Golf Mk4

Note

Note

|

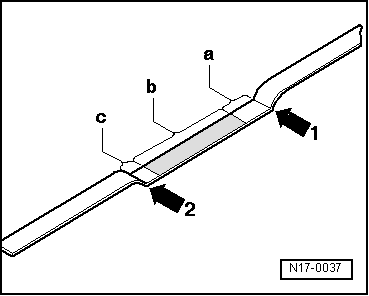

| 1 - | Seal |

| q | Slide on up to shoulder of connecting pipe → Item. |

| 2 - | Connecting pipe |

| 3 - | To breather housing of cap |

| 4 - | Clip |

| 5 - | Securing clip |

| 6 - | Plug, 15 Nm |

| 7 - | Seal |

| q | If sealing ring is leaking, nip open and replace. |

| 8 - | 1.4 bar oil pressure switch -F1-, 25 Nm |

| q | Black. |

| q | Checking → Chapter. |

| 9 - | Seal |

| q | If sealing ring is leaking, nip open and replace. |

| 10 - | Oil filter bracket |

| 11 - | 15 Nm + 1/4 turn (90°) further |

| q | Renew. |

| 12 - | Gasket |

| q | Renew. |

| q | Fit into lugs on oil cooler. |

| 13 - | Oil cooler |

| q | Ensure clearance to adjacent components. |

| q | See note → Chapter. |

| 14 - | 25 Nm |

| 15 - | Oil filter |

| q | Loosen with strap wrench. |

| q | Tighten by hand. |

| q | Observe installation instructions on oil filter. |

| 16 - | Plug, 40 Nm |

| q | Renew. |

| 17 - | Seal |

| q | Permanently attached to → Item. |

| 18 - | Spring |

| q | For pressure relief valve, approx. 4 bar. |

| 19 - | Piston |

| q | For pressure relief valve, approx. 4 bar. |

| 20 - | Gasket |

| q | Renew. |