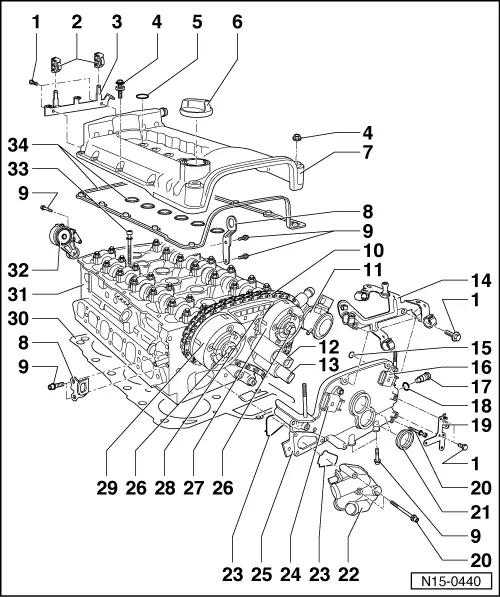

Golf Mk4

| Assembly overview - cylinder head |

| 1 - | 10 Nm |

| 2 - | Bracket |

| q | For fuel lines |

| 3 - | Retaining frame |

| 4 - | 10 Nm |

| q | With spacer sleeve and seal. |

| q | Renew seal if damaged. |

| 5 - | O-ring |

| q | Renew if damaged. |

| q | Lubricate before installing. |

| q | For ignition coil with output stage. |

| 6 - | Cap |

| q | Renew seal if damaged. |

| 7 - | Cylinder head cover |

| q | Removing and installing → Chapter |

| q | Renew if damaged. |

| 8 - | Lifting eye |

| 9 - | 23 Nm |

| 10 - | Camshaft timing chain |

| q | Before removing, mark direction of rotation (installation position) → Fig.. |

| q | Renew. → Chapter. |

| 11 - | Combination valve |

| q | Removing and installing → Chapter |

| q | Checking → Chapter |

| 12 - | Inlet camshaft adjuster valve 1 -N205- |

| q | For inlet camshaft. |

| q | Before removing, mark connector belonging to component. |

| 13 - | Exhaust camshaft adjuster valve 1 -N318- |

| q | For exhaust camshaft. |

| q | Before removing, mark connector belonging to component. |

| 14 - | Bracket |

| q | For wiring harness. |

| 15 - | O-ring |

| q | For sealing oil channel. |

| q | Renew. |

| q | Lubricate before installing. |

| 16 - | Hall sender 2 -G163- |

| q | For exhaust camshaft. |

| q | Before removing, mark connector belonging to component. |

| 17 - | Chain tensioner, 40 Nm |

| q | For camshaft timing chain → Item |

| q | Only rotate engine when chain tensioner is installed. |

| 18 - | Seal |

| q | Renew if damaged or leaking. |

| 19 - | Bracket |

| q | For wiring harness and earth connection |

| 20 - | 8 Nm |

| 21 - | Seal |

| q | For inlet camshaft adjuster valve 1 -N205- → Item and exhaust camshaft adjuster valve 1 -N318- → Item |

| q | Renew if damaged or leaking. |

| q | Installing → Fig.. |

| 22 - | Thermostat housing |

| q | Removing and installing → Chapter |

| q | Assembly overview → Chapter. |

| q | Coolant hose schematic diagram → Chapter. |

| 23 - | Seal |

| q | Renew. |

| 24 - | Hall sender -G40- |

| q | For inlet camshaft. |

| q | Before removing, mark connector belonging to component. |

| 25 - | Cover |

| q | Can be removed and installed with engine installed. |

| q | Removing and installing → Chapter |

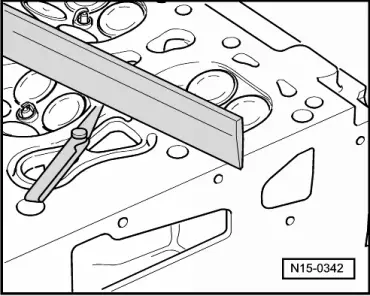

| q | If only cover has been removed, prepare cylinder head gasket for assembly → Fig.. |

| q | With O-ring for sealing oil channel → Item |

| 26 - | 60 Nm + 1/4 turn (90°) further |

| q | Renew. |

| q | Contact surface of sender wheel must be dry around bolt head when assembled. |

| q | To remove and install counterhold with 32 mm open-end spanner on camshaft → Chapter |

| 27 - | Exhaust camshaft adjuster |

| q | Identification: 32A. |

| q | Rotate engine only with camshaft adjuster installed. |

| q | Removing and installing → Chapter |

| 28 - | Guide rail |

| q | For camshaft timing chain → Item |

| q | Clipped into valve timing housing. |

| 29 - | Inlet camshaft adjuster |

| q | Identification: 24E |

| q | Rotate engine only with camshaft adjuster installed. |

| q | Removing and installing → Chapter |

| 30 - | Cylinder head gasket |

| q | Metal gasket. |

| q | Renew. |

| q | After renewing, renew entire coolant. |

| 31 - | Cylinder head |

| q | Check for distortion → Fig.. |

| q | Removing and installing → Chapter |

| q | After renewing, renew entire coolant. |

| 32 - | Tensioning element |

| q | For poly V-belt. |

| q | Removing and installing poly V-belt → Chapter. |

| 33 - | Cylinder head bolt |

| q | Renew. |

| q | Follow installation instructions and sequence when loosening and tightening → Chapter. |

| 34 - | Gasket for cylinder head cover |

| q | Renew if damaged or leaking. |

| q | Note installation position. |

|

|