Golf Mk5

| Dismantling and assembling input shaft |

| Special tools and workshop equipment required |

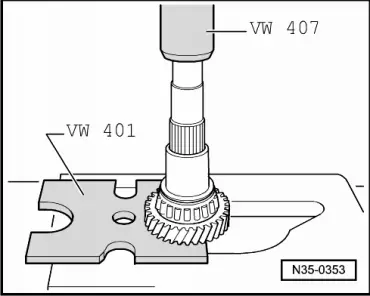

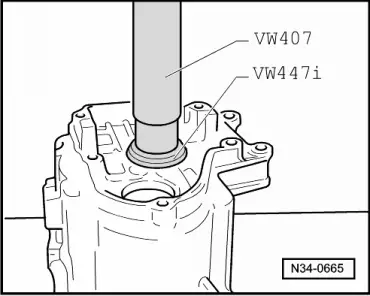

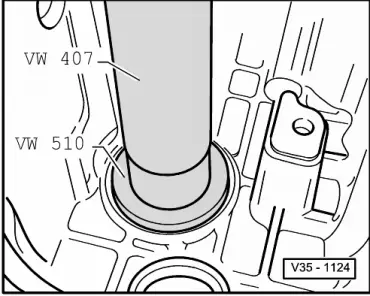

| t | Press tool -VW 407- |

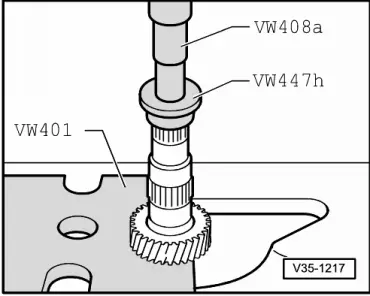

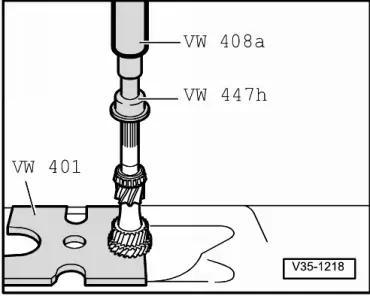

| t | Thrust pad -VW 447 H- |

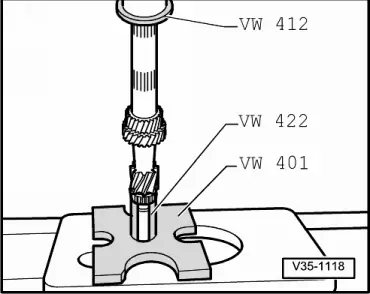

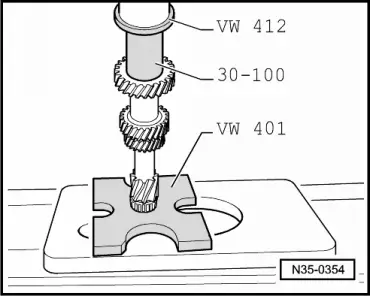

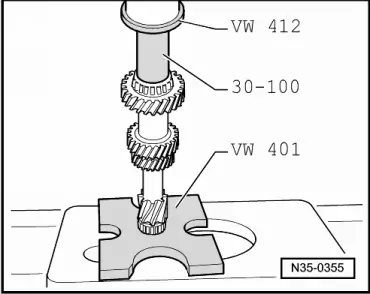

| t | Press tool -VW 412- |

| t | Tube -VW 422- |

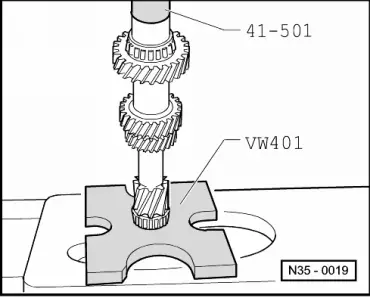

| t | Thrust plate -VW 401- |

| t | Thrust plate -VW 402- |

| t | Press tool -VW 408 A- |

| t | Drift sleeve -41 - 501- |

| t | Thrust pad -VW 447 i- |

| t | Drift sleeve -30 - 100- |

| t | Thrust pad -VW 510- |

| t | Splitter -3 - Kukko 17/1- |

Note

Note| t | When installing new gears, refer to → Electronic parts catalogue “ETKA” and technical data → Chapter. |

| t | If the position of the tapered roller bearings is affected when parts are exchanged, the input shaft must be readjusted. See adjustment overview → Chapter. |

| 1 - | Clutch housing |

| 2 - | Tapered roller bearing outer race |

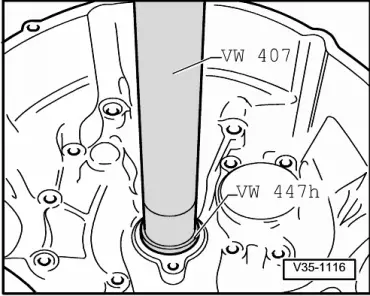

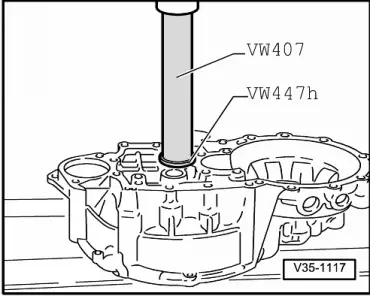

| q | Pressing out → Fig. |

| q | Pressing in → Fig. |

| 3 - | Tapered roller bearing inner race |

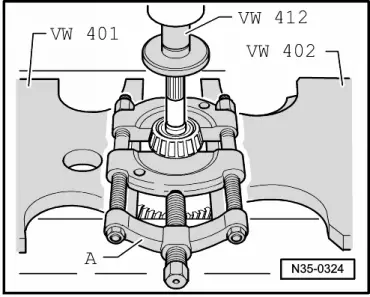

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

| 4 - | Input shaft |

| q | Adjusting → Chapter |

| 5 - | Gear wheel for 3rd gear |

| q | Installation position: shoulder faces 4th gear |

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

| 6 - | Retaining ring |

| q | Always renew |

| 7 - | Gear wheel for 4th gear |

| q | Pressing off with tapered roller bearing outer race and sleeve → Fig. |

| q | Pressing on → Fig. |

| q | Collar faces 3rd gear |

| 8 - | Tapered roller bearing inner race |

| q | Pressing off with gear wheel and sleeve for 4th gear → Fig. |

| q | Pressing on → Fig. |

| 9 - | Thrust washer |

| 10 - | Tapered roller bearing outer race |

| q | Pressing out → Fig. |

| q | Pressing in → Fig. |

| 11 - | Shim |

| q | Determining thickness → Chapter |

| 12 - | Gearbox housing |

| 13 - | Sleeve |

| q | For needle bearing |

| q | Press off with gear wheel for 4th gear and tapered roller bearing inner race → Fig. |

| q | Pressing on → Fig. |

| q | Set thrust washer → Item in place before installing |

| 14 - | Needle bearing |

| 15 - | Synchromeshed gear for 5th gear |

| 16 - | Wave spring washer |

| q | From gearbox date 26 05 8 |

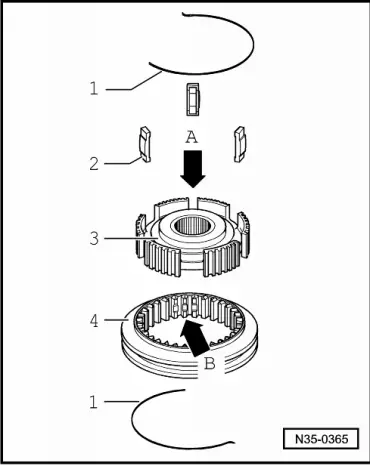

| q | In this case, install only locking piece springs without angled ends. (As shown in → Fig. - item 1-) |

| q | Allocate according to → Electronic parts catalogue “ETKA” |

| 17 - | Synchro-ring for 5th gear |

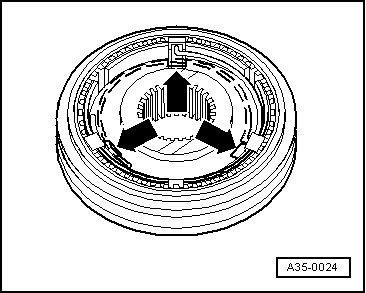

| q | With cast locking pieces → Fig. |

| q | Check for wear → Fig. |

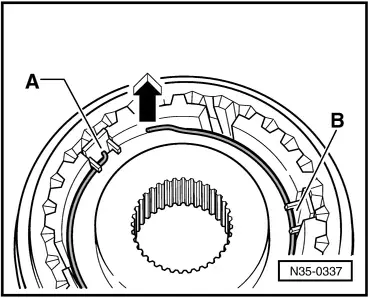

| 18 - | Locking collar with synchro-hub for 5th and 6th gears |

| q | Pull off individually → Chapter |

| q | Pull off together with gearbox housing → Chapter |

| q | Dismantling and assembling → Fig. and → Fig. |

| q | From gearbox date 12 06 6, locking collar modified → Item |

| q | Adjusting 5th and 6th gears, from gearbox date 12 06 6 → Fig. |

| q | Adjusting 5th and 6th gears, through gearbox date 11 06 6 → Fig. |

| q | Installation of springs with angled ends for locking pieces → Fig. |

| 19 - | Synchro-ring for 6th gear |

| q | With cast locking pieces → Fig. |

| q | Check for wear → Fig. |

| 20 - | Wave spring washer |

| q | From gearbox date 26 05 8 |

| q | In this case, install only locking piece springs without angled ends. (As shown in → Fig. - item 1-) |

| q | Allocate according to → Electronic parts catalogue “ETKA” |

| 21 - | Synchromeshed gear for 6th gear → Item |

| 22 - | Needle bearing → Item |

| q | For 6th gear |

| q | Renew together with sleeve |

| 23 - | Sleeve → Item |

| q | For 6th gear needle bearing |

| q | Renew together with needle bearing |

| 24 - | Thrust washer |

| q | Through gearbox date 20 08 6 |

| 25 - | Cylindrical roller bearing inner race |

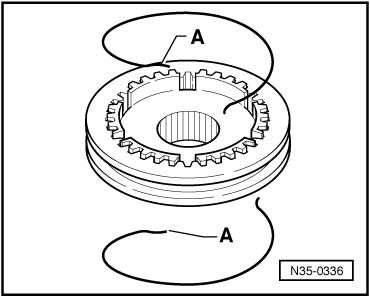

| q | Allocation → Fig. |

| q | Through gearbox date 20 08 6 |

| q | Mark before removing |

| q | Do not interchange with inner race for cylinder roller bearing of output shaft |

| 26 - | Inner race for cylindrical roller bearing with thrust washer |

| q | Allocation → Fig. |

| q | For input shaft |

| q | From gearbox date 21 08 6 |

| 27 - | Bolt → Item |

| q | Allocation → Fig. |

| q | Self-locking |

| q | Always renew |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

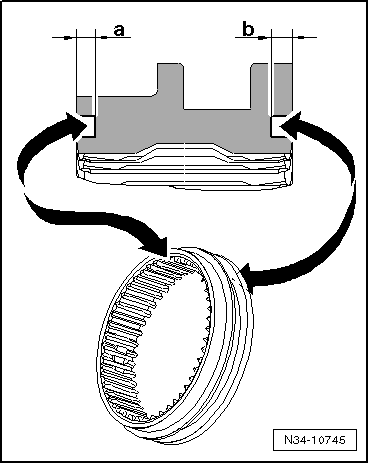

| Dimension -a- (6th gear side) | Through gearbox date 11 06 6 | From gearbox date 12 06 6 |

| 1.5 mm | 1.8 mm |

| Dimension -b- (5th gear side) | Through gearbox date 11 06 6 | From gearbox date 12 06 6 |

| 1.5 mm | 2.0 mm |

|

Note

Note

|

|

|

|

|

|