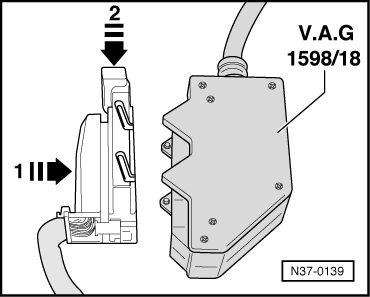

Using test box V.A.G 1598/18 the wiring can be checked according to current flow diagram.

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

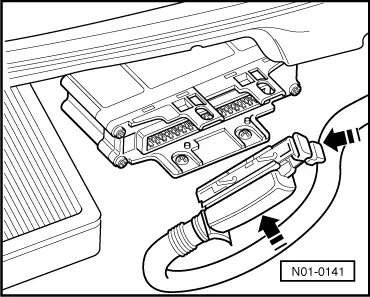

After electrical checks

Control unit -J217- multi-pin connector (68 pin) assignment (sockets on V.A.G 1598/18)

1) Only used on vehicles without Data bus. On vehicles with Data bus these chambers are not used. The control unit then receives this information from the Data bus, or sends the information or the Data bus (3 + 25).

1) Only used on vehicles without Data bus. On vehicles with Data bus these chambers are not used. The control unit then receives this information from the Data bus, or sends the information or the Data bus (3 + 25). List of test steps Only perform test steps for the relevant component as listed in fault finding table and measured value block.

|