Golf Mk4

|

|

Note: This work sequence allows the fuel pump to run when the engine is not running.

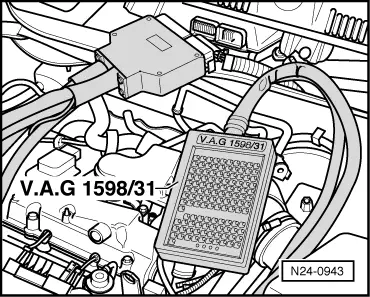

Checking for leaks

If the fuel loss is greater:

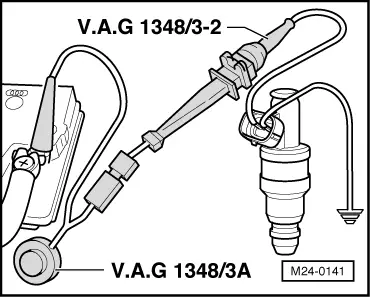

Note: Always renew seals. Checking quantity injected Test prerequisites

|

|

|

If the measured values of one or more injectors are above or below the prescribed specifications:

Perform installation of injectors in reverse order. When doing this note the following:

|