| Specification in display zone 3: 3.0...5.0° BTDC |

| If the specifications are not reached: |

| –

| Check commencement of injection valve as follows: |

| –

| Press keys 0 and 6 for function “End data transfer” and confirm entry with Q key. |

| Engine codes AGR, AHF, ALH |

| Continuation for all engine codes |

|

|

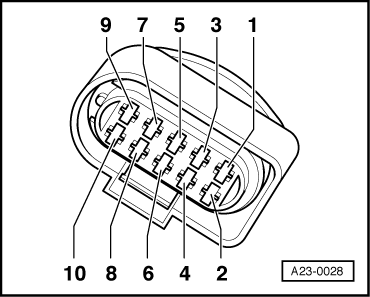

System in basic setting 4 -> | 880 rpm ret. 3.9 ° BTDC 74 % |

|