| Checking air mass meter -G70- |

| Engine codes AGR, AHF, ALH, ASV |

| The air mass meter signal is used by the control unit to calculate the quantity injected and to control the required exhaust gas recirculation. The smaller the signal from air mass meter -G70- the smaller the quantity of fuel injected. |

| Special tools and workshop equipment required |

| t

| Fault reader -V.A.G 1551- or vehicle system tester -V.A.G 1552- with diagnosis cable -V.A.G 1551/3- |

| t

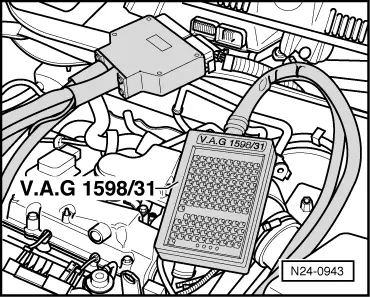

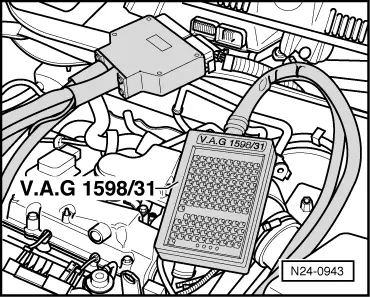

| Adapter cable, 121-pin -V.A.G 1598/31- |

| t

| Hand multimeter -V.A.G 1526C- or multimeter -V.A.G 1715- |

| t

| Auxiliary measuring set -V.A.G 1594C- |

| –

| Connect fault reader -V.A.G 1551- or vehicle system tester -V.A.G 1552- and select engine electronics control unit with “address word 01”. Engine must be idling. (Connecting fault reader and selecting engine electronics control unit → Chapter.) |

WARNING | Secure fault reader to rear seat and operate from this position. |

|

|

|

|