Golf Mk4

|

Servicing ignition system

Checking ignition coils with output stage

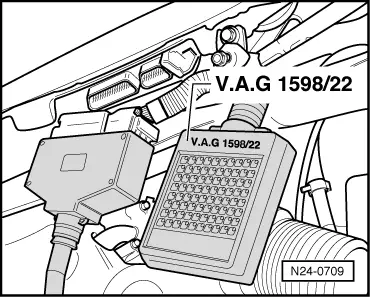

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

Check conditions

|

|

|

Note:

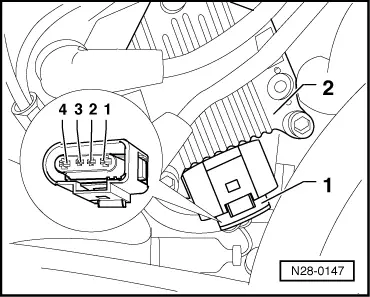

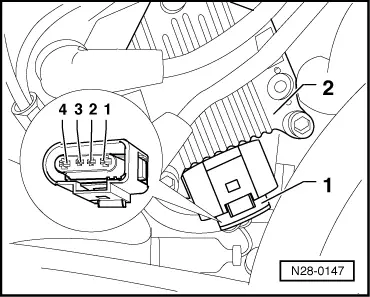

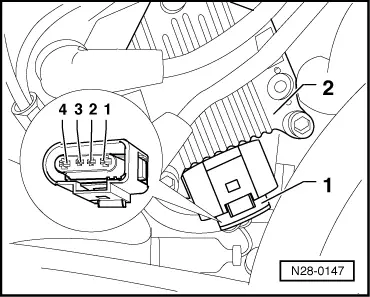

Checking voltage supply |

|

|

If no voltage is present: |

|

|

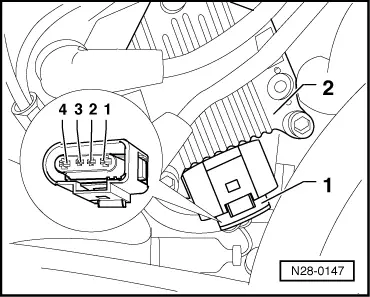

Checking activation |

|

|

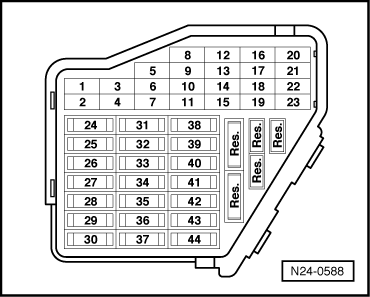

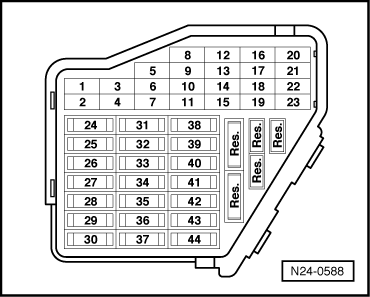

Note: Removing fuse 32 interrupts the voltage supply to the injectors. |

|

|

If the LED flickers and there is voltage between contacts 2 + 4:

The LED does not flicker:

|

|

|

|

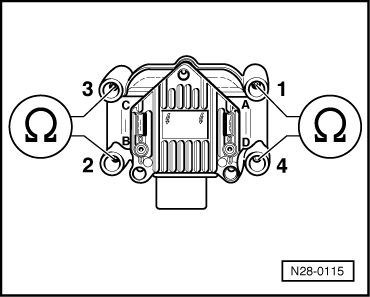

Checking wiring

|

|

|

If no wiring fault is detected and voltage was present between contacts 2+4:

|

|

|

|

Checking secondary winding

If the specifications are not attained: |