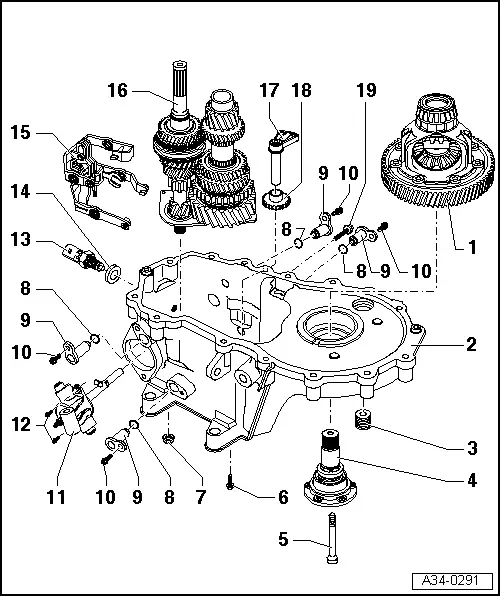

Golf Mk5

| Assembly overview - removing and installing input shaft, output shaft (drive pinion), differential, selector mechanism and selector forks |

| 1 - | Differential |

| q | Dismantling and assembling → Chapter |

| 2 - | Gearbox housing |

| q | Repairing → Chapter |

| q | Shim S1 for outer race of tapered roller bearing for differential from gearbox build date 04 12 6 is discontinued → Fig. |

| q | Bearing seat for tapered roller bearing outer race adapted in gearbox housing |

| 3 - | Oil drain plug, torque setting → Fig. |

| 4 - | Flange shaft with compression spring |

| q | Removing and installing → Chapter |

| q | Assembling → Chapter |

| 5 - | Countersunk bolt |

| q | Removing and installing → Item |

| 6 - | Bolt, 5 Nm + turn 90° further |

| q | Self-locking |

| q | Always renew |

| q | To secure bearing mounting with deep groove ball bearing for input and output shafts → Item. |

| 7 - | Hexagon flange nut, 23 Nm |

| q | For selector mechanism → Item. |

| q | Self-locking |

| q | Always renew |

| 8 - | O-ring |

| q | Always renew |

| 9 - | Pivot pin |

| 10 - | Bolt, 5 Nm + turn 90° further |

| q | Always renew |

| 11 - | Selector shaft with selector shaft cover |

| q | (Selector unit) |

| q | Repairing → Chapter |

| 12 - | Bolt, 5 Nm + turn 90° further |

| q | Always renew |

| 13 - | Reversing light switch -F4-, 20 Nm |

| q | Changed to captive seal shortly after introduction of gearbox. |

| 14 - | Seal |

| q | Not fitted in all gearboxes |

| 15 - | Selector mechanism |

| q | (Selector forks) |

| q | Repairing → Chapter |

| 16 - | Input shaft and output shaft with bearing mounting and deep groove ball bearing |

| q | If bearing mounting is separated from gearbox housing, then mounting must always be renewed. |

| q | Pressing bearing support off and on: Dismantling and assembling input shaft → Item |

| q | Dismantling and assembling input shaft → Chapter |

| q | Dismantling and assembling output shaft → Chapter |

| 17 - | Reverse gear shaft |

| 18 - | Reverse gear wheel |

| 19 - | Bolt, 25 Nm + turn 45° further |

| q | Always renew |

| q | For securing shaft for reverse gear |