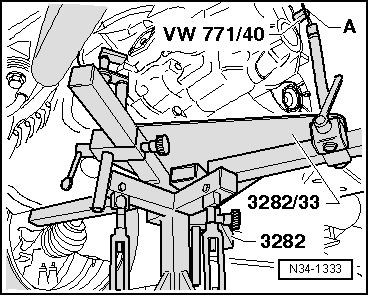

Note | Refer to procedure “Removing gearbox” for required special tools → Chapter. |

Note | t

| When performing repair work, renew self-locking nuts and bolts. |

| t

| Renew bolts which must be tightened to a torque angle. |

| t

| All cable ties which were opened or cut during removal must be renewed at the same points. |

| t

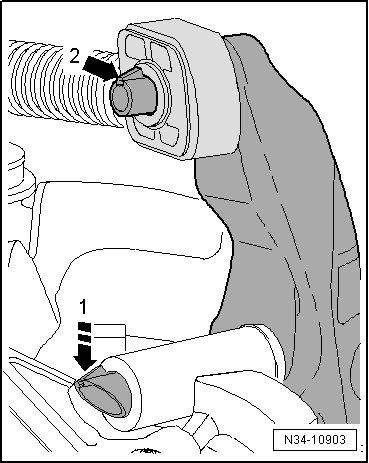

| Clean input shaft splines and, on used clutch plates, clean hub splines; remove corrosion and apply only a very thin coat of clutch plate spline grease -G 000 100- to splines. Then move clutch plate to and fro on input shaft until hub moves freely on shaft. Remove excessive grease. |

| –

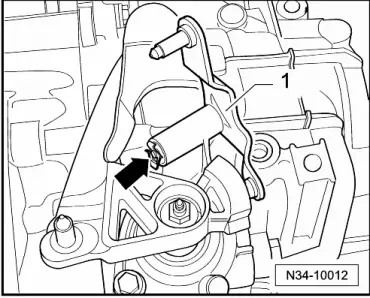

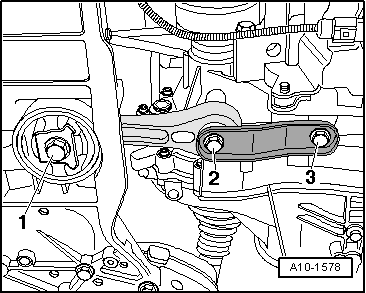

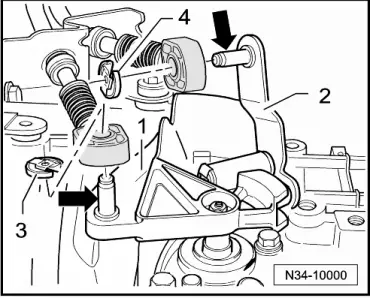

| If the gearbox is to be renewed, the gearbox selector lever and relay lever must be transferred to the new gearbox. |

| –

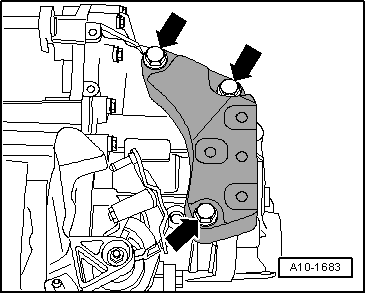

| All threaded holes into which self-locking bolts are to be screwed must be cleaned of residual locking fluid using a thread chaser. |

| –

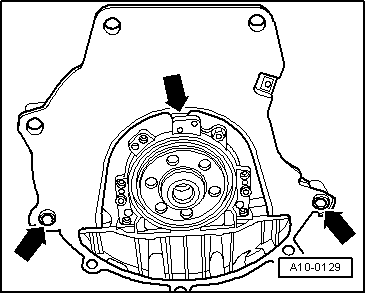

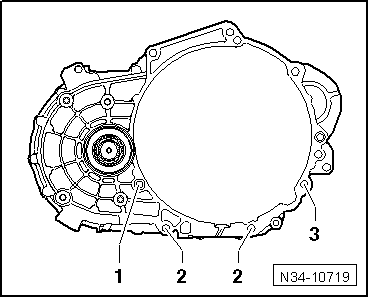

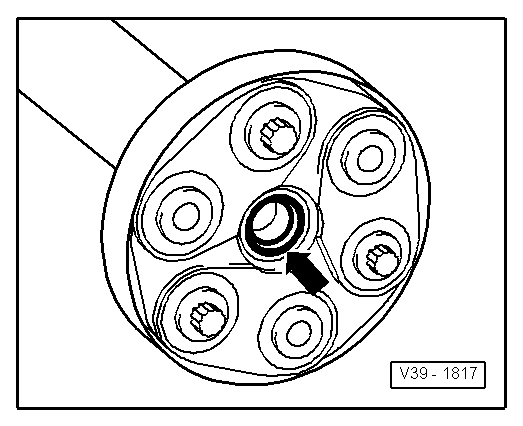

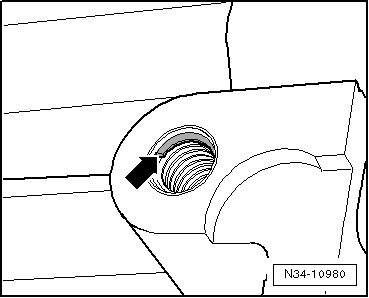

| Check whether dowel sleeves for aligning engine and gearbox are fitted in cylinder block and install if necessary. |

| If dowel sleeves are not fitted, difficulties shifting gears, clutch problems and possible noises from the gearbox (rattling of gears which are not engaged) could occur. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING