Golf Mk4

|

|

|

|

|

|

|

|

|

|

|

|

|

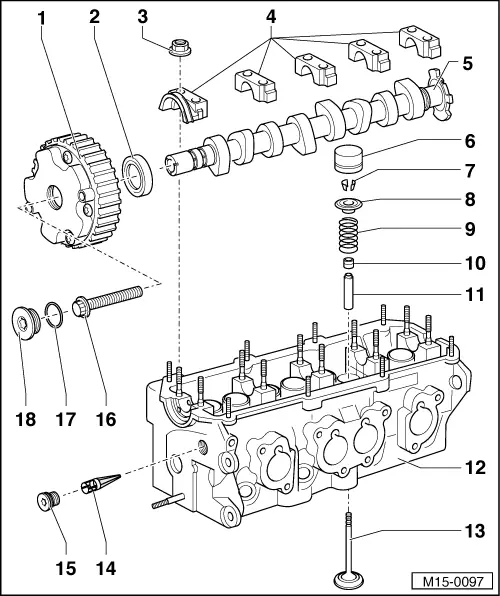

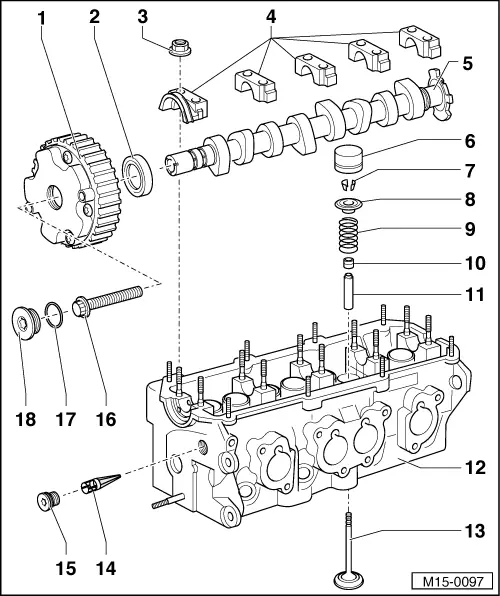

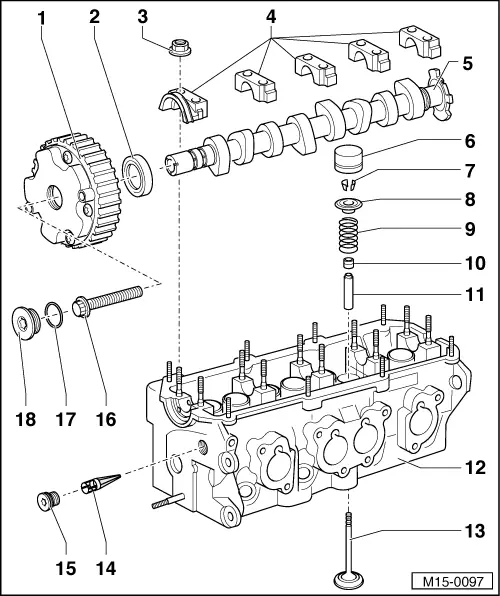

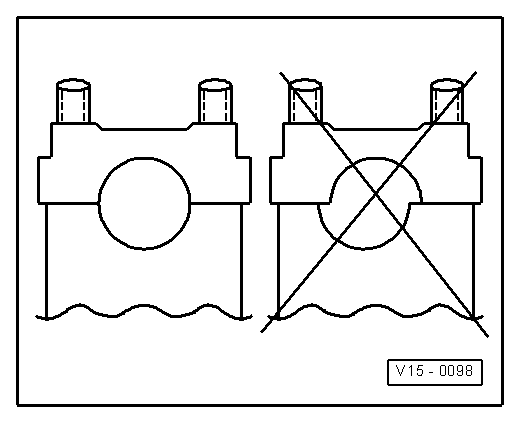

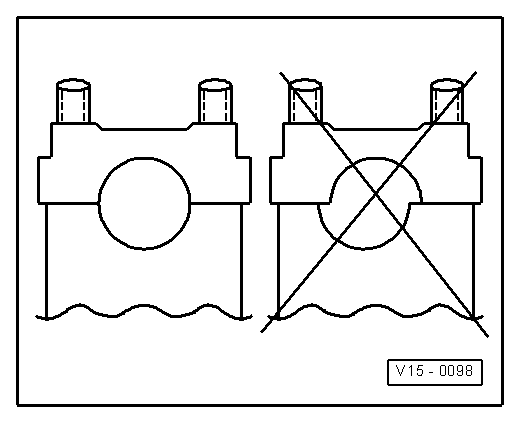

→ Fig. 3 Fitting position of camshaft bearing caps Note offset. Before installing camshaft fit bearing caps and determine fitting position. |

|

|

|

|

|

|

|

|

|

|

|

|

|

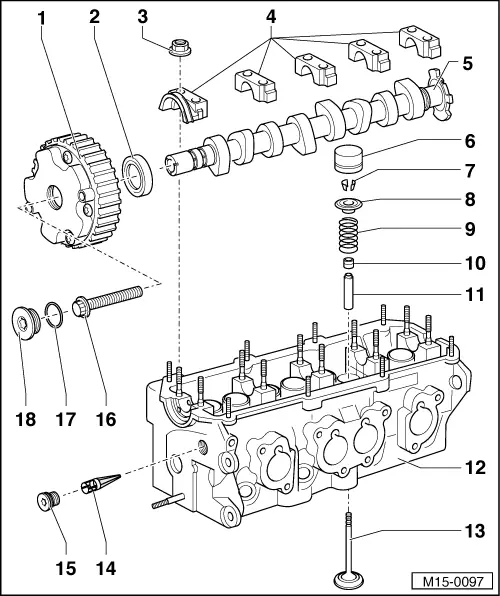

→ Fig. 3 Fitting position of camshaft bearing caps Note offset. Before installing camshaft fit bearing caps and determine fitting position. |