Note | –

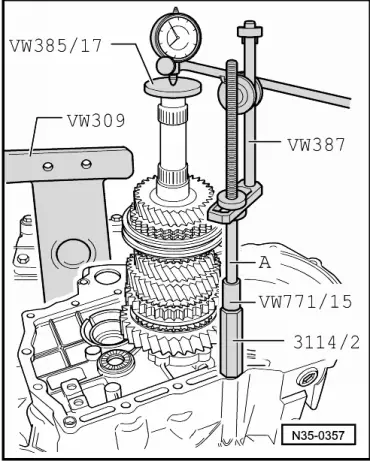

| Remove output shaft and pull out small tapered roller bearing outer race → Fig.. |

| –

| Insert shims of determined thickness, thickest shim first. |

| l

| If the previously used 0.65 mm shim is to be reinstalled, check it for damage. |

| If the size of shim required is larger than those listed in the table, insert two shims totalling the correct figure. |

| The various thicknesses make it possible to achieve the exact shim thickness required. |

| –

| Press in outer race of small tapered roller bearing together with the calculated shim → Fig. and install output shaft. Tighten bearing support nuts in clutch housing to 25 Nm and then turn 90° further. |

|

|

|

Note

Note

Note

Note