Golf Mk5

| Renewing bevel box output flange oil seal (bevel box removed) |

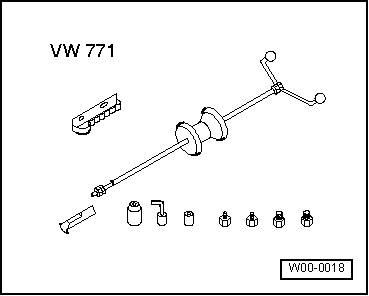

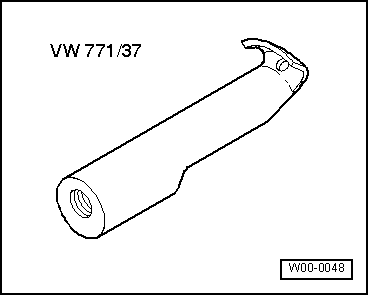

| Special tools and workshop equipment required |

| t | Support clamp -VW 313- |

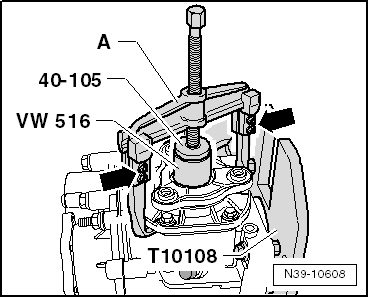

| t | Tube -VW 516- |

| t | Thrust plate -40-105- |

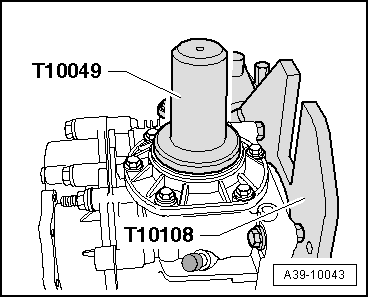

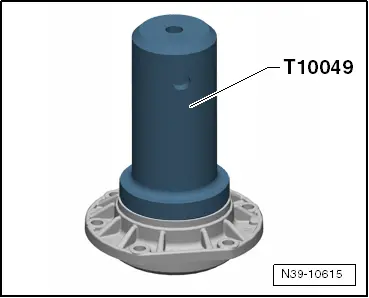

| t | Thrust piece -T10049- |

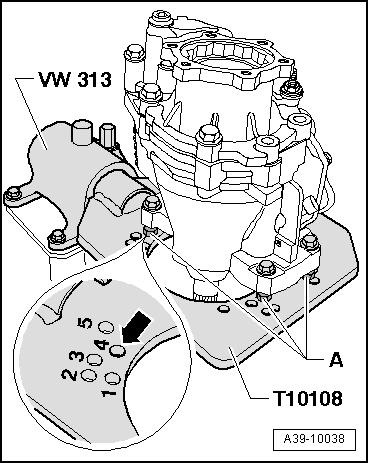

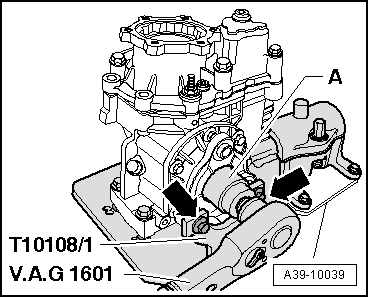

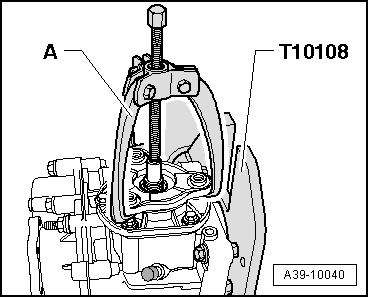

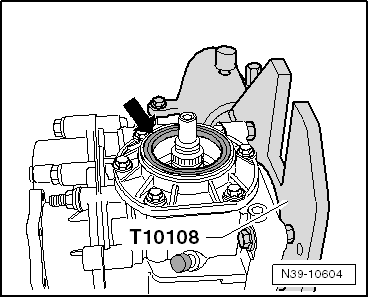

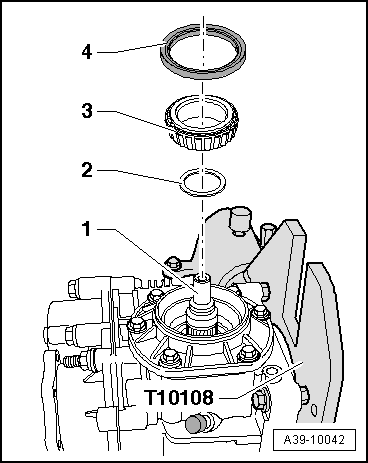

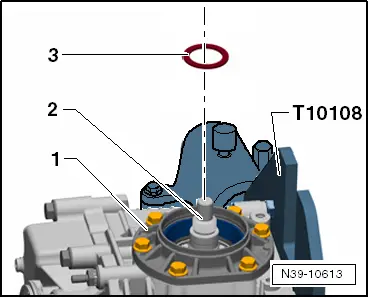

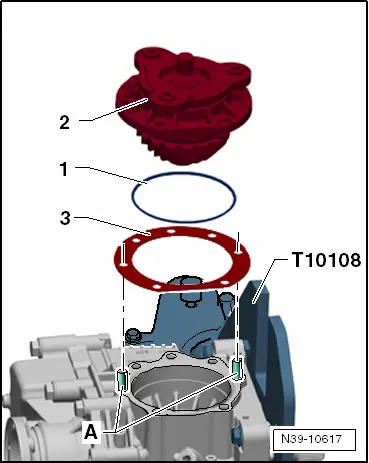

| t | Gearbox support -T10108- |

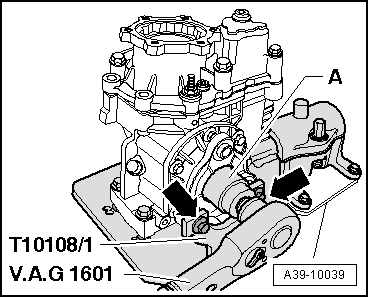

| t | Support plate -T10108/1- |

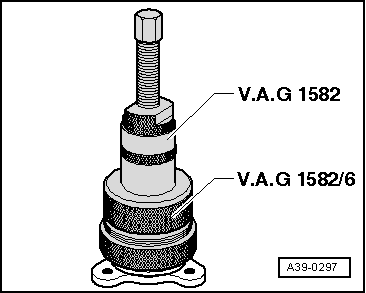

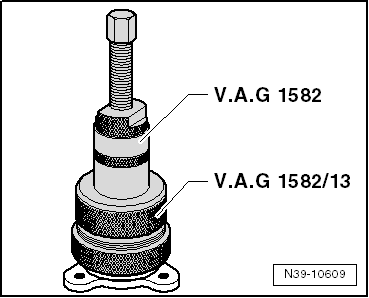

| t | Taper roller bearing puller -V.A.G 1582- with short sleeve |

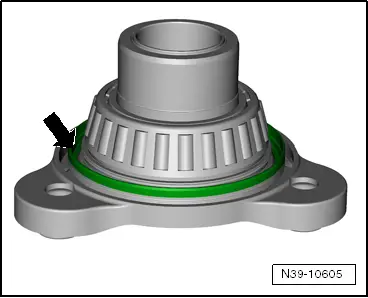

| t | Only for seal in pinion housing → Fig. |

| t | Adapter -V.A.G 1582/6- or Adapter -V.A.G 1582/6A- |

| t | -1-Two arm puller -Kukko 20/10- |

| t | Only for seal on output flange → Fig. |

| t | Adapter -V.A.G 1582/13- |

| t | Continuation for all |

| t | Torque wrench -V.A.G 1601- |

| t | Three arm puller -Kukko 45-2- |

|

|

|

|

|

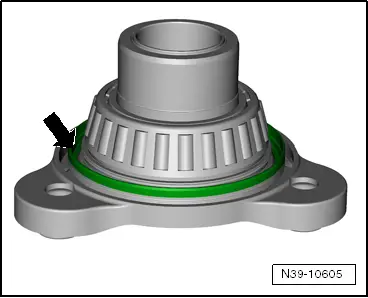

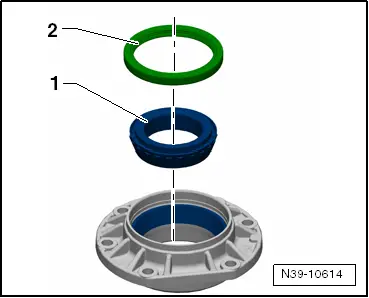

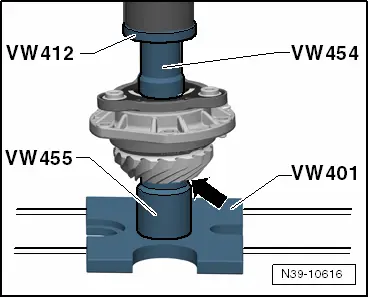

| t | Only for seal on output flange → Fig. |

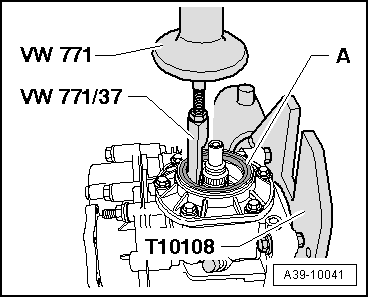

| t | Press tool -VW 412- |

| t | Thrust piece -VW 454- |

| t | Installing sleeve -VW 455- |

| t | Pressure plate -VW 401- |

| t | 2 M 8 X 30 mm stud bolts or M8 guide bolts -T10273- |

| t | Pin -VW 460/2- |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|