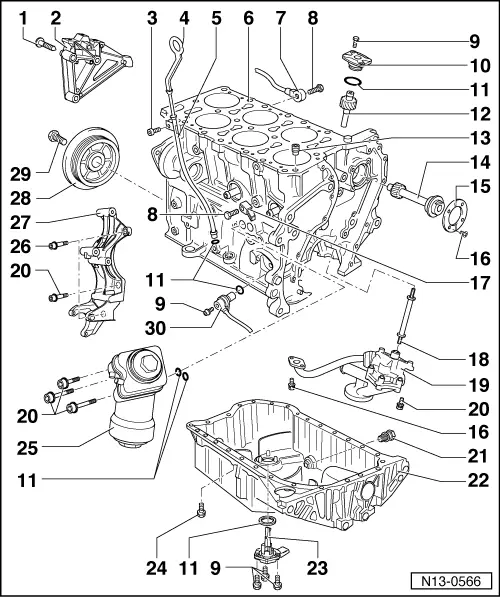

Golf Mk4

| Part II: Assembly overview - crankshaft drive |

| 1 - | 45 Nm |

| 2 - | Engine bracket |

| 3 - | 5 Nm |

| q | Secured to intake manifold. |

| 4 - | Dipstick |

| q | The oil level must not be above the max. mark! |

| q | Markings → Fig.. |

| 5 - | Guide tube |

| q | For dipstick. |

| q | Secured with bolt to intake manifold. |

| 6 - | Cylinder block |

| q | Removing and installing sealing flange and dual-mass flywheel → Chapter. |

| q | Removing and installing crankshaft → Chapter. |

| q | Dismantling and assembling pistons and conrods → Chapter. |

| 7 - | Knock sensor 1 -G61- |

| q | Fitting location: between cylinder 1 and cylinder 3. |

| 8 - | 20 Nm |

| q | The torque setting influences the function of the knock sensor. |

| 9 - | 10 Nm |

| 10 - | Oil pump drive cover |

| 11 - | O-ring |

| q | Renew. |

| q | Lubricate before installing. |

| 12 - | Oil pump drive |

| 13 - | Oil non-return valve, 5 Nm |

| q | Note installation position. |

| q | Clean if badly soiled |

| q | See note → Chapter. |

| 14 - | Intermediate shaft |

| 15 - | Thrust washer |

| 16 - | 10 Nm |

| q | Insert with locking fluid „D6“. |

| 17 - | Knock sensor 2 -G66- |

| q | Fitting location: between cylinder 4 and cylinder 6. |

| 18 - | Drive shaft |

| q | For oil pump drive. |

| 19 - | Oil pump |

| q | Dismantling and assembling → Chapter. |

| q | Coat oil pressure pipe on cylinder block and oil pump housing with sealant AMV 188 001 02 |

| 20 - | 25 Nm |

| 21 - | Oil drain plug, 30 Nm |

| q | Renew seal |

| 22 - | Oil sump |

| q | Removing and installing → Chapter |

| 23 - | Oil level and oil temperature sender -G266- |

| 24 - | 12 Nm |

| 25 - | Oil filter housing |

| q | Dismantling and assembling → Chapter. |

| q | Coolant hose schematic diagram → Chapter. |

| 26 - | Fitting bolt, 25 Nm |

| 27 - | Compact bracket |

| q | For alternator, air conditioner compressor and power-assisted steering vane pump |

| 28 - | Vibration damper |

| q | Removing and installing poly V-belt → Chapter. |

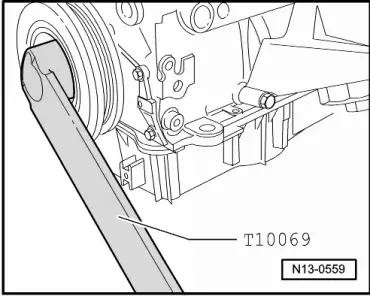

| 29 - | 100 Nm + 1/2 turn (180°) further |

| q | Renew. |

| q | To loosen and tighten, use counterhold -T10069- → Fig. |

| q | Tighten using torque wrench -V.A.G 1601-. |

| 30 - | Engine speed sender -G28- |

Note

Note

|

|