Golf Mk5

| Adjusting differential |

| Special tools and workshop equipment required |

| t | Gearbox support -VW 353- |

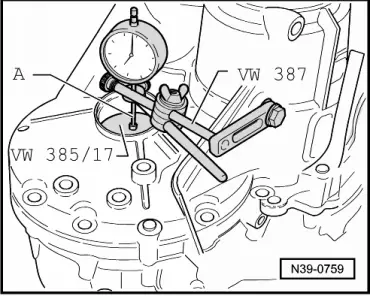

| t | End dimension plate -VW 385/17- |

| t | Universal dial gauge bracket -VW 387- |

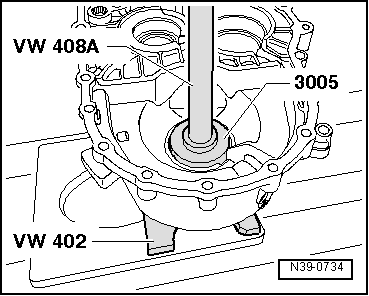

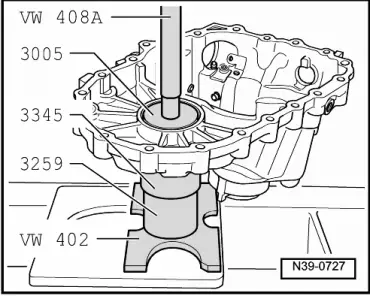

| t | Pressure plate -VW 402- |

| t | Press tool -VW 408 A- |

| t | Thrust plate -3005- |

| t | Tube -3259- |

| t | Tube -3345- |

| t | Torque wrench -V.A.G 1331- |

| t | -1-Internal puller 46 … 58 mm -Kukko 21/7- |

| t | -4-Counter support -Kukko 22/2- |

|

Note

Note

|

|

|

|

|

|