| –

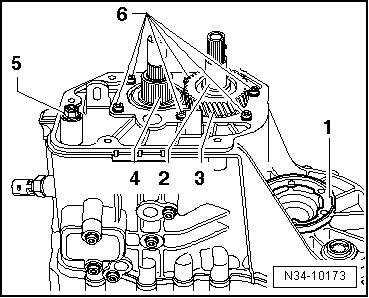

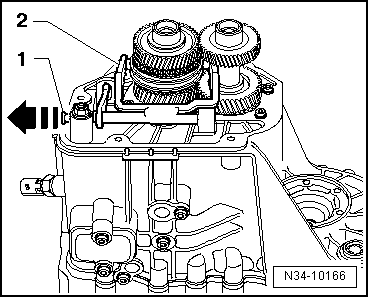

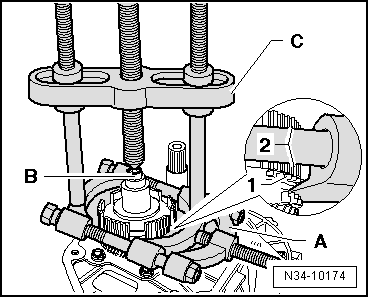

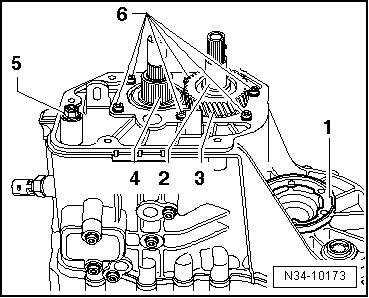

| Pull out flange shaft -1- with spring. |

| –

| Remove sleeve -2-, gear wheel for 5th gear -3- and synchromeshed gear for 5th gear with needle bearing -4-. |

| –

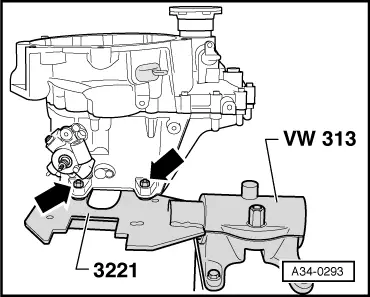

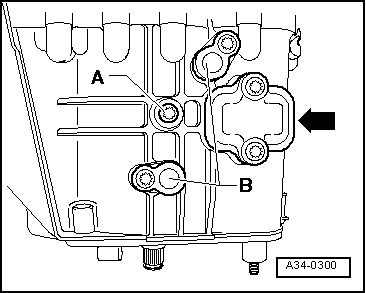

| Unscrew hexagon flange nut -5- for securing reverse gear selector mechanism. |

| –

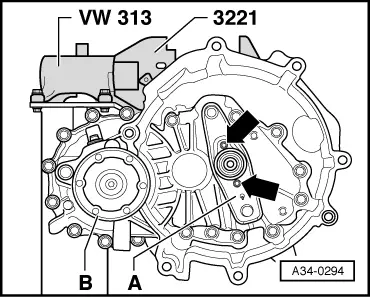

| Remove bearing mounting securing bolts -6- from input and output shafts. |

| –

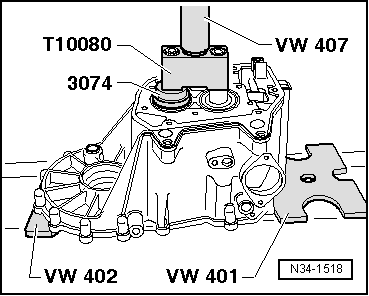

| Turn gearbox in support bracket so that clutch housing is upwards. |

| –

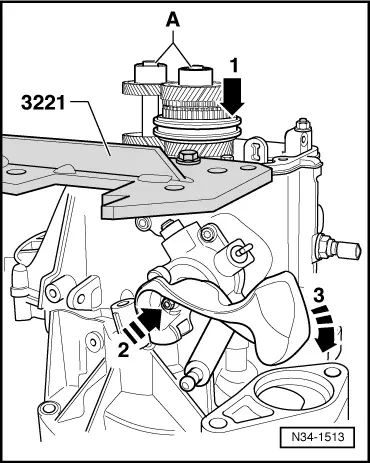

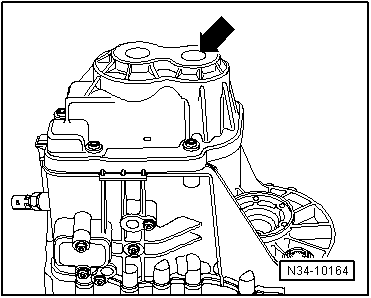

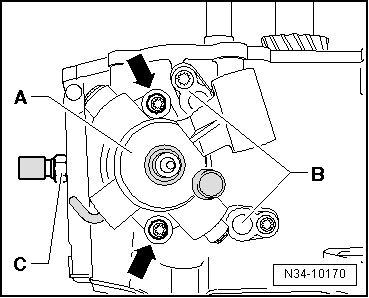

| Remove securing bolts from clutch housing side for securing clutch housing to gearbox housing. |

| –

| Remove clutch housing, if necessary carefully levering up all around along protruding housing flange and alternating between sides, being careful not to damage sealing surfaces. |

| –

| Do not cant the clutch housing. This prevents damage to roller bearings and their bearing seats on the input and output shafts. |

|

|

|

Note

Note

Note

Note

Note

Note