| t

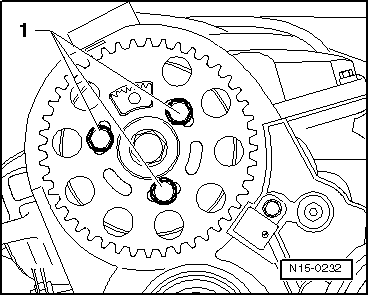

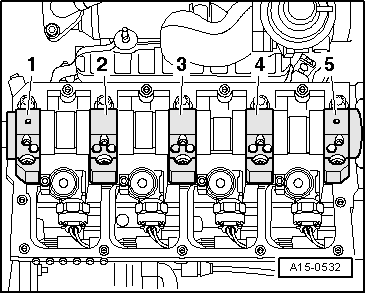

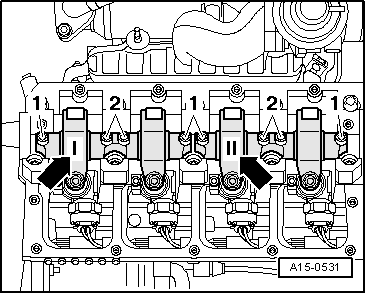

| When camshaft is installed, No. 1 cylinder cams must point upwards. |

| t

| Do not interchange used bearing shells (mark). |

| t

| When installing the camshaft, ensure proper seating of retaining lugs in bearing caps and cylinder head. |

| t

| Before installing bearing caps, ensure that cylinder head bolt washers are inserted in the cylinder head. |

| –

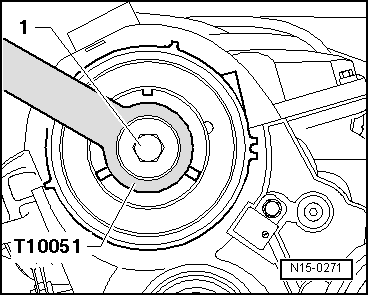

| Oil running surfaces of shell bearings. |

| –

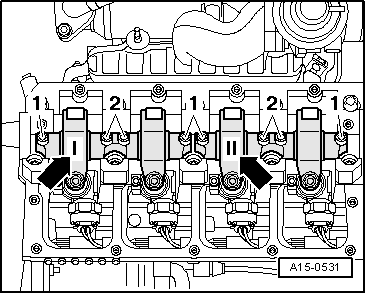

| Tighten bearing caps 2 and 4 alternately and diagonally to 8 Nm + turn 90° further (renew). |

| –

| Install bearing caps 5, 1 and 3 and also tighten to 8 Nm + turn 90° further (renew). |

Note | t

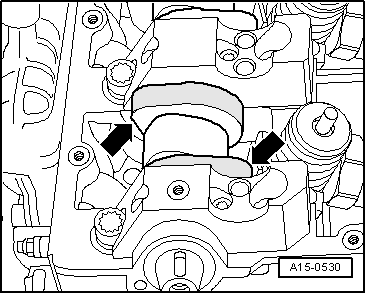

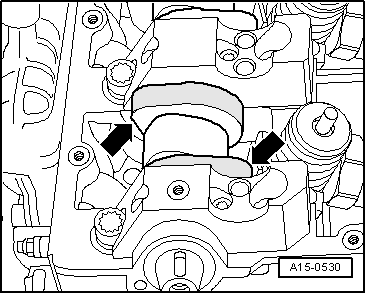

| Seal separating surfaces of bearing caps 1 and 5 with AMV 174 004 01 → Fig.. |

| t

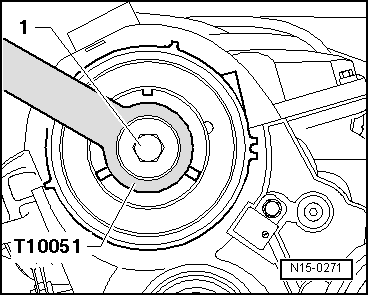

| Bearing cap 5 must be flush with outer edge of cylinder head, otherwise leaks can occur at the tandem pump. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note