-

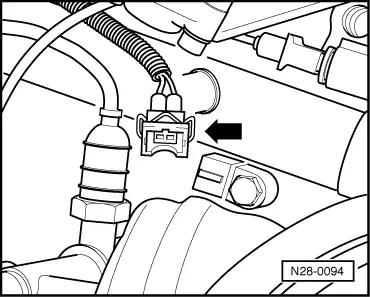

‒ →

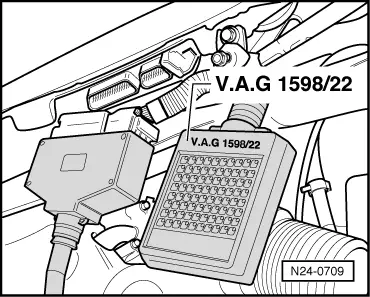

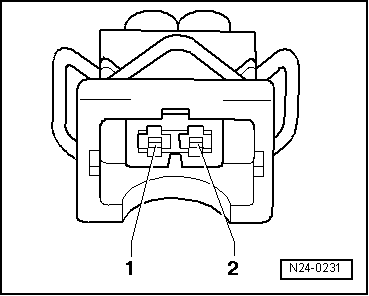

Check wiring between test box and 2 pin connector for open circuit using current flow diagram.

G61:

G66:

Contact 1+socket

68

60

Contact 2+socket

67

67

Wire resistance: Max. 1.5 ω

-

‒ Additionally check wires for short to one another.

G61:

G66:

Contact 1+socket

67

67

Specification: ∞ω

If no wiring fault is detected:

-

‒ Remove insulation tray.

=> General body repairs; Repair group 50; Removing insulation tray

-

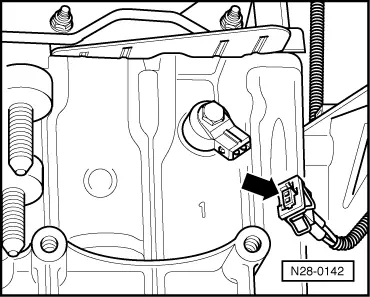

‒ Loosen appropriate knock sensor and tighten again to 20 Nm.

-

‒ Carry out test drive.

- During the road test the following operating conditions must be fulfilled:

-

‒ The coolant temperature must exceed 80 °C .

-

‒ When the temperature is reached, the operating conditions

Idling

Part throttle

Full throttle

Overrun

must be attained several times.

-

‒ At full throttle the speed must exceed 3500 rpm.

-

‒ Again interrogate the control unit fault memory.

If the fault is still present (fault again in fault memory):

-

‒ Replace appropriate knock sensor (G61 and/or G66) =>Page 28-8

.

|