| –

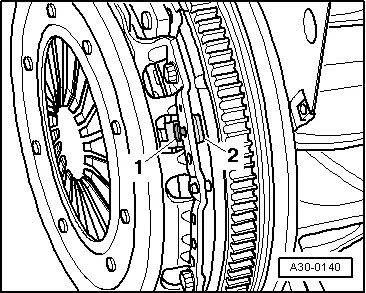

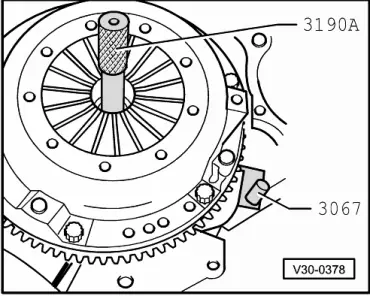

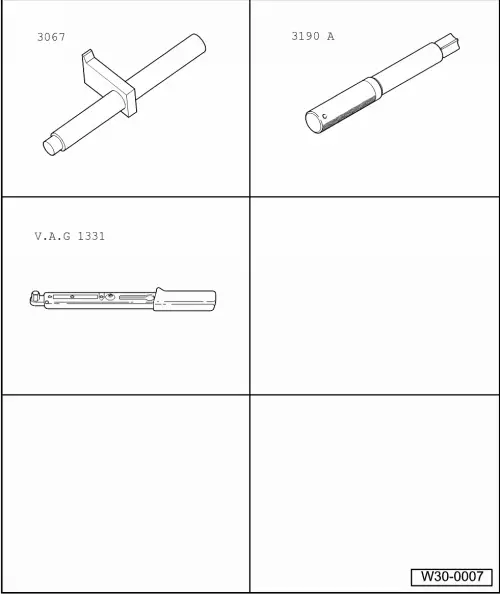

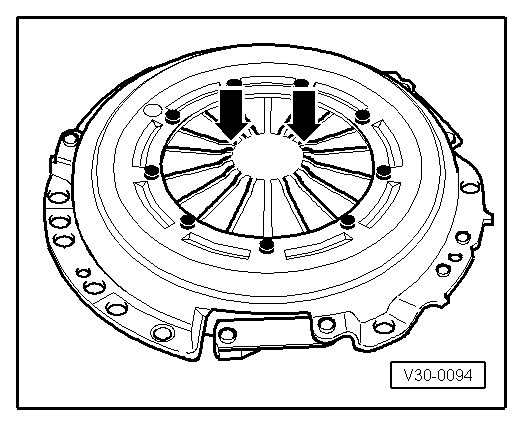

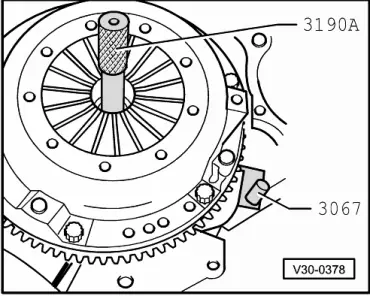

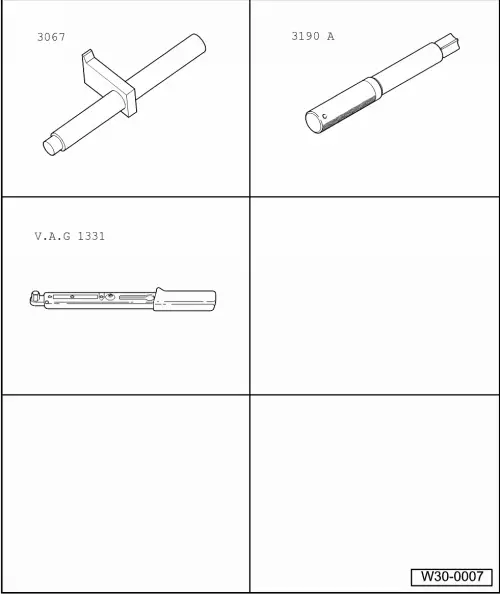

| Loosen bolts in small steps and diagonally. |

| l

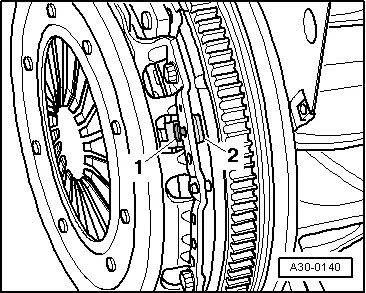

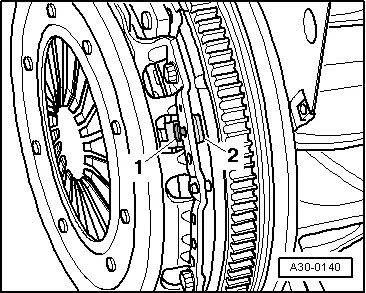

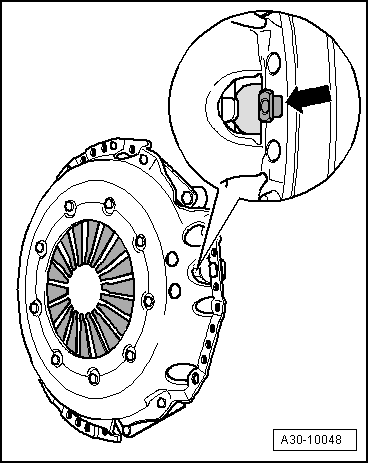

| As bolts are removed, stop -2- with pin -1- must loosen. |

| –

| If stop does not loosen, press pin towards dual-mass flywheel. |

| –

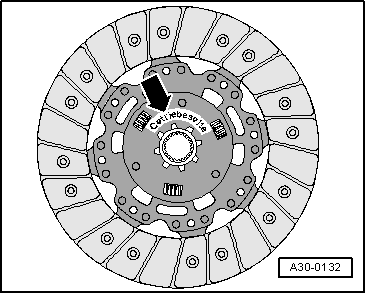

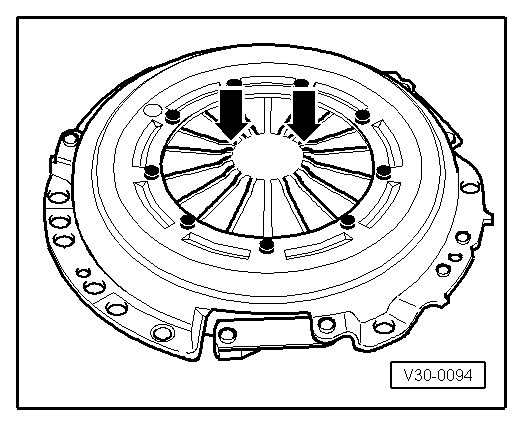

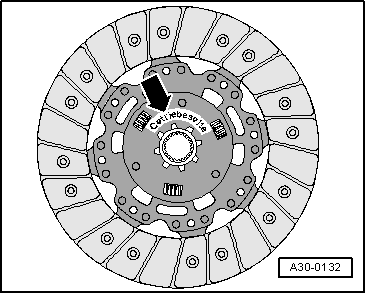

| Remove pressure plate and clutch plate. |

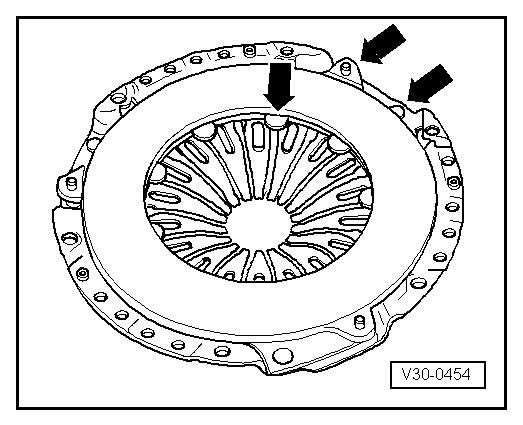

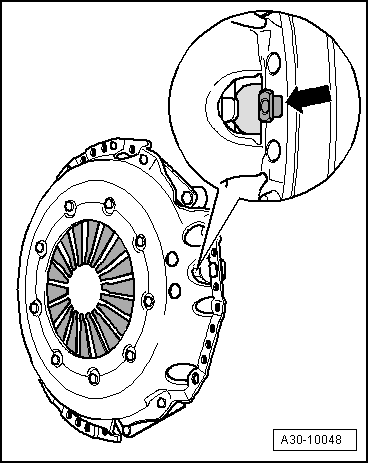

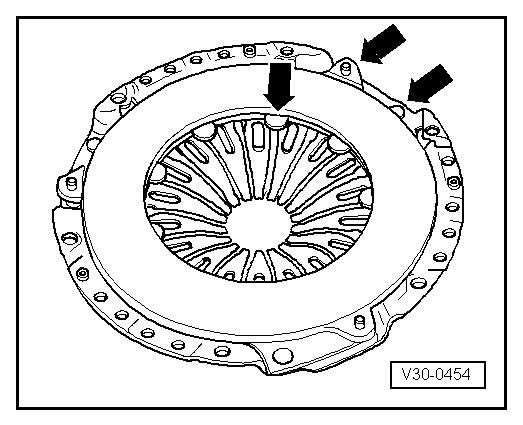

| Install in the reverse order of removal, observing the following: |

Note | t

| Check whether dowel sleeves for aligning engine and gearbox are fitted in cylinder block and install if necessary. |

| t

| If dowel sleeves are not fitted, difficulties shifting gears, clutch problems and possible noises from the gearbox (rattling of gears which are not engaged) could occur. |

|

|

|

Note

Note

Note

Note