-

‒ Insert in the cylinder block new dowel sleeves for centralising engine and gearbox.

-

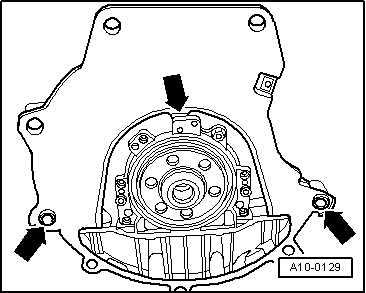

‒ →

Fit intermediate plate onto sealing flange and slide onto dowel sleeves -arrows-.

Models with a manual gearbox

-

‒ Lightly grease input shaft splines with G 000 100 grease.

-

‒ Check clutch and clutch operating mechanism, then install.

=> 5-speed manual gearbox 02J; Repair group 30; Servicing clutch control

-

‒ Install gear shift mechanism, adjust gear shift cables if necessary:

=> 5-speed manual gearbox 02J; Repair group 34; Servicing selector mechanism

Vehicles with automatic gearbox

-

‒ Install selector cable on gearbox, adjust if necessary:

=> Automatic gearbox 01M; Repair group 37; Servicing selector mechanism; Removing and installing cable

Vehicles with air conditioning

-

‒ Install air conditioner compressor:

=> Heating, air conditioning; Repair group 87; Removing and installing the compressor bracket

Continuation for all models

-

‒ When installing the engine/gearbox assembly, ensure sufficient clearance to engine and gearbox mountings and radiator.

- Align assembly mountings for engine and gearbox

.

- Assembly mounting tightening torques

.

-

‒ Install right-hand drive shaft and attach left-hand drive shaft to gearbox:

=> Running gear; Repair group 40; Removing and installing drive shafts

-

‒ Install front exhaust pipe

, Removing and installing parts of exhaust system.

-

‒ Installing vane pump for power assisted steering:

=> Running gear; Repair group 48; Assembly overview: Vane pump with hydraulic pipes

-

‒ Electrical connections and routing:

=> Electrical system; Repair group 97

-

‒ Install poly V-belt => page 13-11

.

-

‒ Install sound insulation centre, left and right-hand:

=> General body repairs, exterior; Repair group 50; Noise insulation (petrol engine) - Assembly overview

-

‒ Replenishing coolant => page 19-12

.

-

‒ Install secondary air pump.

-

‒ Adapting (matching) engine control unit to throttle valve control part => page 24-43

Adapting components and functions.

-

‒ Carry out a test drive and interrogate fault memory.

-

‒ If the fault memory has been erased or the engine control unit was disconnected from permanent positive, the readiness code must be generated again => page 24-43

, Adapting components and functions.

|