| –

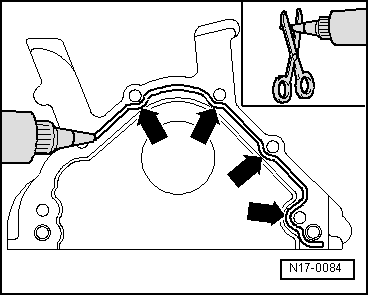

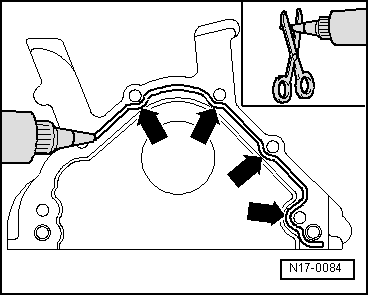

| Cut off tube nozzle at forward marking (Ø of nozzle approx. 3 mm). |

| –

| Apply silicone sealant -D 176 404 A2- to clean sealing surface of sealing flange, as shown. Sealant bead must be: |

| t

| Run bead along inner side of bolt holes -arrows-. |

Note | t

| Sealant bead should not be thicker, otherwise excess sealant may enter oil sump and plug up strainer in oil pump suction pipe, as well as drip onto crankshaft oil seal. |

| t

| Before applying sealant bead, cover sealing surface of oil seal with a clean rag. |

| t

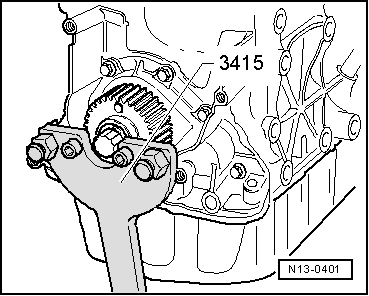

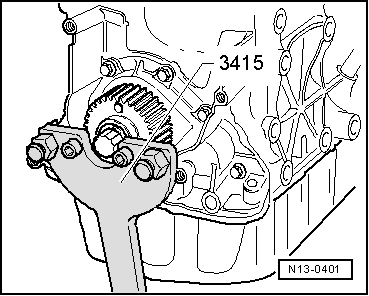

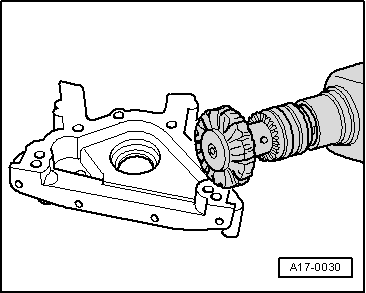

| When fitting sealing flange with oil seal installed, use guide sleeve -T10053/1-. |

| –

| Fit sealing flange immediately and lightly tighten all bolts. |

| –

| Tighten sealing flange securing bolts diagonally and alternately. Torque setting: 15 Nm. |

Note | Sealing compound must dry for approx. 30 minutes after installation. Only then fill engine oil. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note