Golf Mk4

| II - Assembly overview - wheel bearing |

| Special tools and workshop equipment required |

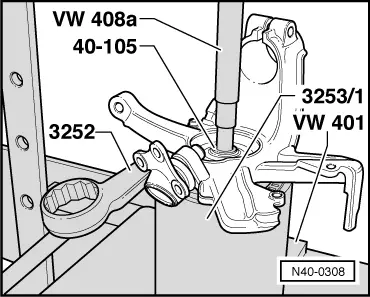

| t | Thrust plate -VW 401- |

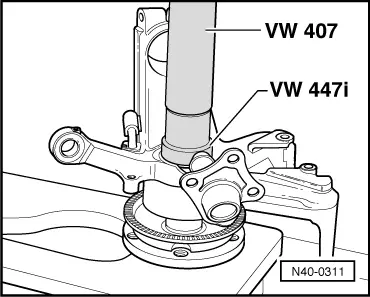

| t | Press tool -VW 407- |

| t | Press tool -VW 408 A- |

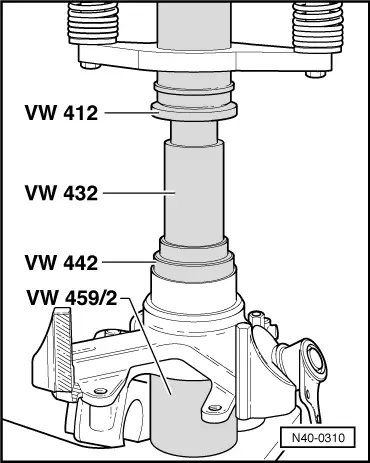

| t | Press tool -VW 412- |

| t | Thrust piece -VW 432- |

| t | Thrust piece -VW 442- |

| t | Thrust plate -VW 447 i- |

| t | Removal and installing tool -VW 459/2- |

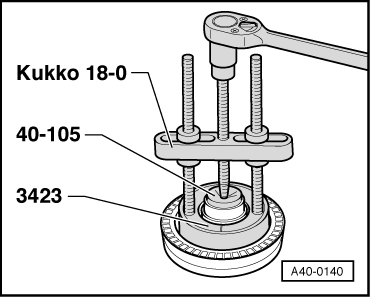

| t | Thrust plate -40 - 105- |

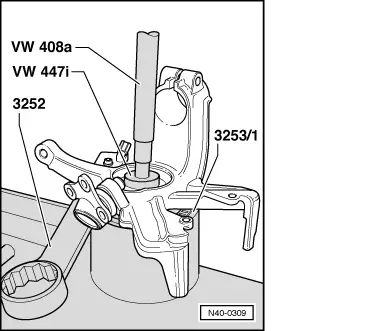

| t | Ring spanner, 46 mm -3252 A- |

| t | Assembly tool -3253- |

| t | Grip tool -3423- |

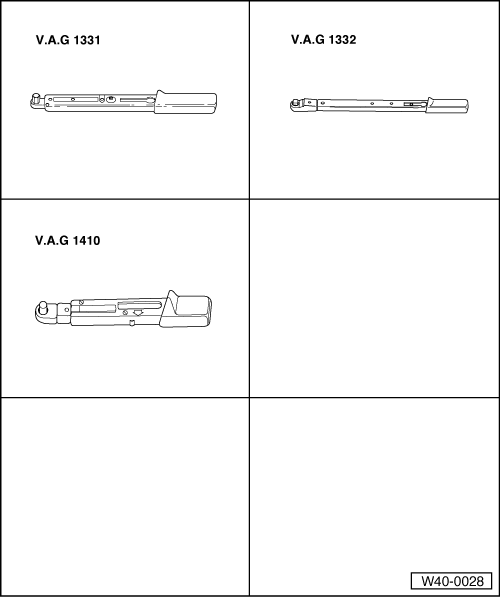

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

| t | Torque wrench -V.A.G 1410- |

Note

Note| t | If a vehicle has to be moved after the drive shaft has been removed, first install an outer joint instead of the drive shaft and tighten to 50 Nm because otherwise the wheel bearing will be damaged. |

| t | It is not permitted to weld or straighten suspension parts which bear loads or locate the front wheels |

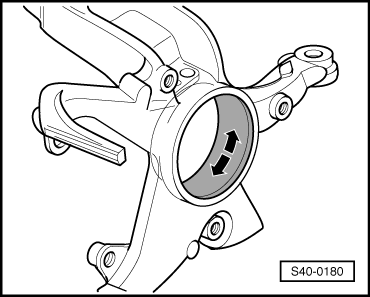

| t | Always renew self-locking nuts. |

| t | Always renew corroded nuts and bolts. |

| 1 - | Drive shaft |

| q | For special model “Golf GTI 132 kW”. |

| q | Pulling drive shaft out of wheel hub and pressing in ⇒ Removing and installing drive shafts → Chapter |

| 2 - | Drive shaft |

| q | Pulling drive shaft out of wheel hub and pressing in ⇒ Removing and installing drive shafts → Chapter |

| 3 - | Speed sensor |

| 4 - | Hexagon socket head bolt, 10 Nm |

| 5 - | Suspension strut |

| 6 - | Hexagon bolt |

| q | Renew each time after removing. |

| q | The tip of the hexagon bolt must face forwards. |

| 7 - | Track rod ball joint |

| 8 - | Self-locking nut |

| q | 60 Nm and turn 90° further. |

| q | Never less than 90°! |

| q | Turning angle tolerance 90° to 120°. |

| q | Renew each time after removing. |

| 9 - | Self-locking nut, 45 Nm |

| q | Renew each time after removing. |

| 10 - | Wheel bearing housing |

| For vehicles: |

| q | With petrol engines up to and including 92 kW. |

| q | With SDI or TDI engine. |

| 11 - | Swivel joint |

| q | Checking → Chapter. |

| q | Removing and installing → Chapter. |

| 12 - | Self-locking nut, 45 Nm |

| q | Renew each time after removing. |

| 13 - | Splash plate |

| 14 - | Hexagon bolt, 10 Nm |

| 15 - | Hexagon bolt |

| q | For special model “Golf GTI 132 kW”. |

| q | Tightening → Chapter. |

| q | Renew each time after removing. |

| 16 - | Self-locking 12-point nut |

| q | Tightening → Anchor. |

| q | Renew each time after removing. |

| 17 - | Cross-head screw, 4 Nm |

| 18 - | Ventilated brake disc |

| 19 - | Wheel hub with rotor for wheel speed sensor |

| q | Rotor is welded to wheel hub. |

| q | Removing and installing with wheel bearing housing installed → Chapter. |

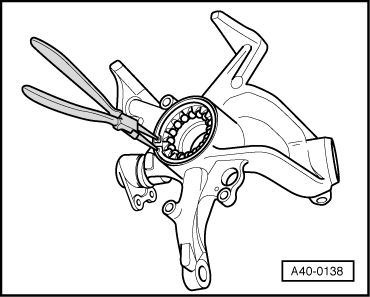

| 20 - | Retaining ring |

| q | Ensure proper seating. |

| 21 - | Wheel bearing |

| q | Pressing out → Fig.. |

| q | Renew, as it is destroyed when pressed out |

| q | Pressing in → Fig.. |

| q | Removing and installing with wheel bearing housing installed → Chapter. |

| 22 - | Wheel bearing housing |

| For vehicles: |

| q | With petrol engines from 110 kW |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|