Note | t

| Before carrying out further work, disconnect battery earth strap. Check whether a coded radio is fitted. Obtain anti-theft coding first if necessary. |

| t

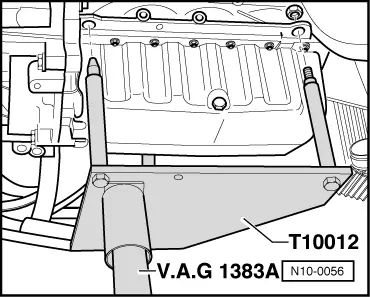

| The engine is removed downwards together with the gearbox. |

| t

| All cable ties which are opened or cut through when engine is removed must be replaced in the same position when engine is installed. |

WARNING | When doing any repair work, especially in the engine compartment, pay attention to the following due to the cramped conditions: |

| t

| Route all the various lines (e.g. for fuel, hydraulics, activated charcoal filter system, coolant and refrigerant, brake fluid and vacuum) and electrical wiring in their original positions. |

| t

| Ensure that there is sufficient clearance to all moving or hot components. |

|

| –

| With ignition switched off, disconnect earth strap from battery. |

| –

| All cable ties which are opened or cut through when engine is removed must be replaced in the same position when engine is installed. |

| –

| Remove battery and battery carrier. |

| –

| Vehicles with turbocharger: release clamps of connecting pipe between charge air cooler and intake manifold on intake manifold. |

WARNING | t

| The fuel and the fuel lines in the fuel system can become very hot (danger of scalding)! |

| t

| The fuel system is also under pressure! Before opening the system, place cloths around the connections. Then carefully loosen connection to release the pressure! |

| t

| Wear eye and hand protection when performing any type of repair work on the fuel system! |

|

| –

| Disconnect fuel supply and return lines at fuel filter. |

| –

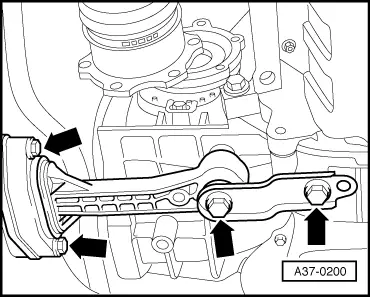

| Vehicles with an automatic gearbox: remove gate selector cable from gearbox: → Rep. Gr.37 |

| –

| Remove centre, left and right insulation trays → Rep. Gr.50 |

| –

| Pull connectors off thermal switch and radiator fan. |

| –

| Pull radiator coolant hoses off engine using hose clip pliers -V.A.G 1921-. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note