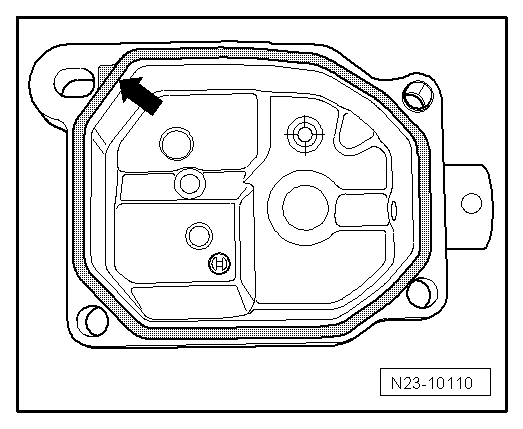

| Sealing quantity adjuster |

| Special tools and workshop equipment required |

| t

| Torque wrench -V.A.G 1331- |

| t

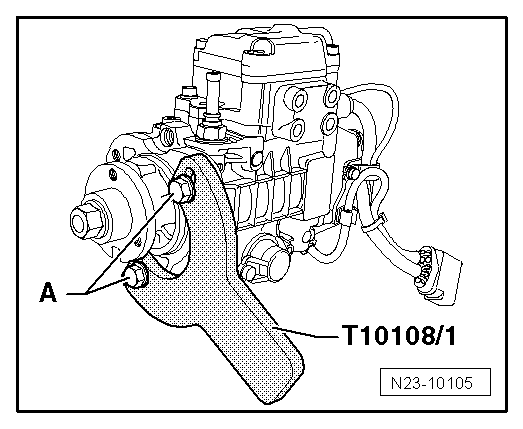

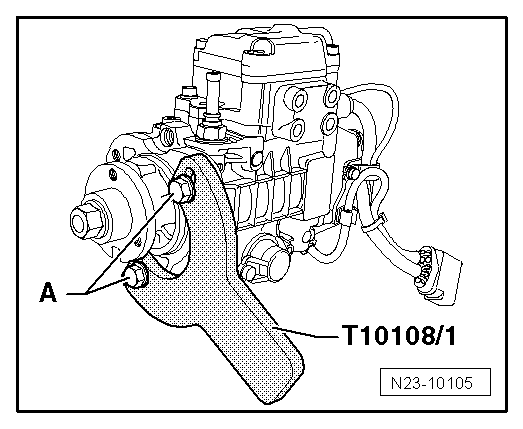

| Additional bracket -T10108/1- |

| t

| Vehicle diagnosis, testing and information system -VAS 5051- |

| –

| Set the injection quantity of the injection pump as follows: |

| Mechanical basic setting of engine OK. |

| Coolant temperature must be at least 80 °C. |

| –

| Connect vehicle diagnosis, testing and information system -VAS 5051- → Chapter. When doing this, the engine must be running at idling speed. |

| –

| Select operating mode “Self-diagnosis”. |

| –

| Press “Engine electronics” button on display. |

| –

| Press “Read measured value block” button on display. |

| –

| Select “1.-.Display group 1” on the keyboard. |

| –

| Observe the value see from the top at the second position. (equates to 2.2...9 mg/stroke). |

| –

| Make a note of the injection quantity. |

| –

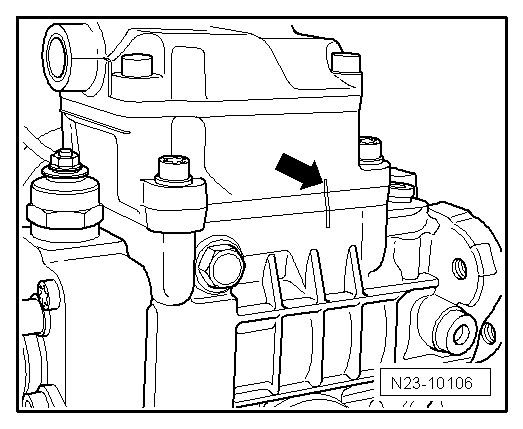

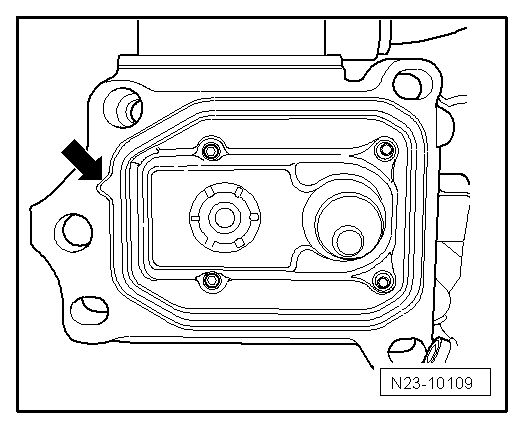

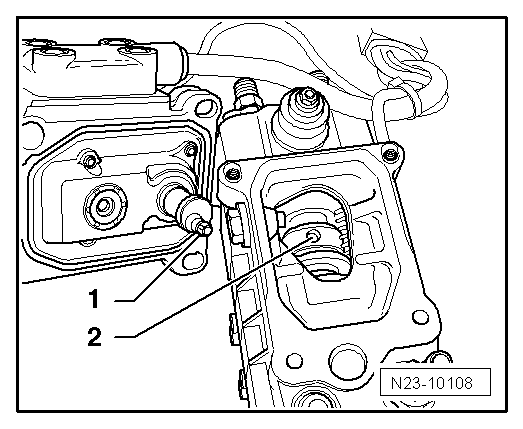

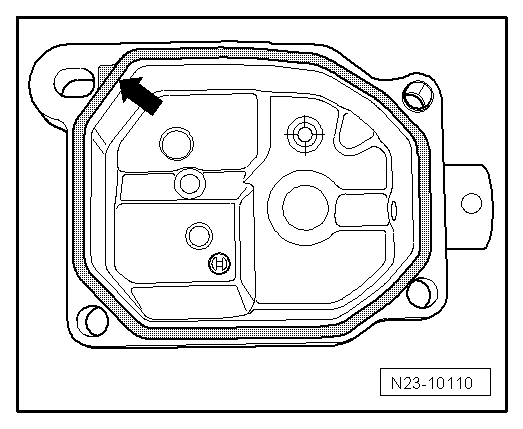

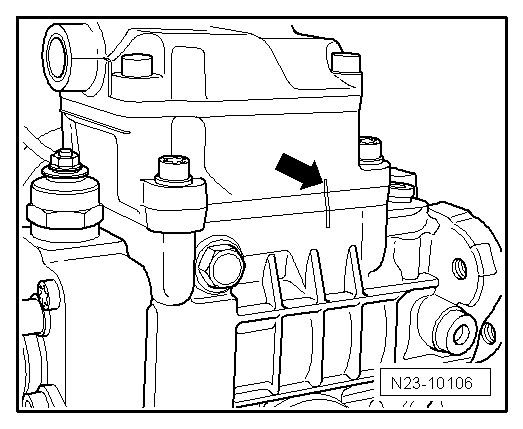

| Remove return connection → Item and drain the injection pump by holding it with the return hole down. Catch escaping fuel. |

| –

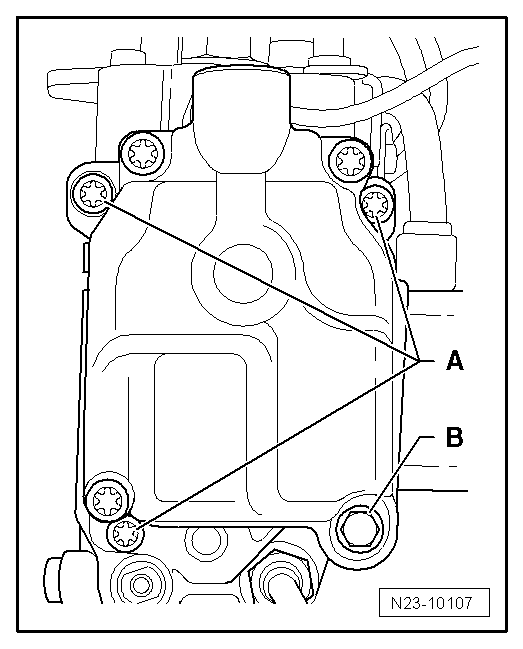

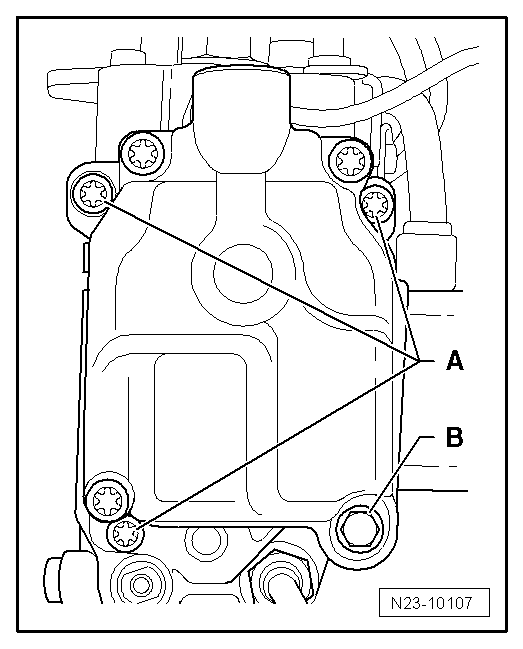

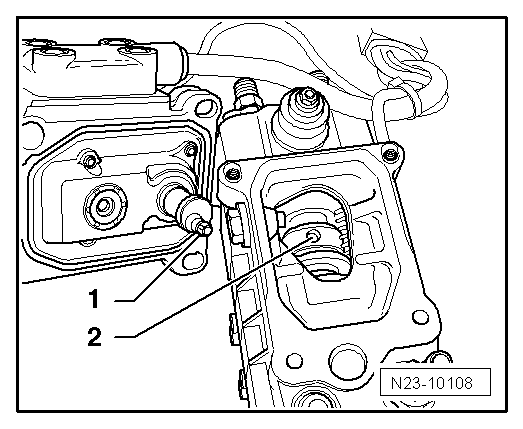

| Remove the additional bracket -T10108/1- on the injection pump flange and tight the bolts -A- to 20 Nm. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note