| Checking needle lift sender -G80- |

| The needle lift sender signal is required to determine the commencement of injection. If it fails, the commencement of injection switches to open-loop control (depending on engine speed and load). During normal operation, the commencement of injection is controlled by a closed-loop function (depending on engine speed, load and temperature). |

| Special tools and workshop equipment required |

| t

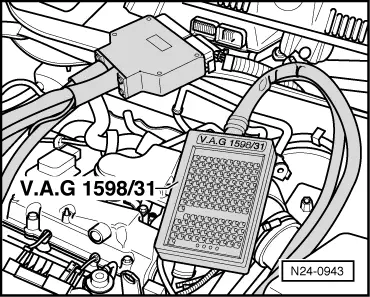

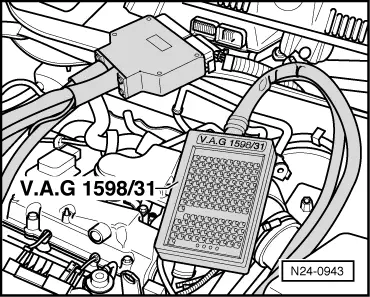

| Adapter cable, 121-pin -V.A.G 1598/31- |

| t

| Hand multimeter -V.A.G 1526C- or multimeter -V.A.G 1715- |

| t

| Auxiliary measuring set -V.A.G 1594C- |

| –

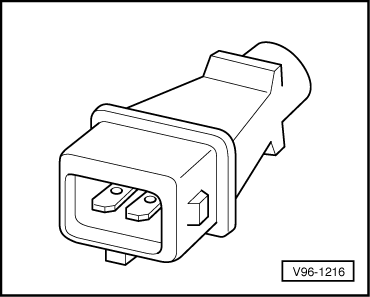

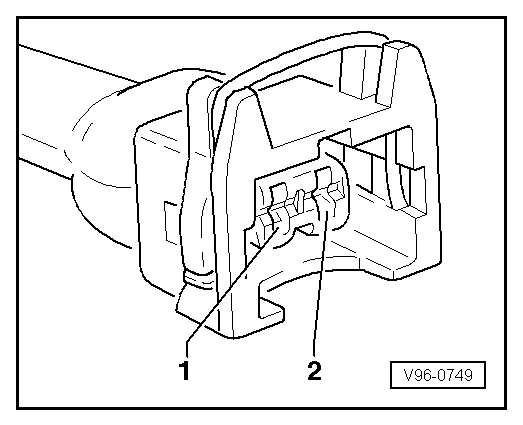

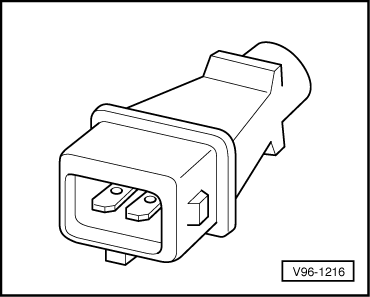

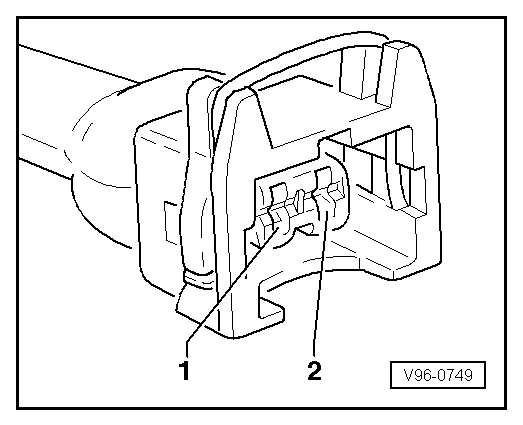

| Disconnect connector for needle lift sender -G80- → Chapter. |

|

|

|