| –

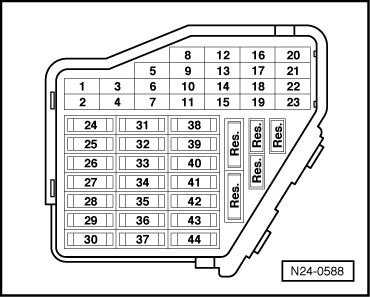

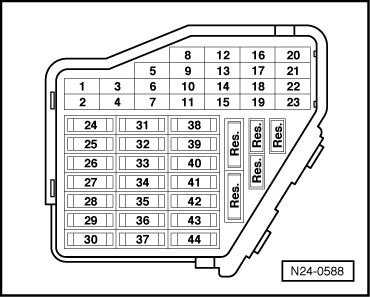

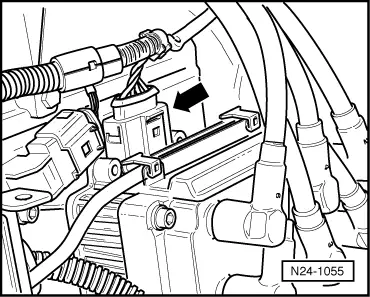

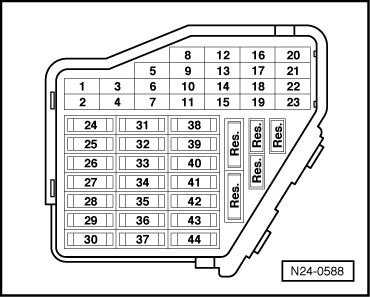

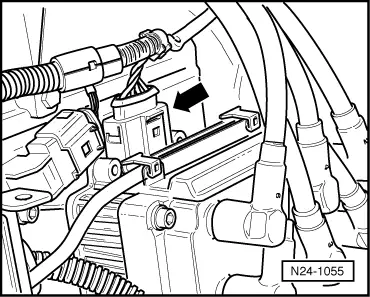

| Remove fuse No. 29 from fuse holder. |

| Removing fuse 29 interrupts the voltage supply to the injectors. |

| –

| Spark plug socket and extension -3122 B- is used in all engines to unscrew spark plugs. |

| –

| Check compression using compression tester -V.A.G 1763-. |

Note | Using compression tester ⇒ Operating instructions. |

| –

| Operate starter until tester shows no further pressure increase. |

| Maximum permissible difference between all cylinders: 3 bar |

| –

| Then reinstall spark plugs and ignition coils with output stage → Chapter. |

| After the test has been completed: |

| –

| Connect Vehicle diagnosis, testing and information system -VAS 5052-. |

| –

| Finish the vehicle system test so that any fault entries stored during assembly can be deleted automatically. |

| –

| Generate the readiness code in combination with a road test. |

| Observe applicable safety precautions during road test. |

| –

| Then carry out vehicle system test again and rectify any faults which may have occurred. |

|

|

|

Note

Note

Note

Note