Golf Mk4

|

|

Checking activation and voltage supply Warning!

Fuel system is under pressure! Before opening the system place a cloth around the connection. Then release pressure by carefully loosening the connection.

|

|

|

If the LED does not flicker on any cylinder: |

|

|

If the LED does not light up:

If the LED flickers on one or several cylinders: |

|

|

|

|

|

|

|

|

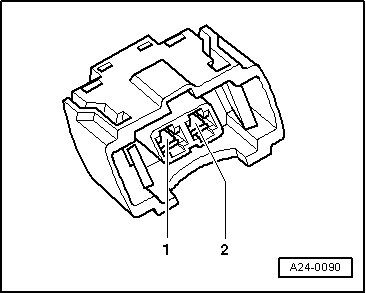

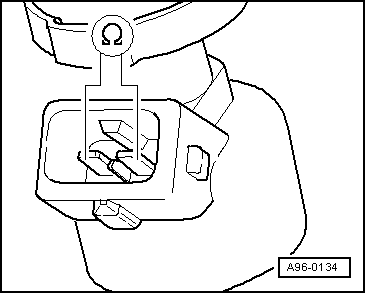

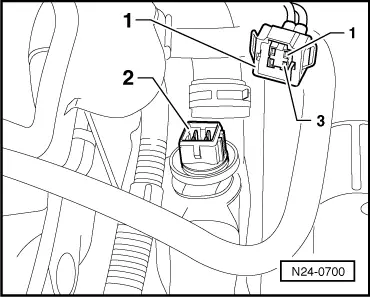

Checking resistance of injectors

When the engine is warm the resistance will be approx. 4...6 ωhigher.

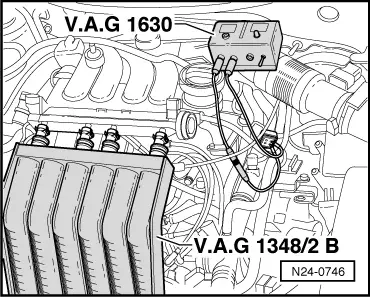

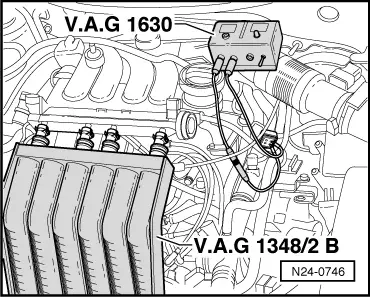

Checking spray pattern and for leaks |

|

|

|

Warning!

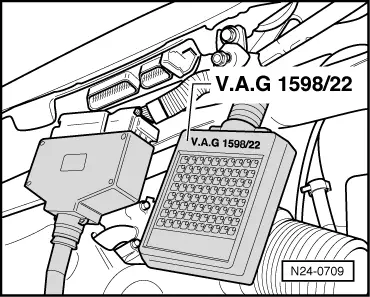

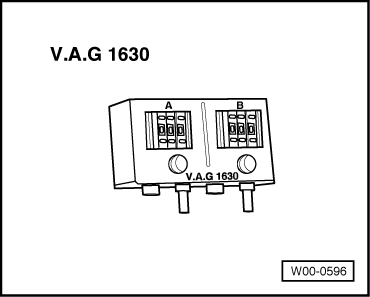

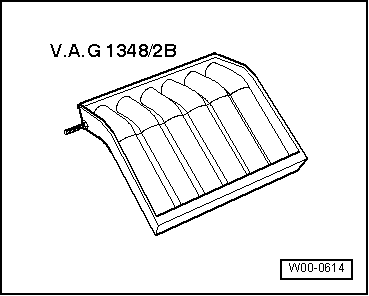

Fuel system is under pressure! Before opening the system place a cloth around the connection. Then release pressure by carefully loosening the connection. Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

|

|

|

Test sequence

|

|

|

|

|

|

|

|

|

Note: When installing the injectors ensure that the O rings are not damaged. |