Golf Mk4

|

Removing and installing engine

Notes on removing

Note: During the further course of work the battery earth strap must be disconnected. Therefore please check first whether a coded radio is fitted. Obtain radio code first if necessary.

Warning:

When performing repair work, especially due to the confined conditions in the engine well, pay attention to the following:

=> Electrical system; Repair group 27; Battery; Removing and installing battery

Warning:

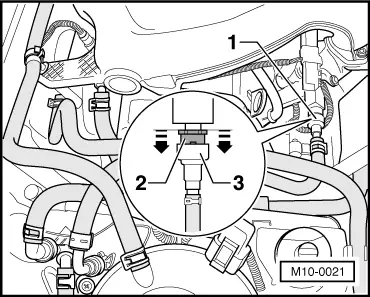

Fuel system is under pressure! Before opening the system place a cloth around the connection. Then release pressure by carefully loosening the connection. |

|

|

Note: Seal the intake ports in the intake manifold lower section with clean cloths.

Models with a manual gearbox

=> 5-speed manual gearbox 02J; Repair group 34; Servicing selector mechanism

=> 5-speed manual gearbox 02J; Repair group 30; Servicing clutch control Note: The clutch pedal must not be operated. Vehicles with automatic gearbox

Continuation for all models

=> Running gear; Repair group 48; Assembly overview: Vane pump with hydraulic pipes Vehicles with air conditioning

Continuation for all models

|

|

|

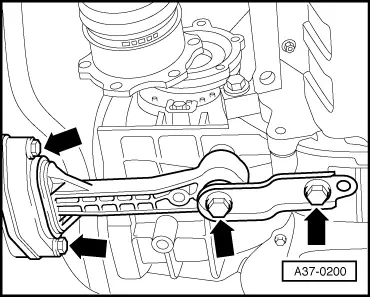

=> Running gear; Repair group 40; Removing and installing drive shafts |

|

|

|

|

|

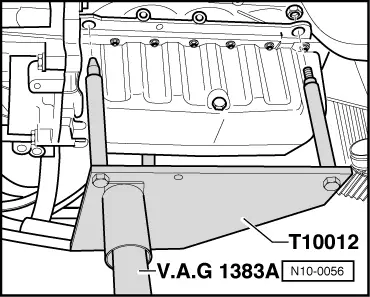

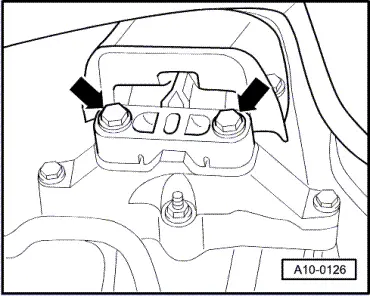

Note: To remove securing bolts, use step ladder VAS 5085. |

|

|

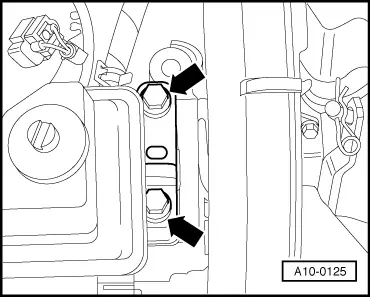

Note: Engine and gearbox must be guided carefully when lowering to prevent damage to the bodywork, hoses and lines/wiring. |